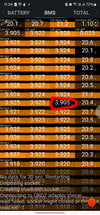

I've directly sourced data on nearly 50 vehicles where third parties have attempted module swaps to fix Model S's, and data from a... source... on an additional ~110. The long term success rate of those is exactly as expected: 0%. There was a contender for a little while that kept that number at about 0.6% success, and I was pulling for it... but it was clearly trending towards failure from day 1 and eventually failed after 9 months of light use (about 4000 miles over 9 months). Oh, and that was

my own best effort at module matching knowing everything I know about the BMS and what it expects.

"You did a module swap? OMG!" Yes, of course I've tried all sorts of ways to do module swaps over the years (not on customer vehicles, of course).... being able to

actually swap modules for repairs would be tons of profit in repairs. But it's sadly not possible. Even Tesla attempted this with early refurb packs and couldn't make it work.

That leaves two and only two correct ways to repair a pack with a bad module:

- Replace the entire pack with a good pack; or

- Downgrade the pack by removing the bad module(s) and doing the other necessary work to make the pack into a standard configuration with the lower module count.

Those are your only legitimate options for a long term repair. This is what Tesla does, and to the best of my knowledge what

@Recell does as well. No one with any sense is mixing modules. And sadly, the complexity of the latter option puts it outside the reach of a DIY project anyway.

There's also a lot more to getting the pack ready for re-use after doing an internal change than just using the correct sealant. The correct sealant isn't going to do you any good if you seal moisture inside, damage an o-ring on a coolant line, leave any debris in the pack, or any of dozens of other ways a problem could be caused. Opening and reusing the top cover of a pack is more of an art, too. You definitely don't want to be relying solely on sealant vs a tight fit. There's also o-rings around some of the bolts that tend to get damaged during removal/install that need inspection/replacement, tons of seals and pieces that tend to get pinched and useless when re-closing a pack if you don't know what you're doing, etc etc etc. Far too extensive of a list to realistically get into.

Suffice it to say there's no DIYer that's going to catch and mitigate all of the potential issues. Even Tesla fails at some of the edge cases in their refurbished packs occasionally, especially anything done at the service center level. I'm not perfect either, and have had to do a couple of redos over the years.