73k miles. Won't go into drive with a bunch of error codes (looks like HV loop disabled). LDU rebuild completed ~ 2weeks ago and driven 350 miles before this problem.

Error codes shows repeated attempts to connect HV (presumably to charge 12V and heat battery?) until 12V got too drained and wouldn't power up the screens. Connected battery charger to jump points behind nose cone and fired up the screen (then got the error codes)

LDU rebuild completed 1+ week ago (leaked rotor seal). Added 2-3L of coolant on reinstall, reservoir puked some out (didn't like being at max) and dumped on top of battery edge seam before adding drain hose to reroute.

Can hear some clicking where the contactors are but not the usual loud contactor sound. Much fainter. My understanding is there is a pre-charge relay that fires and wait for inverter ack before firing the big contactors. Perhaps its the pre-charge relay I hear? I think also hear multiple clicks in sequence (maybe retry?)

Charge port door opens, no light, can't plug in.

Many posts on battery heater failure causing a short on the HV loop preventing from going into drive (besides the obvious suspicion on the contactors or HV battery water ingress) Will try to disconnect HV parts like battery heater and AC compressor to see if culprit. Will pre-charge relay fire if this was the case? Will also inspect inverter underside to see if any coolant presence (none for a few days after LDU reinstall+drive cycle before belly aero pan was installed)

scanmytesla seems to get to all modules including inverter, battery heater temp sensors. So CANBUS looks fine. Battery voltage and BMS all seems to report healthy status.

Does the lighter than usual loud contactor click from the same area provide any clues? Does pre-charge relay even fire if there is a short in HV loop?

Tough one to chase down. No cost effective diag tools is a big barrier for DIYers operating in the blind. Like to avoid Tesla SC but may not be possible on this one (always a frustrating experience dealing with Tesla app service chat and for out of warranty cars)

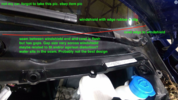

Here are the pics

11/26 (sat) & 11/27 (sun) errors. 11/26 1:38pm is plugging in charger at home after last drive cycle. First attempt to plug mobile charger failed, 2nd attempt succeeded. 11/27 morning error starts ~4am. Looks like repeated attempt to connect HV for 12v bat recharge and/or battery thermal mgmt?

Both pic shows about same error list. First (blurry pic) include the 11/26 1:38pm charger plug error.

Error list and scanmytesla readings after powering up the car this evening (12v charged up and connected, HV fireman loop connect, 12v charger on post behind nose cone) Car powers up, step on brake will turn on head lights, drive info screen shows typical cold battery regen limit.

Error codes shows repeated attempts to connect HV (presumably to charge 12V and heat battery?) until 12V got too drained and wouldn't power up the screens. Connected battery charger to jump points behind nose cone and fired up the screen (then got the error codes)

LDU rebuild completed 1+ week ago (leaked rotor seal). Added 2-3L of coolant on reinstall, reservoir puked some out (didn't like being at max) and dumped on top of battery edge seam before adding drain hose to reroute.

Can hear some clicking where the contactors are but not the usual loud contactor sound. Much fainter. My understanding is there is a pre-charge relay that fires and wait for inverter ack before firing the big contactors. Perhaps its the pre-charge relay I hear? I think also hear multiple clicks in sequence (maybe retry?)

Charge port door opens, no light, can't plug in.

Many posts on battery heater failure causing a short on the HV loop preventing from going into drive (besides the obvious suspicion on the contactors or HV battery water ingress) Will try to disconnect HV parts like battery heater and AC compressor to see if culprit. Will pre-charge relay fire if this was the case? Will also inspect inverter underside to see if any coolant presence (none for a few days after LDU reinstall+drive cycle before belly aero pan was installed)

scanmytesla seems to get to all modules including inverter, battery heater temp sensors. So CANBUS looks fine. Battery voltage and BMS all seems to report healthy status.

Does the lighter than usual loud contactor click from the same area provide any clues? Does pre-charge relay even fire if there is a short in HV loop?

Tough one to chase down. No cost effective diag tools is a big barrier for DIYers operating in the blind. Like to avoid Tesla SC but may not be possible on this one (always a frustrating experience dealing with Tesla app service chat and for out of warranty cars)

Here are the pics

11/26 (sat) & 11/27 (sun) errors. 11/26 1:38pm is plugging in charger at home after last drive cycle. First attempt to plug mobile charger failed, 2nd attempt succeeded. 11/27 morning error starts ~4am. Looks like repeated attempt to connect HV for 12v bat recharge and/or battery thermal mgmt?

Both pic shows about same error list. First (blurry pic) include the 11/26 1:38pm charger plug error.

Error list and scanmytesla readings after powering up the car this evening (12v charged up and connected, HV fireman loop connect, 12v charger on post behind nose cone) Car powers up, step on brake will turn on head lights, drive info screen shows typical cold battery regen limit.

Last edited: