PecuniaNonOlet

Member

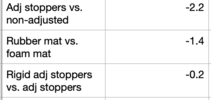

Printed these with Inland PETG+. As I suspected, my usual naughty textured pavement was still boomy. NOT as I suspected, a section of road farther from home I also use to test was eerily silent for the first time ever. So today I learned not only is not all my boom coming from the hatch, different road surfaces will actually trigger different parts of the car to resonate...