Hey folks,

Over the last week or so, I've noticed that my air compressor comes on every time I turn the car on after it's been sitting overnight. Obviously there's a leak somewhere.

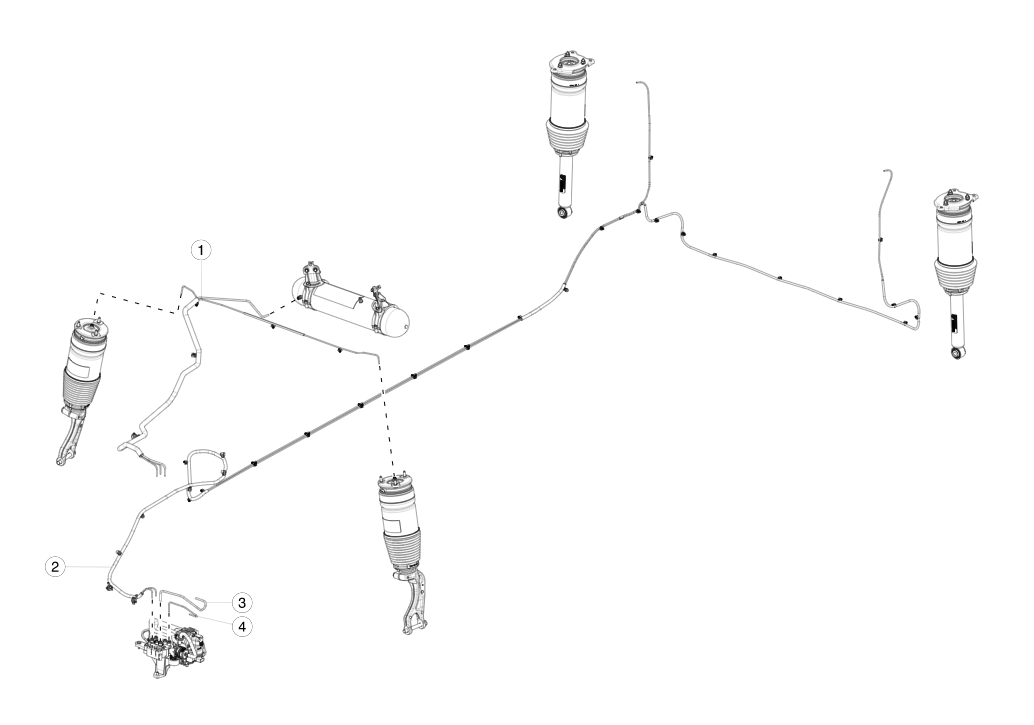

The air shocks maintain pressure, and the car doesn't drop in height - so I'm curious if the leak is between the tank and the compressor.....or maybe #3 or #4 in the diagram below (not really sure of their function).

Curious if anyone else has experienced a leak *before* the valve block that controls air distribution to the struts, and where it ended up being!

Over the last week or so, I've noticed that my air compressor comes on every time I turn the car on after it's been sitting overnight. Obviously there's a leak somewhere.

The air shocks maintain pressure, and the car doesn't drop in height - so I'm curious if the leak is between the tank and the compressor.....or maybe #3 or #4 in the diagram below (not really sure of their function).

Curious if anyone else has experienced a leak *before* the valve block that controls air distribution to the struts, and where it ended up being!