I brought the two Model 3's back to VIR last weekend. The weather was excellent, and the cars performed superbly.

I set PB's in both cars. 2:08.08 in the Black Model 3 and 2:08.8 in the Red Model 3. I left a second or two on the table in the Black car, but had a lot less open track to work with. The tires are also at the end of their life, so that is slowing me down some.

The Red Model 3 had been fitted with the MPP.R StopTech STR-60 BBK. It was paired with Raybestos ST-45 Pads and fresh Motul RBF600 brake fluid. Braking was far superior to the stock setup. The pedal was firm and consistent throughout the day, and inspired a lot more confidence. Braking was quick and linear during deceleration, no more squishy pedal or delayed responses. No overheating occurred, and they look pretty awesome too! Street manners are quite nice, they don't make any strange noises and they shouldn't require frequent rebuilds. Overall, a highly recommended upgrade for anyone seriously tracking their 3!

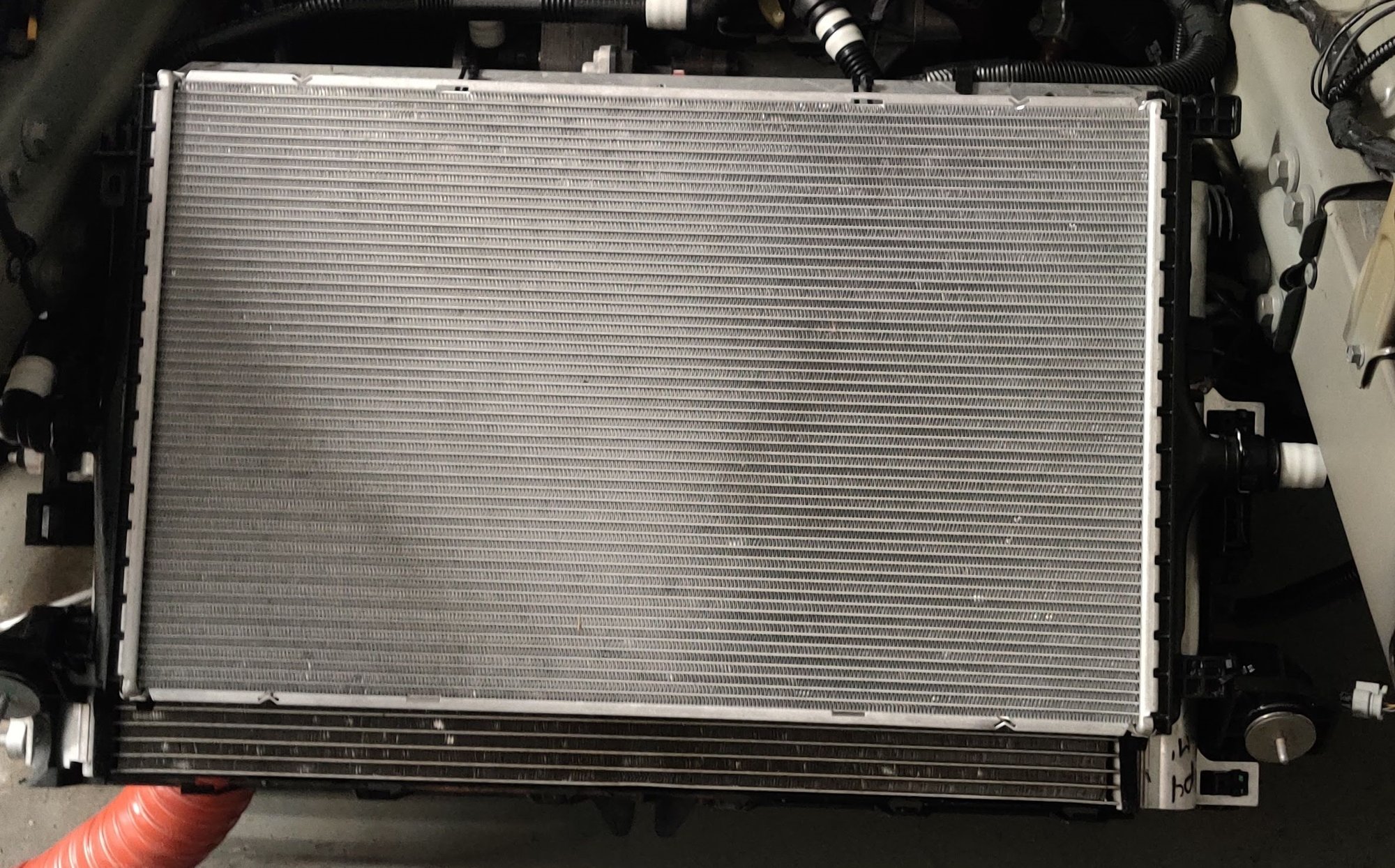

As some of you know, I installed a prototype radiator into the Black Model 3. It performed well - no leaks, and it did its job. It did not resolve the power current reduction issue entirely, though it helped some. When comparing the two cars back to back, drive unit inverter temperatures were roughly 8% less (peak), and the car was able to be driven ~20% longer before current was pulled. There is still work to be done, and work has begun on some more modifications to improve this. The ultimate goal would be to eliminate this problem entirely so we can enjoy full sessions like those ICE cars.

Overall, I continue to be amazed at how well the Model 3 handles. It can keep up with basically anything in the corners. You would never guess it is so heavy given how agile it is. I did find a 45/55 bias to be the sweet spot for my driving style. 50/50 resulted in a little bit of understeer, and 40/60 resulted in a little bit of oversteer. Traction is set to -10. I played around with reduced regenerative braking but it didn't seem to help the power current reduction much and did result in the battery consumption increasing even more. At 100% regen braking I am at about 1,500wh/mi, at 75% that increased to about 1,650wh/mi.

The weak spot of the Model 3 continues to be speeds over ~110mph. Up to that point, there isn't much that will pull on it, but the Corvette's, 911's, and other high horsepower cars pull away quickly as speeds increase. VIR is a high speed track where the car would benefit from a 2nd gear, but it is what it is.

Along with solving the power current issue, I am looking to put in some lightweight seats this offseason and some R-Compound tires. I believe a sub 2:05 at VIR is very achievable at that point. After that, we may need to go Plaid for some sub 2:00 laps.

Here is my 2:08.08 in the Black Model 3:

And the 2:08.8 in the Red Model 3, with some 911 Turbo overtaking included:

I set PB's in both cars. 2:08.08 in the Black Model 3 and 2:08.8 in the Red Model 3. I left a second or two on the table in the Black car, but had a lot less open track to work with. The tires are also at the end of their life, so that is slowing me down some.

The Red Model 3 had been fitted with the MPP.R StopTech STR-60 BBK. It was paired with Raybestos ST-45 Pads and fresh Motul RBF600 brake fluid. Braking was far superior to the stock setup. The pedal was firm and consistent throughout the day, and inspired a lot more confidence. Braking was quick and linear during deceleration, no more squishy pedal or delayed responses. No overheating occurred, and they look pretty awesome too! Street manners are quite nice, they don't make any strange noises and they shouldn't require frequent rebuilds. Overall, a highly recommended upgrade for anyone seriously tracking their 3!

As some of you know, I installed a prototype radiator into the Black Model 3. It performed well - no leaks, and it did its job. It did not resolve the power current reduction issue entirely, though it helped some. When comparing the two cars back to back, drive unit inverter temperatures were roughly 8% less (peak), and the car was able to be driven ~20% longer before current was pulled. There is still work to be done, and work has begun on some more modifications to improve this. The ultimate goal would be to eliminate this problem entirely so we can enjoy full sessions like those ICE cars.

Overall, I continue to be amazed at how well the Model 3 handles. It can keep up with basically anything in the corners. You would never guess it is so heavy given how agile it is. I did find a 45/55 bias to be the sweet spot for my driving style. 50/50 resulted in a little bit of understeer, and 40/60 resulted in a little bit of oversteer. Traction is set to -10. I played around with reduced regenerative braking but it didn't seem to help the power current reduction much and did result in the battery consumption increasing even more. At 100% regen braking I am at about 1,500wh/mi, at 75% that increased to about 1,650wh/mi.

The weak spot of the Model 3 continues to be speeds over ~110mph. Up to that point, there isn't much that will pull on it, but the Corvette's, 911's, and other high horsepower cars pull away quickly as speeds increase. VIR is a high speed track where the car would benefit from a 2nd gear, but it is what it is.

Along with solving the power current issue, I am looking to put in some lightweight seats this offseason and some R-Compound tires. I believe a sub 2:05 at VIR is very achievable at that point. After that, we may need to go Plaid for some sub 2:00 laps.

Here is my 2:08.08 in the Black Model 3:

And the 2:08.8 in the Red Model 3, with some 911 Turbo overtaking included: