Posted this on TOO but wanted to share some details/pics of my finished install and some observations here as well. LONG READ so here is the TLDR version:

TLDR:

1- Trunk well has more cubic vol thank you might think > a very large 12" sub will fit assuming a sealed box and an optimized design. Gives new meaning to the term "sub-trunk"!

2- Even on a Tesla, 100% of electrical issues and error codes can be avoided if done properly. If you're considering this install (DIY or by a pro) READ UP on the related TOO thread as the info on pg 18-23 is critical to a flawless install.

3- You can creatively solve mounting location challenges by thinking outside the box (literally), scout around the trunk!

4- MaxPider mats make a great subwoofer concealer / protector

5- Took me about a week of free time ~ 5-11pm after work and a full weekend to complete (prep, box, wiring, damping, [re]install ) but was absolutely worth it.

Detailed version:

The main goals of my install were: 1) stealth [appear OEM], 2) damping [increased waveform energy and no rattles], 3- weight savings [haha, right!] and 4) Totally reversible to OEM [not a single wire, panel or inch fabric permanently cut or damaged].

I was nervous for two main reasons. 1) while I've done a ton of complex installs in the past... never on an EV and 2) the irregular shape of the trunk well was somewhat of an enigma to overcome. But what the hell, here it goes!

I re-purposed everything from my old car/install (2012 STi hatch) including components, wiring/fuse blocks, etc. except the PAC-80, 100w resistor and 3a flyback diode (and of course new damping material). I was very doubtful that a sub as monstrous as a 12W7 would fit in the trunk well especially to spec... and figured I'd have to use the main trunk space and lose some storage room due to the box. However to my surprise there was just enough volume in my box design to meet JLs 1.375 cu/ft sealed box spec (after driver displacement). It fit literally just by the skin of it's teeth. Now that it's all said and done it almost seems like this space was designed for a sub box, despite the shape and design challenges.

Components:

- JL Audio 1200/1 class-d amp

- JL Audio 12W7 sub

- Mosconi 6to8 v8 DSP

- AudioCtrl LC2i

Mounting: (everything avail on Amazon)

- Iverntech 700mm 2020 aluminum extrusion

- 2020 extrusion 3-way brackets

- 2020 inside corner brackets

Hardware:

- Knu Kolossus Fleks 4ga power/ground

- Knu Krystal RCA cables

- Knu Kord 10ga speaker wire

- Knu waterproof inline fuse holder (80a)

- PAC-80 (Amazon)

- 2.4Ω 100W aluminum chassis resistor (Amazon)

- IN5404 3A flyback diode from this kit (Amazon)

- 300A inline circuit breaker (Amazon) [used as an emergency 'kill switch']

- Posi-Tap connectors (to tap into stock sub)

- Various 1a inline fuses, wiring, heat shrink tubing, etc

Sub box and custom grille:

1- 3/4" Ultralight MDF (Home Depot)

2- Formular 2" Foam Board (Home Depot)

3- (2) 5mm 2'x4' underlayment panels

4- Absolute speaker carpet (Amazon)

5- JL 12w7-ROD grille

6- Dayton BPA-38G binding posts

6- Gorilla Wood Glue, caulk, screws, etc

Damping: (all Amazon)

1- Noico 80mil deadening mat (36sf)

2- Noico 170mil adhesive backed CCF (36sf)

3- Noico metal barrel roller

Sub Box:

Before I even touched the car I measured the approx volume of a 3/4 MDF box if it were to take up the entire trunk well. Reading @_Travis_ 's blog I found that Tesla shrunk this area significantly with the OEM liner... and while I could have cut a hole to make more room I first wanted to see how much volume was there as-is. It was imperative that the box not sit higher than the rest of the floor and ideally, sat about 1" below so I could add a protective grille over the trunk well. I considered using the OEM well cover for this (or finding a salvaged one) since it's so lightweight... but found a better solution leaving that piece in-tact.

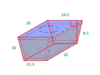

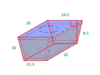

Since the trunk well isn't a perfect cube this part was tricky in that the floor is at a ~10 deg. angle and walls gradually angle outward approx 12.5 deg. I took some rough measurements and used basic Trig to find all angles of the cube and it's volume. Fast-forward, I arrived at 1.51 cu/ft minus driver displacement (.14 cu/ft). I had 1.37 cu/ft taking that away which was just short of JLs spec of 1.375 cu/ft by 5/1000s of a cubic foot. Close enough!

I'll post more detailed pics of the box later, but here's a rough diagram and the end result sitting in the trunk well. Mission mostly accomplished.

- A note on speaker carpet. I used PolyMat black for the box itself but it didn't match the OEM carpet AT ALL. I did some research and I found that this Absolute speaker carpet (Amazon) looks pretty damn close to stock, so I used this on the custom grill since it's the only carpeted part that will show... and wasn't about to pull the old carpet off the box and re-wrap it. More on this below...

Prep:

In a nutshell, used this blog to disassemble the back half of the interior/trunk. It was really pretty easy and only took maybe 1-2 hours with the seats, liners, etc to expose bare metal on all sides. I wrapped everything in protective film to prevent scratches and preserve that "new Tesla smell" and stored it in the next room. All there really was to it!

Custom grille:

I wanted to protect this monster driver so I built a custom grill that fits identical to the OEM well cover. As you can see in the pic above, while the box itself fit perfect the surround on the sub extrudes about 1.". I needed to find a solution that protected the sub without sitting much higher, AND had to account for cone linear excursion (1.15" Xmax). On top of this (literally) there had to be enough room for my new MaxPider trunk mat to fit, returning the trunk to a stealthy, OEM appearance. Seemed impossible at this point but what the hell, again here it goes!

I first cut out a piece of MDF in the shape of the OEM trunk well, but realized I'd have to glue 2 or 3 of these together to be thick/high enough and the weight added up quickly being solid core board (~11.5 lbs).

Instead, I ditched the MDF and started looking at foam core boards. Foam core would be wayyy lighter but everything I could find was too pricey ($50+) and nowhere thick enough (1" or so max). Then I remembered the foam core panels used in building construction and found that the Formular 2" Foam Board at Home Depot was the perfect width and weight for the job. It wasn't very sturdy so I mated it with a (2) 5mm 2'x4' underlayment panel cut to shape and glued to each side, then carpeted.

End result was a perfect fit, 2.4" thick and ~2.3 lb saving me nearly ten pounds over lightweight MDF!

Once wrapped with the Absolut carpet I was pretty happy with the color match to the OEM carpet:

Components/wiring:

With the box done, it was time to tackle the components and wiring. I'll be honest this made me a bit nervous so I did a lot of research during the box phase... and have to say pages ~18-23 of this thread are a lifesaver! I do not think it would have gone that smoothly without the extreme attention to detail you all provided in your posts. So thank you!

Anyway, I didn't want to mount expensive components in the trunk well (had no room anyway) nor did I want to use up valuable trunk space. My only real option was the trunk ceiling. How the hell would I tackle this though? Velcro? Haha, well....

I scouted around the trunk area and found the back seat latches had about 10 threads to work with on the trunk side. Measuring across these I found two were almost exactly 10" wide from bolt to bolt. This part is just dumb luck but the HD 1200/1 is also almost 10" across on the mounting feet. Why not build a small cage from aluminum extrusion (same stuff 3d printer frames are built from) and mount it to the ceiling? It might work but how to mount on the other side?

It turns out the frame cross-member across and above the wheel wells was just the right location... it just need a couple of VERY small pilot holes to accommodate some self-tapping bolts. Okay, this is where I violate goal #4. I had to drill 2 tiny pilot holes into this cross-member for this to work but at this point it was a sacrifice worth taking (they are really small). Some more cutting, filing and connecting and I had the perfect Amp rack. The Lc2i and 6to8 are so light I ended up using industrial strength velcro to attach them to the cross member.

At this point I really just followed the diagram in this post which was a hybrid of diagrams earlier in the thread. I'm on day 5 now and have yet to see a single dingle error message, hear a thump, burn a fuse or smell anything burning. Woohoo!

Damping:

EDIT: I also forgot to mention that I did sound damping (Noico) along the way. I started with felt tape to cover off any rattles that I found using a tone generator, then did 25% coverage with butyl damping in key areas from the battery back and 100% coverage of CCF including wheel wells, trunk ceiling, penthouse and motor. I didn't do MLV due to the weight ... and some will argue you need MLV or it makes no audible difference. I disagree completely.

I've done the full sandwich of CLD tiles, CCF and 1lb/sqft MLV in my STI and hardly noticed a difference. In the Model 3, even without MLV the difference is night and day. Maybe this is because I drove the car with the back trim removed for a week, or maybe because damping the wheel wells actually helps. Either way IMO it now is as quiet as I had hoped for on delivery day (but sadly was not). Minus a little tire noise it's dead silent and I love it! Music is so much more enjoyable to listen to and conversations both in-car and via bluetooth only need about 2/10 volume to be audible. Plus all those annoying %@#$ rattles are finally gone!

(re)Install:

The system is tested (by ear, not mic... yet) and sounds 1000% times better. Very happy with the results. Time to button it up and cross my fingers to see if the MaxPider mat still fits or if it looks like a cancerous lump in the trunk floor...

Cha-ching! Profit!

