Hey everyone, I just built my own plug and play 4-pin trailer harness for my 2018 Model 3. This is great because it is removable and requires no modification to the factory wiring harness. It can literally be installed in 5 minutes once the harness is complete.

I cannot confirm this will work with every year/demographic Model 3. Mine is a USA Sept 2018 build, vin 114,xxx.

Now, I am not an electrician or a wiring expert (experts will likely laugh at my schematic). I just built something that works for me and thought id share to help others out. You’ll need some mechanical know how as this will not be step by step instructions. Copy my project at your own risk

Difficulty: 3/5

Cost: $65

Time: this can vary but it took me 6 hours (4 of which were me scratching my head wondering if I had the connectors orientated correctly)

Supplies (broken down by location purchased from):

Amazon:

Tools:

Watch this video to get an idea of how the connectors and pins are assembled. This is a different brand and model but they go together the same way. I was able to get by with my standard electrical pliers and not a crimping tool, this took some very careful hands and I gave each with a good tug to make sure they were crimped well enough.

<iframe width="560" height="315" src="

" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

or this one from the manufacturer

<iframe width="560" height="315" src="

" frameborder="0" allow="accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

Here are the photos from the project.

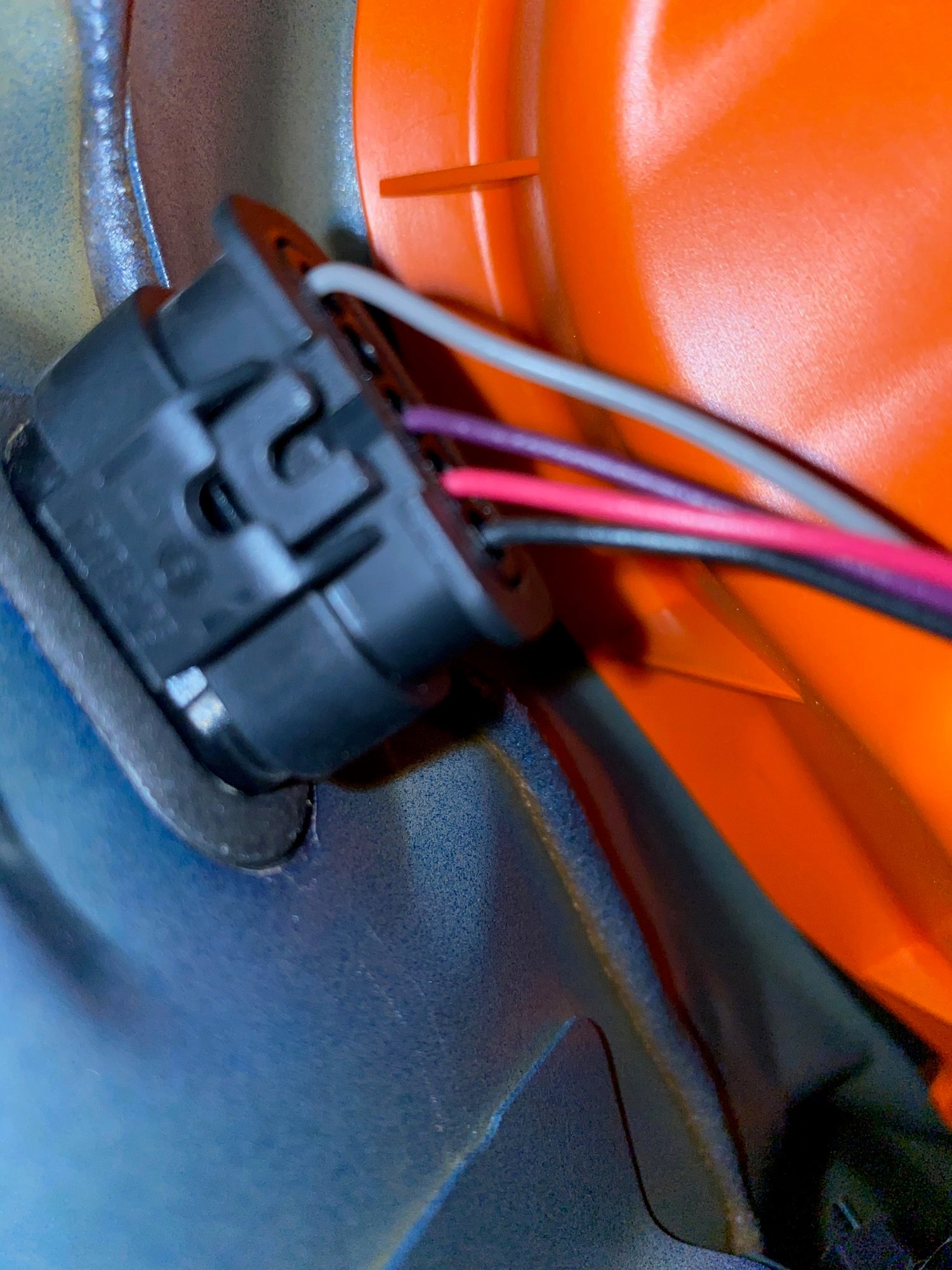

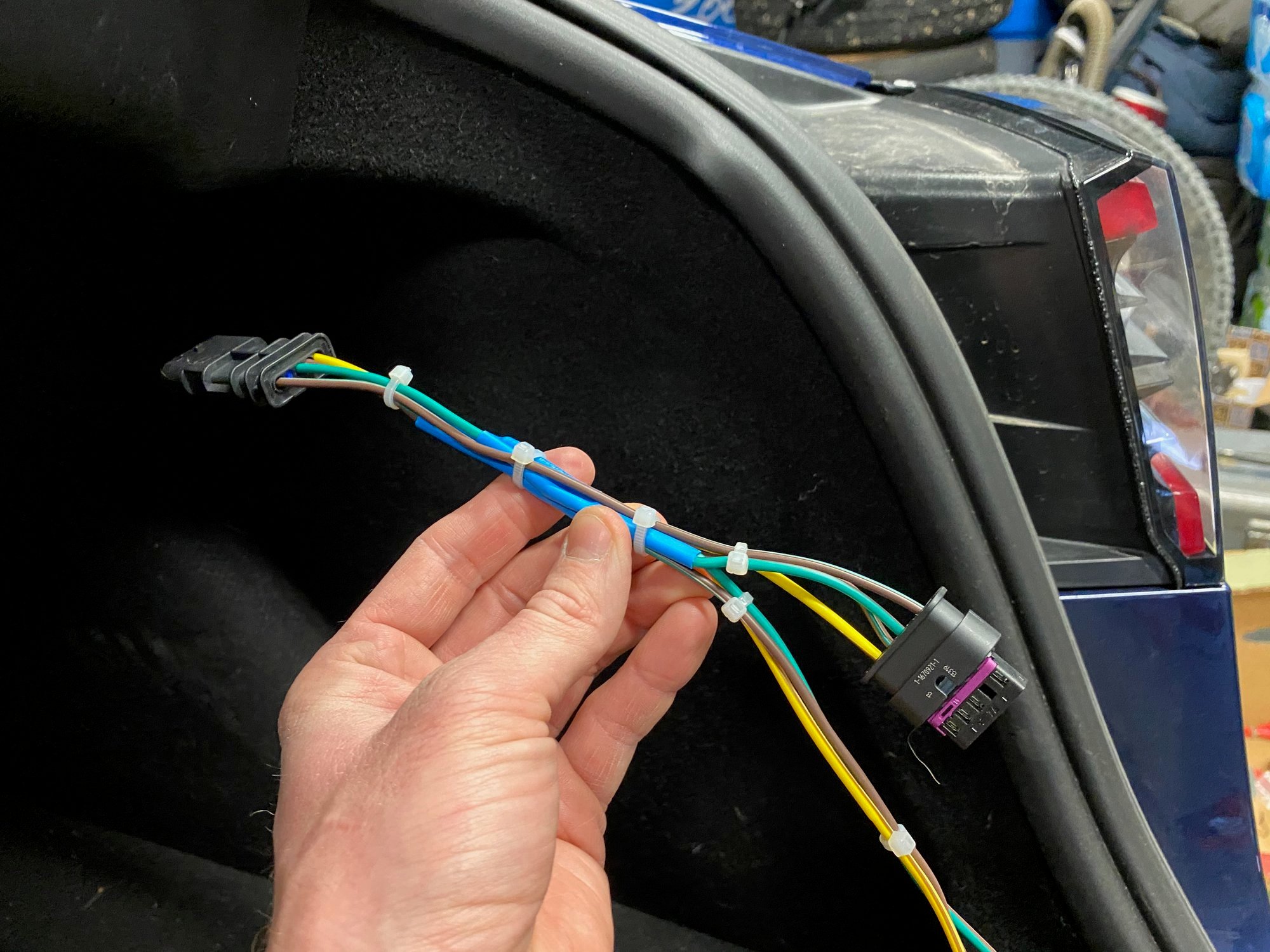

Left side factory harness to tail lamp, here you can see its a 5 plug connector, but only 4 are used, take note of which ones are where! I used the clip seen in the photos below to keep the orientation of the plug towards me during the whole process as the pin locations are not numbered well. Use a paint pen or 'your wifes' nail polish to mark them so you don't get the plug turned around and wired backwards.

Right side factory harness to tail lamp. Same here; one unused socket. Keep this clip mechanism on you're harness facing you during the assembly of your harness so you don't lose orientation.

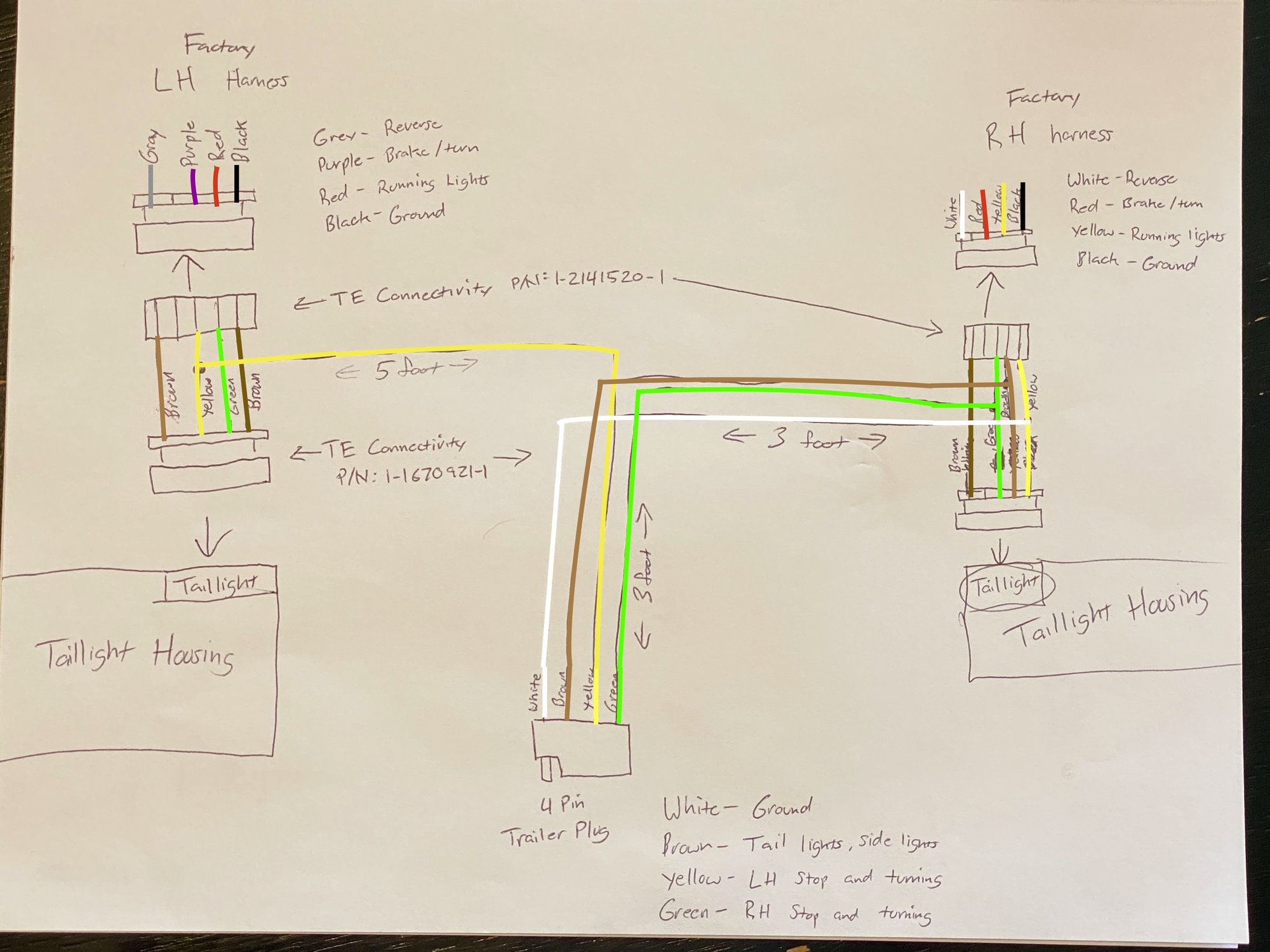

My schematic, yea yea go ahead and laugh, but IT WORKED!

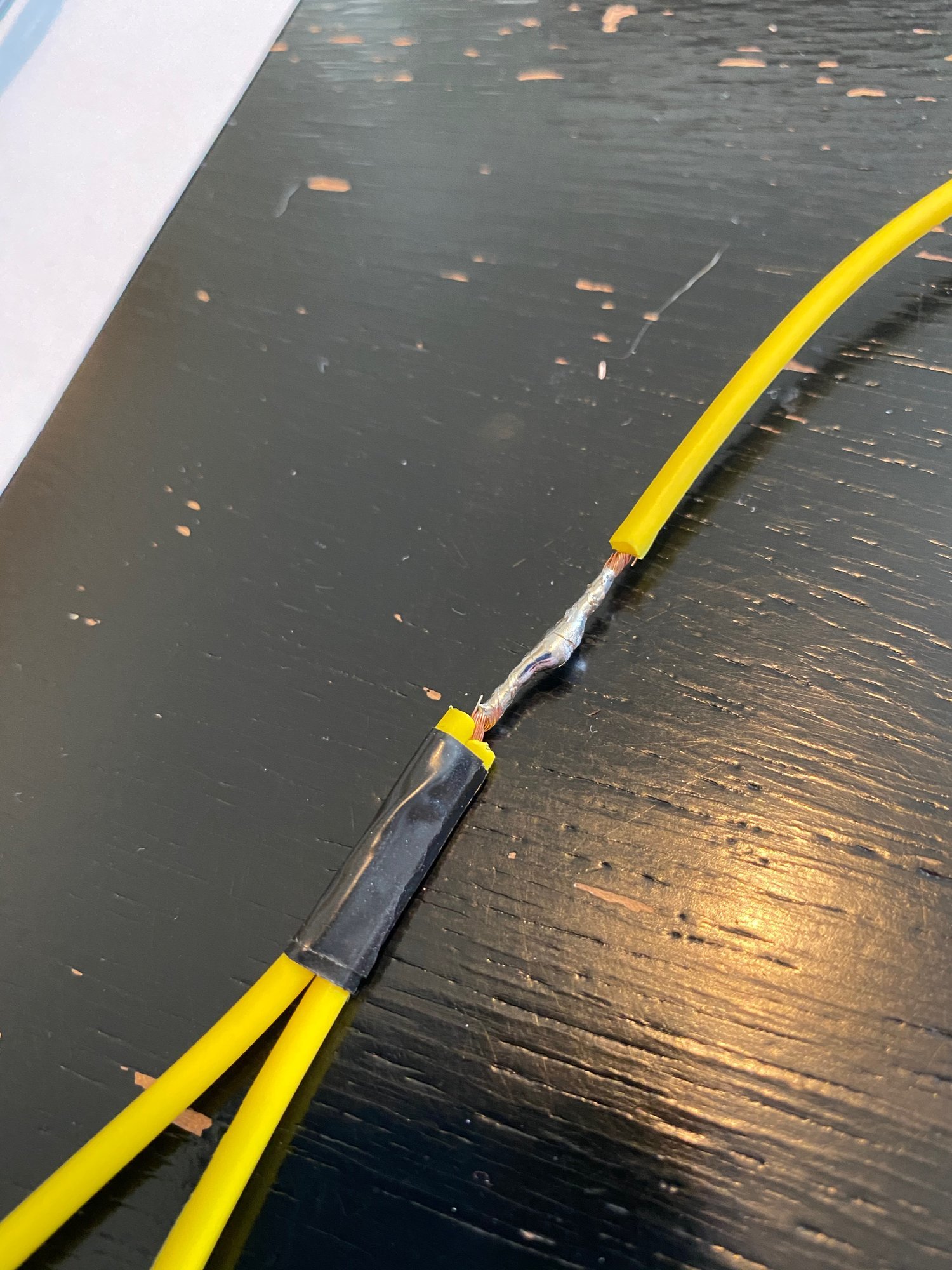

My incredible soldering skills

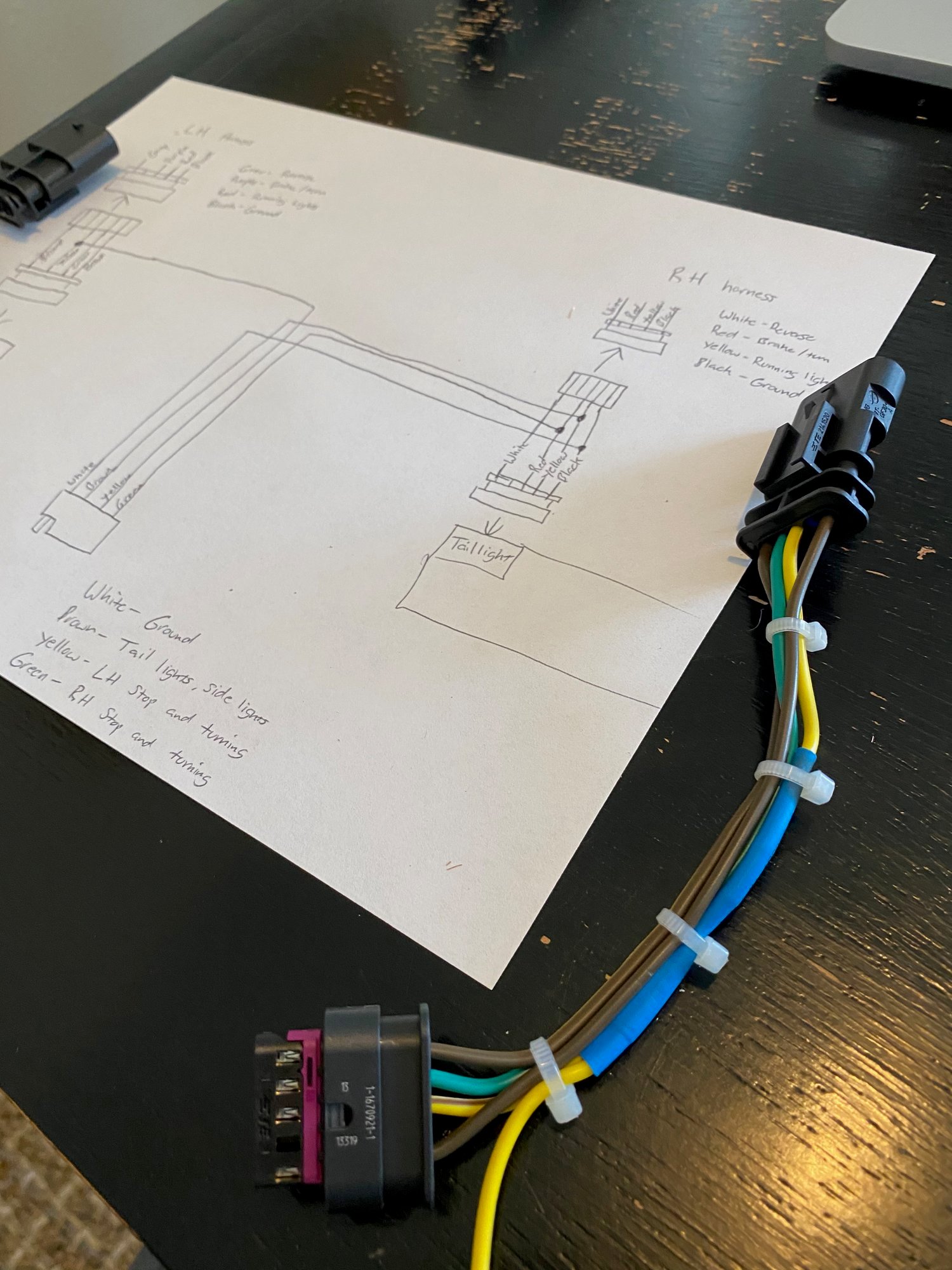

Left side complete! The pins are a little confusing to get in the first time, but look closely at the pins and you'll see they have a little lock mechanism built into them on one of the 4 sides, if you face that mechanism toward the purple side of the connector you'll find they snap in very easily. for the female connector, once all four are in snap the purple lock to the left to lock them into place. The male connector didn't have this slide lock.

Right side complete!

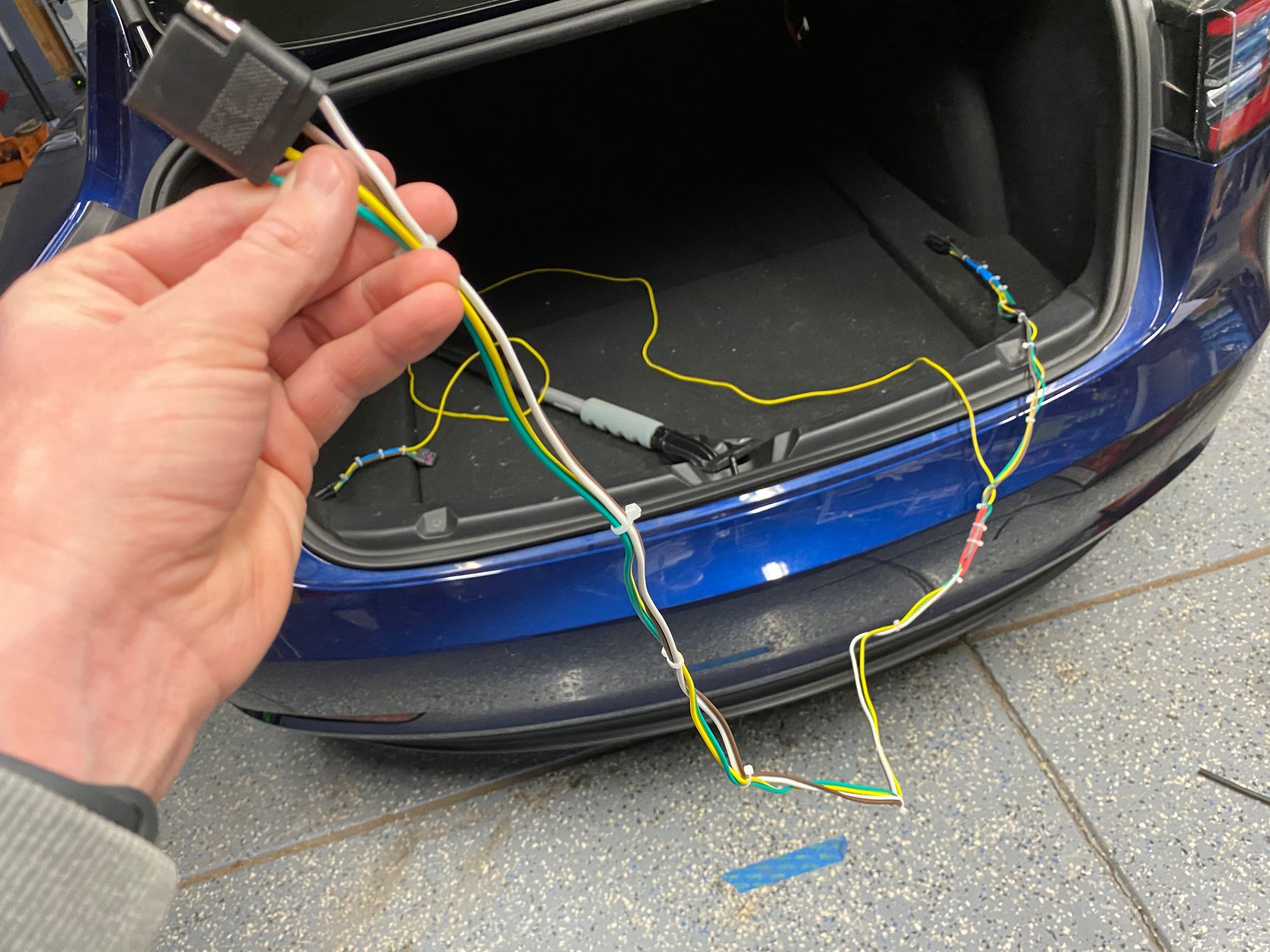

Full harness

Now just need to snap the harness in and tuck all the wires behind the plastic and fabric panels inside the trunk.

All done!

ALL DONE!

I tested the factory lights on my own, but the next day I plugged into a Buddys trailer and everything worked great!

I'm sure I missed some things, so please ask if you need help and I'll try my best.

I cannot confirm this will work with every year/demographic Model 3. Mine is a USA Sept 2018 build, vin 114,xxx.

Now, I am not an electrician or a wiring expert (experts will likely laugh at my schematic). I just built something that works for me and thought id share to help others out. You’ll need some mechanical know how as this will not be step by step instructions. Copy my project at your own risk

Difficulty: 3/5

Cost: $65

Time: this can vary but it took me 6 hours (4 of which were me scratching my head wondering if I had the connectors orientated correctly)

Supplies (broken down by location purchased from):

Amazon:

- 4 pin wiring harness off amazon with tons of extra 18 gauge wire https://www.amazon.com/gp/product/B07JMZNQ7Z/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

- TE Connectivity connector P/N 1-1670921-1 (Quantity Required: 2, but order 3 incase of mistakes)

- TE Connectivity connector P/N 1-2141520-1 (Quantity Required: 2, but order 3 incase of mistakes)

- TE Connectivity female pin P/N 7-1452668-1 (Quantity Required: 8, but order AT LEAST 12 for the first few you’ll break

)

- TE Connectivity male pin P/N 1718760-1 (Quantity Required: 8, but order AT LEAST 12 for the first few you’ll break)

- (Optional) TE Connectivity cavity plug P/N 967056-1 (Quantity: 4 if used)

- (Optional) TE Connectivity wire seal P/N 967067-1 (Quantity: 16 if used) -I found these very difficult to install into the connectors and given this harness will be inside the trunk and not in need of waterproofing, I decided not to use them.

- Solder

- Wire heat shrink

Tools:

- Decent set of electrical pliers (for stripping wire/crimping pins to wire)

- Soldering iron (creating ‘Y” splice)

- Heat gun/lighter (shrinking heat shrink over Y splice)

- Razor blade (used to cut 1/2” exposed section of wire to create Y splice)

Watch this video to get an idea of how the connectors and pins are assembled. This is a different brand and model but they go together the same way. I was able to get by with my standard electrical pliers and not a crimping tool, this took some very careful hands and I gave each with a good tug to make sure they were crimped well enough.

<iframe width="560" height="315" src="

or this one from the manufacturer

<iframe width="560" height="315" src="

Here are the photos from the project.

Left side factory harness to tail lamp, here you can see its a 5 plug connector, but only 4 are used, take note of which ones are where! I used the clip seen in the photos below to keep the orientation of the plug towards me during the whole process as the pin locations are not numbered well. Use a paint pen or 'your wifes' nail polish to mark them so you don't get the plug turned around and wired backwards.

Right side factory harness to tail lamp. Same here; one unused socket. Keep this clip mechanism on you're harness facing you during the assembly of your harness so you don't lose orientation.

My schematic, yea yea go ahead and laugh, but IT WORKED!

My incredible soldering skills

Left side complete! The pins are a little confusing to get in the first time, but look closely at the pins and you'll see they have a little lock mechanism built into them on one of the 4 sides, if you face that mechanism toward the purple side of the connector you'll find they snap in very easily. for the female connector, once all four are in snap the purple lock to the left to lock them into place. The male connector didn't have this slide lock.

Right side complete!

Full harness

Now just need to snap the harness in and tuck all the wires behind the plastic and fabric panels inside the trunk.

All done!

ALL DONE!

I tested the factory lights on my own, but the next day I plugged into a Buddys trailer and everything worked great!

I'm sure I missed some things, so please ask if you need help and I'll try my best.