Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SpaceX ramps up operations in South Texas as Hopper tests loom:

SpaceX ramps up operations in South Texas as Hopper tests loom – NASASpaceFlight.com

"Pending any technical difficulties or interruptions, SpaceX will attempt an untethered hop test with a target altitude of 20 meters early next month."

SpaceX ramps up operations in South Texas as Hopper tests loom – NASASpaceFlight.com

"Pending any technical difficulties or interruptions, SpaceX will attempt an untethered hop test with a target altitude of 20 meters early next month."

What’s most interesting about that (to me anyway...) is that they’re using a very imprecise machine (the telescoping forklift) to do what is traditionally a very precise operation (bolting space stuff together). Traditionally an operation like this would have a specific piece (or set) of GSE that would cost hundreds of thousands in capex, including hundreds of hours to design/fab...and the whole deal would be performed in a very controlled environment.

It might seem trivial, but this kind of approach is really where SpaceX sets itself apart from the rest of the industry.

It might seem trivial, but this kind of approach is really where SpaceX sets itself apart from the rest of the industry.

What’s most interesting about that (to me anyway...) is that they’re using a very imprecise machine (the telescoping forklift) to do what is traditionally a very precise operation (bolting space stuff together). Traditionally an operation like this would have a specific piece (or set) of GSE that would cost hundreds of thousands in capex, including hundreds of hours to design/fab...and the whole deal would be performed in a very controlled environment.

It might seem trivial, but this kind of approach is really where SpaceX sets itself apart from the rest of the industry.

I had the same though regarding equipment. On the other hand, the engine attachment is via the positioning actuators and struts, so it is not a high precision operation like aligning two hard mount surfaces or installing a bearing.

I have zero aerospace industry background, but I had the same basic reaction to that image. What SpaceX is doing at Boca Chica, out in the open, just blows my mind. Of course this unconventional approach has yet to prove itself. But if it proves successful it will upend the rocket construction paradigm.

What’s most interesting about that (to me anyway...) is that they’re using a very imprecise machine (the telescoping forklift) to do what is traditionally a very precise operation (bolting space stuff together). Traditionally an operation like this would have a specific piece (or set) of GSE that would cost hundreds of thousands in capex, including hundreds of hours to design/fab...and the whole deal would be performed in a very controlled environment.

It might seem trivial, but this kind of approach is really where SpaceX sets itself apart from the rest of the industry.

I had the same though regarding equipment. On the other hand, the engine attachment is via the positioning actuators and struts, so it is not a high precision operation like aligning two hard mount surfaces or installing a bearing.

Interesting. I would have just assumed the actuators and struts would have gone to a mounting plate, but it does make sense that you could just use them for the ‘precision’ part of the installation operation. Then any small misalignments could be calibrated out by some script that finds the new/real nominal zero point for the motor.

Interesting. I would have just assumed the actuators and struts would have gone to a mounting plate, but it does make sense that you could just use them for the ‘precision’ part of the installation operation. Then any small misalignments could be calibrated out by some script that finds the new/real nominal zero point for the motor.

I think you are right. I missed it the first time, but there appear to be black struts running upward from the same bracket the white shipping struts are connected to. Given the lack of clearance, the pivot portion may be on hopper already, so it is just plate to plate. That makes the motor common between fixed and maneuverable installations also.

They probably dial in the zero angle after mounting to remove all the tolerances. The flight system should back out any offsets also.

Those white struts are just transport equipment for securing the load in place, I also think that 'the black struts' are the actual actuators. (Electric ones I guess)

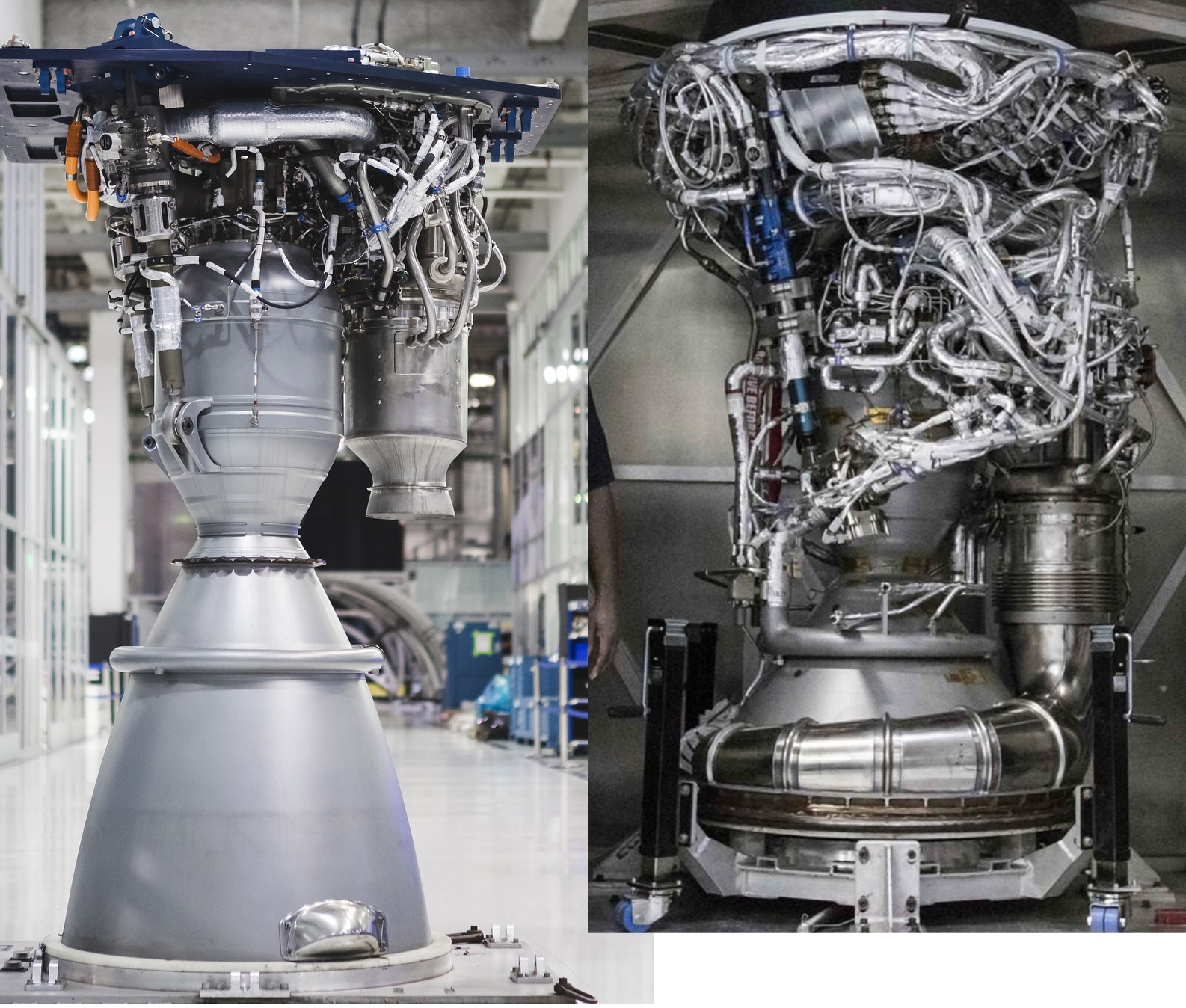

View attachment 414708

View attachment 414713

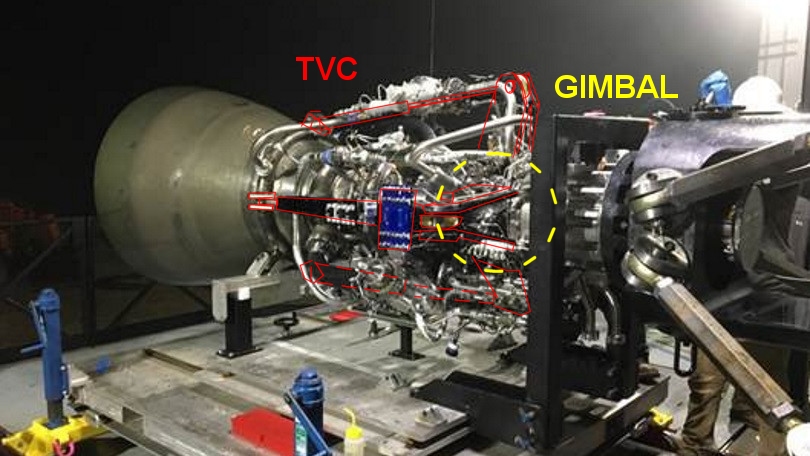

View attachment 414715

Nice pics!