That's about it. Sorry for the long read but thanks for doing so. Hopefully there are a few helpful hints for those of you thinking/planning to take this install on yourself.

TLDR:

1- Trunk well has more cubic vol thank you might think > a very large 12" sub will fit assuming a sealed box and an optimized design. Gives new meaning to the term "sub-trunk"!

2- Even on a Tesla, 100% of electrical issues and error codes can be avoided if done properly. If you're considering this install (DIY or by a pro) READ UP on the related TOO thread as the info on pg 18-23 is critical to a flawless install.

3- You can creatively solve mounting location challenges by thinking outside the box (literally), scout around the trunk!

4- MaxPider mats make a great subwoofer concealer / protector

5- Took me about a week of free time ~ 5-11pm after work and a full weekend to complete (prep, box, wiring, damping, [re]install ) but was absolutely worth it.

Detailed version:

The main goals of my install were: 1) stealth [appear OEM], 2) damping [increased waveform energy and no rattles], 3- weight savings [haha, right!] and 4) Totally reversible to OEM [not a single wire, panel or inch fabric permanently cut or damaged].

I was nervous for two main reasons. 1) while I've done a ton of complex installs in the past... never on an EV and 2) the irregular shape of the trunk well was somewhat of an enigma to overcome. But what the hell, here it goes!

I re-purposed everything from my old car/install (2012 STi hatch) including components, wiring/fuse blocks, etc. except the PAC-80, 100w resistor and 3a flyback diode (and of course new damping material). I was very doubtful that a sub as monstrous as a 12W7 would fit in the trunk well especially to spec... and figured I'd have to use the main trunk space and lose some storage room due to the box. However to my surprise there was just enough volume in my box design to meet JLs 1.375 cu/ft sealed box spec (after driver displacement). It fit literally just by the skin of it's teeth. Now that it's all said and done it almost seems like this space was designed for a sub box, despite the shape and design challenges.

Components:

- JL Audio 1200/1 class-d amp

- JL Audio 12W7 sub

- Mosconi 6to8 v8 DSP

- AudioCtrl LC2i

Mounting: (everything avail on Amazon)

- Iverntech 700mm 2020 aluminum extrusion

- 2020 extrusion 3-way brackets

- 2020 inside corner brackets

Hardware:

- Knu Kolossus Fleks 4ga power/ground

- Knu Krystal RCA cables

- Knu Kord 10ga speaker wire

- Knu waterproof inline fuse holder (80a)

- PAC-80 (Amazon)

- 2.4Ω 100W aluminum chassis resistor (Amazon)

- IN5404 3A flyback diode from this kit (Amazon)

- 300A inline circuit breaker (Amazon) [used as an emergency 'kill switch']

- Posi-Tap connectors (to tap into stock sub)

- Various 1a inline fuses, wiring, heat shrink tubing, etc

Sub box and custom grille:

1- 3/4" Ultralight MDF (Home Depot)

2- Formular 2" Foam Board (Home Depot)

3- (2) 5mm 2'x4' underlayment panels

4- Absolute speaker carpet (Amazon)

5- JL 12w7-ROD grille

6- Dayton BPA-38G binding posts

6- Gorilla Wood Glue, caulk, screws, etc

Damping: (all Amazon)

1- Noico 80mil deadening mat (36sf)

2- Noico 170mil adhesive backed CCF (36sf)

3- Noico metal barrel roller

Sub Box:

Before I even touched the car I measured the approx volume of a 3/4 MDF box if it were to take up the entire trunk well. Reading @_Travis_ 's blog I found that Tesla shrunk this area significantly with the OEM liner... and while I could have cut a hole to make more room I first wanted to see how much volume was there as-is. It was imperative that the box not sit higher than the rest of the floor and ideally, sat about 1" below so I could add a protective grille over the trunk well. I considered using the OEM well cover for this (or finding a salvaged one) since it's so lightweight... but found a better solution leaving that piece in-tact.

Since the trunk well isn't a perfect cube this part was tricky in that the floor is at a ~10 deg. angle and walls gradually angle outward approx 12.5 deg. I took some rough measurements and used basic Trig to find all angles of the cube and it's volume. Fast-forward, I arrived at 1.51 cu/ft minus driver displacement (.14 cu/ft). I had 1.37 cu/ft taking that away which was just short of JLs spec of 1.375 cu/ft by 5/1000s of a cubic foot. Close enough!

I'll post more detailed pics of the box later, but here's a rough diagram and the end result sitting in the trunk well. Mission mostly accomplished.

- A note on speaker carpet. I used PolyMat black for the box itself but it didn't match the OEM carpet AT ALL. I did some research and I found that this Absolute speaker carpet (Amazon) looks pretty damn close to stock, so I used this on the custom grill since it's the only carpeted part that will show... and wasn't about to pull the old carpet off the box and re-wrap it. More on this below...

Prep:

In a nutshell, used this blog to disassemble the back half of the interior/trunk. It was really pretty easy and only took maybe 1-2 hours with the seats, liners, etc to expose bare metal on all sides. I wrapped everything in protective film to prevent scratches and preserve that "new Tesla smell" and stored it in the next room. All there really was to it!

Custom grille:

I wanted to protect this monster driver so I built a custom grill that fits identical to the OEM well cover. As you can see in the pic above, while the box itself fit perfect the surround on the sub extrudes about 1.". I needed to find a solution that protected the sub without sitting much higher, AND had to account for cone linear excursion (1.15" Xmax). On top of this (literally) there had to be enough room for my new MaxPider trunk mat to fit, returning the trunk to a stealthy, OEM appearance. Seemed impossible at this point but what the hell, again here it goes!

I first cut out a piece of MDF in the shape of the OEM trunk well, but realized I'd have to glue 2 or 3 of these together to be thick/high enough and the weight added up quickly being solid core board (~11.5 lbs).

Instead, I ditched the MDF and started looking at foam core boards. Foam core would be wayyy lighter but everything I could find was too pricey ($50+) and nowhere thick enough (1" or so max). Then I remembered the foam core panels used in building construction and found that the Formular 2" Foam Board at Home Depot was the perfect width and weight for the job. It wasn't very sturdy so I mated it with a (2) 5mm 2'x4' underlayment panel cut to shape and glued to each side, then carpeted.

End result was a perfect fit, 2.4" thick and ~2.3 lb saving me nearly ten pounds over lightweight MDF!

Once wrapped with the Absolut carpet I was pretty happy with the color match to the OEM carpet:

Components/wiring:

With the box done, it was time to tackle the components and wiring. I'll be honest this made me a bit nervous so I did a lot of research during the box phase... and have to say pages ~18-23 of this thread are a lifesaver! I do not think it would have gone that smoothly without the extreme attention to detail you all provided in your posts. So thank you!

Anyway, I didn't want to mount expensive components in the trunk well (had no room anyway) nor did I want to use up valuable trunk space. My only real option was the trunk ceiling. How the hell would I tackle this though? Velcro? Haha, well....

I scouted around the trunk area and found the back seat latches had about 10 threads to work with on the trunk side. Measuring across these I found two were almost exactly 10" wide from bolt to bolt. This part is just dumb luck but the HD 1200/1 is also almost 10" across on the mounting feet. Why not build a small cage from aluminum extrusion (same stuff 3d printer frames are built from) and mount it to the ceiling? It might work but how to mount on the other side?

It turns out the frame cross-member across and above the wheel wells was just the right location... it just need a couple of VERY small pilot holes to accommodate some self-tapping bolts. Okay, this is where I violate goal #4. I had to drill 2 tiny pilot holes into this cross-member for this to work but at this point it was a sacrifice worth taking (they are really small). Some more cutting, filing and connecting and I had the perfect Amp rack. The Lc2i and 6to8 are so light I ended up using industrial strength velcro to attach them to the cross member.

At this point I really just followed the diagram in this post which was a hybrid of diagrams earlier in the thread. I'm on day 5 now and have yet to see a single dingle error message, hear a thump, burn a fuse or smell anything burning. Woohoo!

Damping:

EDIT: I also forgot to mention that I did sound damping (Noico) along the way. I started with felt tape to cover off any rattles that I found using a tone generator, then did 25% coverage with butyl damping in key areas from the battery back and 100% coverage of CCF including wheel wells, trunk ceiling, penthouse and motor. I didn't do MLV due to the weight ... and some will argue you need MLV or it makes no audible difference. I disagree completely.

I've done the full sandwich of CLD tiles, CCF and 1lb/sqft MLV in my STI and hardly noticed a difference. In the Model 3, even without MLV the difference is night and day. Maybe this is because I drove the car with the back trim removed for a week, or maybe because damping the wheel wells actually helps. Either way IMO it now is as quiet as I had hoped for on delivery day (but sadly was not). Minus a little tire noise it's dead silent and I love it! Music is so much more enjoyable to listen to and conversations both in-car and via bluetooth only need about 2/10 volume to be audible. Plus all those annoying %@#$ rattles are finally gone!

(re)Install:

The system is tested (by ear, not mic... yet) and sounds 1000% times better. Very happy with the results. Time to button it up and cross my fingers to see if the MaxPider mat still fits or if it looks like a cancerous lump in the trunk floor...

Cha-ching! Profit!

That's about it. Sorry for the long read but thanks for doing so. Hopefully there are a few helpful hints for those of you thinking/planning to take this install on yourself.

Last edited: