4680 batteries, what is the advantage?

4680 is evolutionary, not revolutionary change from what I read.

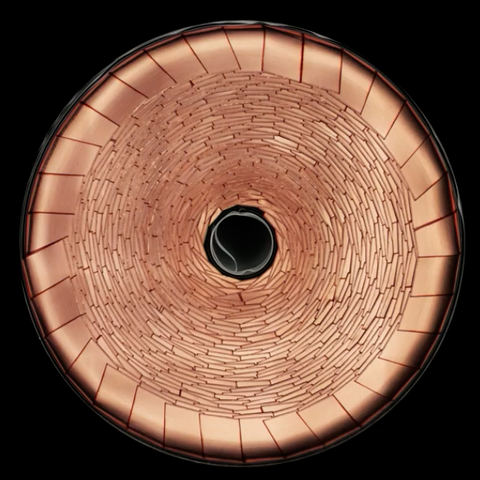

There is little chemical change from other types (18650 and 2170) and uses the same "jellyroll" design. The significant change is size (less so the so called "tabless" design, which IMHO is a "full tab").

From a mfg standpoint, 4680 will be far cheaper since there will be fewer of them needed, one can replace five of the 2170

From a capacity stand point it will be more, again because of size.

A car with 4680 will have more range as a result.

All good, but would a completely different battery design be better, like a Li Ion flat battery?

Or is the integration into a large battery pack make cylindrical design better (eg. better cooling)?

What I do think is Tesla made a safe decision in a design that had a very high chance of success, vs something like "solid state battery" that still is no closer to production than 10 years ago.

When will we see 4680 be installed in cars and PowerWall? 1 Jan 2022?

4680 is evolutionary, not revolutionary change from what I read.

There is little chemical change from other types (18650 and 2170) and uses the same "jellyroll" design. The significant change is size (less so the so called "tabless" design, which IMHO is a "full tab").

From a mfg standpoint, 4680 will be far cheaper since there will be fewer of them needed, one can replace five of the 2170

From a capacity stand point it will be more, again because of size.

A car with 4680 will have more range as a result.

All good, but would a completely different battery design be better, like a Li Ion flat battery?

Or is the integration into a large battery pack make cylindrical design better (eg. better cooling)?

What I do think is Tesla made a safe decision in a design that had a very high chance of success, vs something like "solid state battery" that still is no closer to production than 10 years ago.

When will we see 4680 be installed in cars and PowerWall? 1 Jan 2022?