Given the lack of space around the black struts, tight clevis, and lack of bends in the piping to the bell, I think the entire engine gimbals and those black struts are fixed.

The main load path seems to be right up the centerline to the test stand through the structure seen in this pic:

I think the tapered pipes at the attach end are the LOX and CH4 connections.

Given the lack of space around the black struts, tight clevis, and lack of bends in the piping to the bell, I think the entire engine gimbals and those black struts are fixed.

Yeah, you wouldn’t want to gimbal across any of the charged pressure lines if you could help it, let alone between the chamber and the bell—it’s far less complex to gimbal the relatively low pressure feeder lines from the tanks.

Just googsed this (obviously, it’s not a raptor):

That's a Falcon 1's thrust vectoring system. Falcon 9's TVC(s) are build lot tighter:

I read somewhere that: LOX line goes through the gimbal and methane (in) and tank pressurization (out) lines are (more) flexible:

Turbo pumps prepurners and all other high pressure stuff moves with the engine (LOX turbopump and prepurner are in same block as the combustion chamber...)

I read somewhere that: LOX line goes through the gimbal and methane (in) and tank pressurization (out) lines are (more) flexible:

Turbo pumps prepurners and all other high pressure stuff moves with the engine (LOX turbopump and prepurner are in same block as the combustion chamber...)

Last edited:

That's a Falcon 1's thrust vectoring system. Falcon 9's TVC(s) are build lot tighter:

View attachment 414769

I read somewhere that: LOX line goes through the gimbal and methane (in) and tank pressurization (out) lines are (more) flexible:

View attachment 414770

Gotcha, so the actuators react from the mount to the bell and the gimbal is integral to the Raptor? The clevis has more room than I gave it credit for.

I saw a pic that showed O2 flow down the center, but it looked like the drawing was missing the gimbal section. It would make sense to flex the cryo line as little as possible.

"For instance, up until recently, the company was planning to utilize Raptor SN4 for the untethered hops. However, the company has now decided to utilize this engine only for fit checks, and will instead perform the hops with SN5 – the latest Raptor to come out of SpaceX’s factory in Hawthorne, California... While the precise reason for the engine change is unknown..."

SpaceX readying Starhopper for hops in Texas as Pad 39A plans materialize in Florida – NASASpaceFlight.com

Is it good idea lift it with forklift after all? (someone in NSF claims to see dent at SN4's bell, but who knows. It can be just hand-marks like before, and article reads like that SpX already know before transport that SN4 will not be used for hops)

SpaceX readying Starhopper for hops in Texas as Pad 39A plans materialize in Florida – NASASpaceFlight.com

Is it good idea lift it with forklift after all? (someone in NSF claims to see dent at SN4's bell, but who knows. It can be just hand-marks like before, and article reads like that SpX already know before transport that SN4 will not be used for hops)

Last edited:

Yeah, just watching those Merlin 1D pictures, is it hard to believe that there is enough clearance for movement. Also which pipes move with engine block and which flex in M1Dvac pic?

And there is lot more going on with Raptor and its test equipment...

On the up side, like @bxr140 mentioned, the inlets are not highly pressurized. 50-100 psi liquid is much easier to seal and make couplings for than 2,000 psi gas.

Is it good idea lift it with forklift after all? (someone in NSF claims to see dent at SN4's bell, but who knows)

It looks like the white struts are supporting it off the pallet. Dent may be unrelated to telehandler.

JRP3

Hyperactive Member

Ever see those precision equipment demonstrations where they open a beer bottle with a backhoe? I think a good operator can be very precise.

Similar threads

- Replies

- 667

- Views

- 29K

- Replies

- 9

- Views

- 4K