Munro & Associates has just released an analysis of the structural pack for Tesla's 4680 battery cells, having just received a 2022 Model Y SR from Giga Texas.

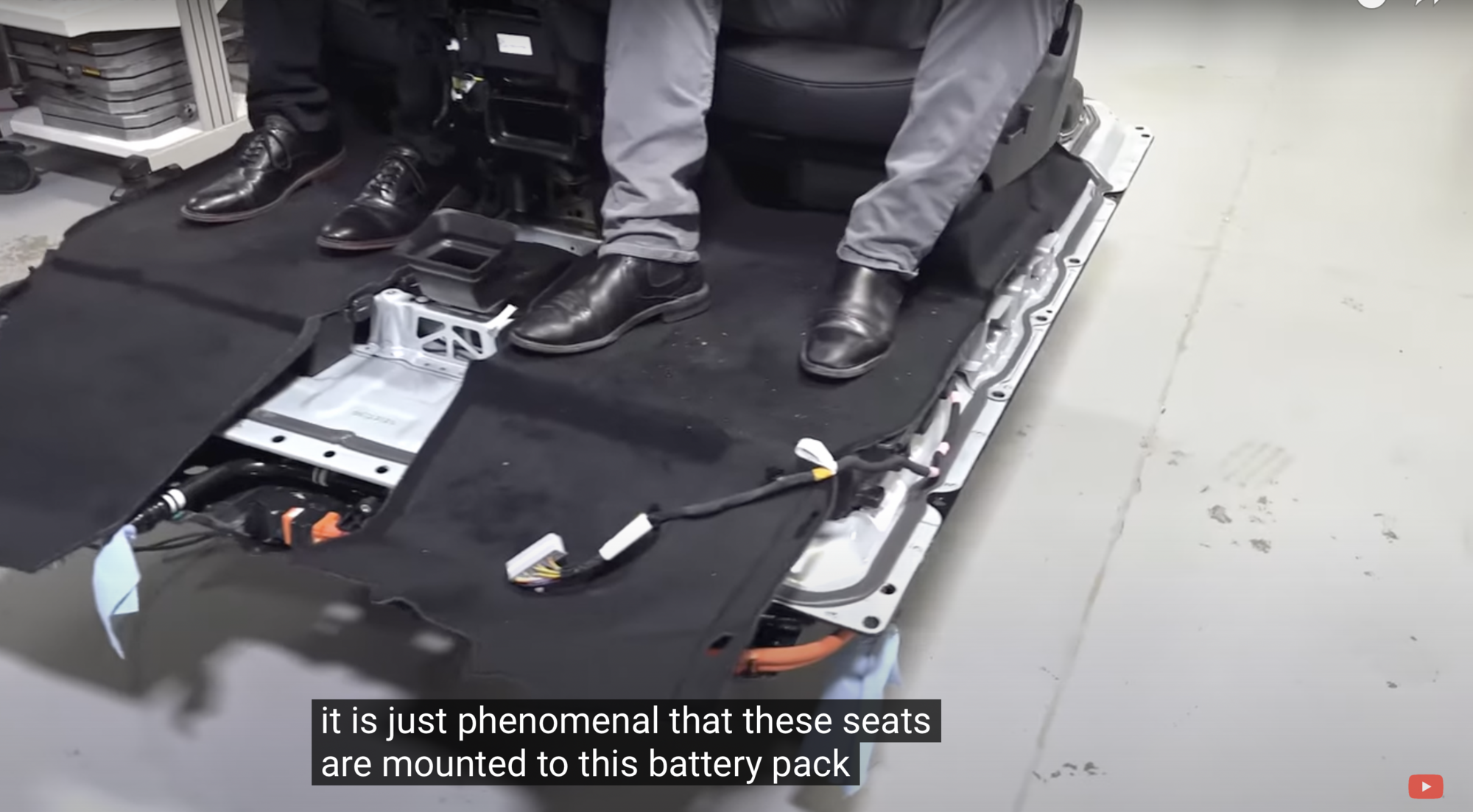

In their analysis, Cory Steuben (President of Munro & Associates) and Julian Aytes (lead engineer) found that the car's front seats are directly mounted onto the structural pack itself, making the structural pack essentially the vehicle's floor itself.

"It's absolutely mind-blowing to be standing under a vehicle on a hoist and have absolutely nothing for the floor structure. To truly understand how amazing it is to see a vehicle with no floor and the seats mounted to the top of the structure on the pack, you have to go back more than years, but decades."

(Source: Munro & Associates)

The structural pack, including the seats and other components mounted to it, weighs 1,198 pounds, which is "incredible because in a couple of the other EVs we have, the batteries will weigh twice that. Just the batteries. No seat, no carpet, no trim."

According to Elon Musk, the structural pack is "the right overall architecture from a physics standpoint, but still far from optimized," which seems to be a modest take on the speed of Tesla's design improvements.

Despite minor manufacturing issues found by the team, the Giga Press casting machines, noted as the world's largest high-pressure die casting machines, have done an amazing job at astronomically decreasing both parts and complexity for the structure of the chassis itself.

"At Munro & Associates, we've seen the development of the automotive industry for the past 30 to 40 years. I've come from a background of benchmarking vehicles where you'd have hundreds of stamped parts where this front giga casting is, and hundreds of parts in the back. The level of refinement and integration is incredible. Tesla is not waiting to integrate the casting for multiple mounting features."

Overall, these improvements have come from decades of constant work and continuous improvement on Tesla's end, and it is clear to see why Tesla is so ahead of many other manufacturers in terms of vehicle and battery structure.

Steuben mentions that the next goal for their analysis is to remove the battery cover and be able to know how Tesla is securing the 4680 cells themselves and take a look inside the battery pack itself.

The full breakdown and analysis is linked below.

In their analysis, Cory Steuben (President of Munro & Associates) and Julian Aytes (lead engineer) found that the car's front seats are directly mounted onto the structural pack itself, making the structural pack essentially the vehicle's floor itself.

"It's absolutely mind-blowing to be standing under a vehicle on a hoist and have absolutely nothing for the floor structure. To truly understand how amazing it is to see a vehicle with no floor and the seats mounted to the top of the structure on the pack, you have to go back more than years, but decades."

(Source: Munro & Associates)

The structural pack, including the seats and other components mounted to it, weighs 1,198 pounds, which is "incredible because in a couple of the other EVs we have, the batteries will weigh twice that. Just the batteries. No seat, no carpet, no trim."

According to Elon Musk, the structural pack is "the right overall architecture from a physics standpoint, but still far from optimized," which seems to be a modest take on the speed of Tesla's design improvements.

Despite minor manufacturing issues found by the team, the Giga Press casting machines, noted as the world's largest high-pressure die casting machines, have done an amazing job at astronomically decreasing both parts and complexity for the structure of the chassis itself.

"At Munro & Associates, we've seen the development of the automotive industry for the past 30 to 40 years. I've come from a background of benchmarking vehicles where you'd have hundreds of stamped parts where this front giga casting is, and hundreds of parts in the back. The level of refinement and integration is incredible. Tesla is not waiting to integrate the casting for multiple mounting features."

Overall, these improvements have come from decades of constant work and continuous improvement on Tesla's end, and it is clear to see why Tesla is so ahead of many other manufacturers in terms of vehicle and battery structure.

Steuben mentions that the next goal for their analysis is to remove the battery cover and be able to know how Tesla is securing the 4680 cells themselves and take a look inside the battery pack itself.

The full breakdown and analysis is linked below.

Last edited: