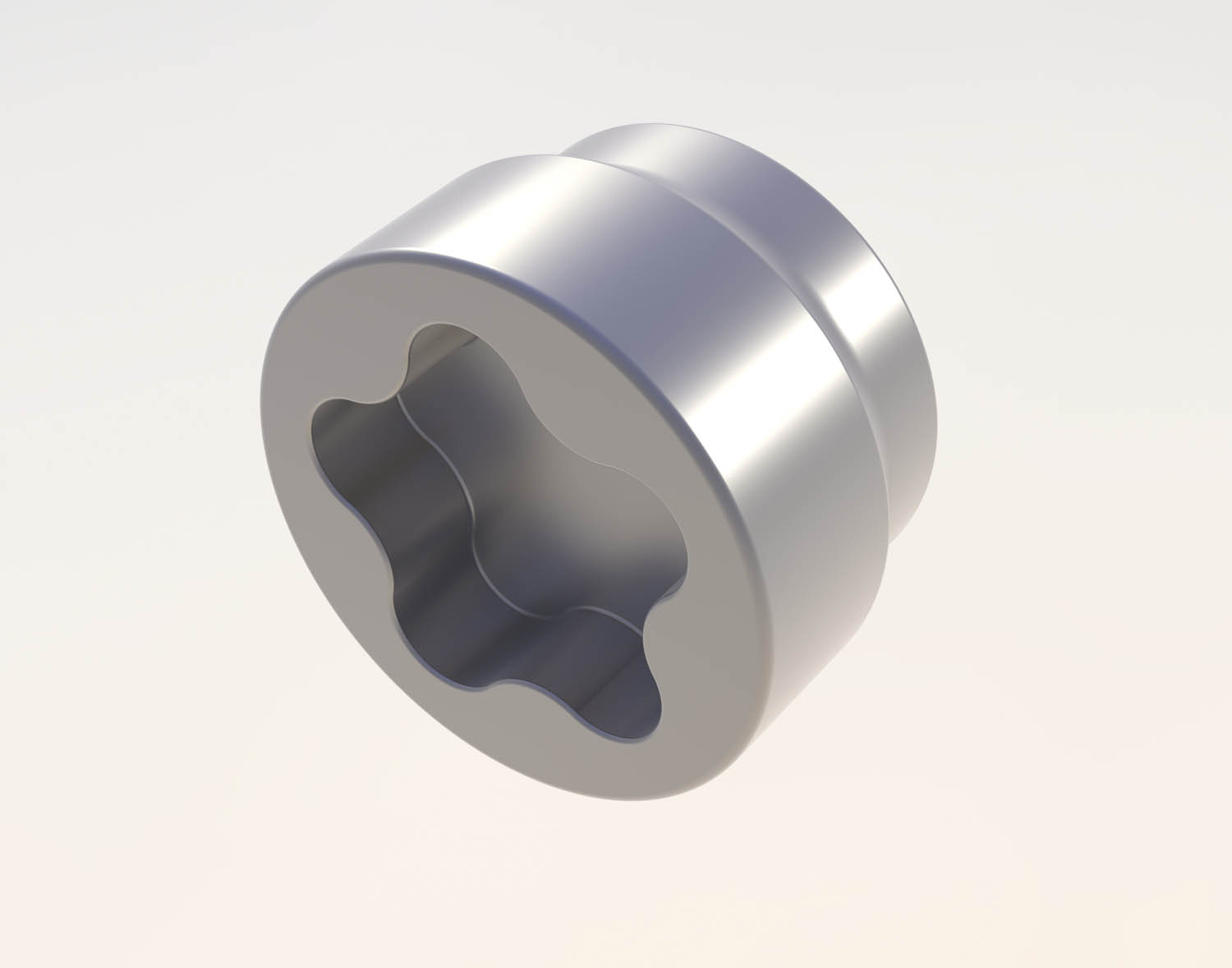

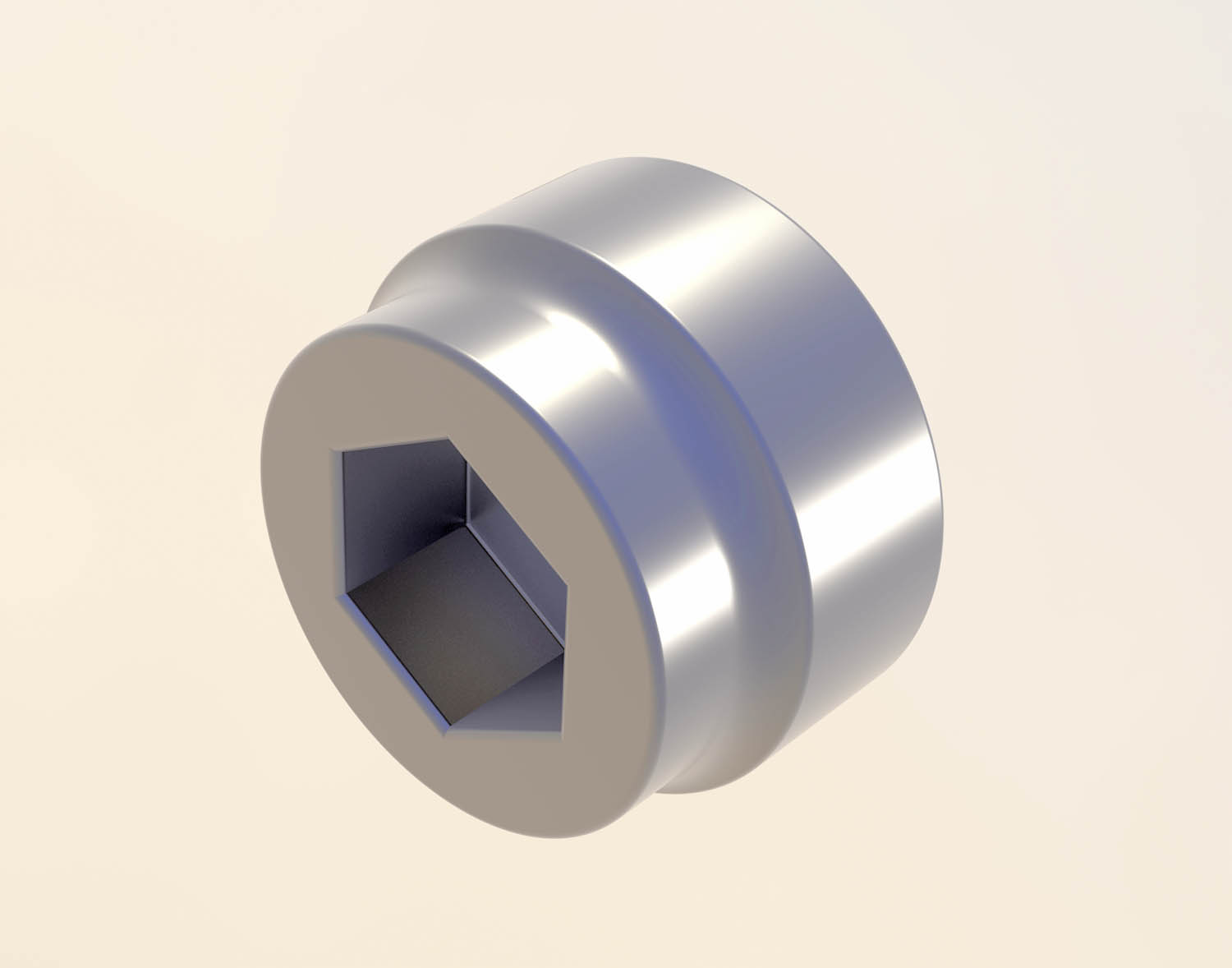

So, thanks to Btrflyl8e who was gracious enough to send me a sample screw, I've designed simple little socket adapter that will remove these screws. The socket design has a recess for the wacko 5-lobed security screw and a 1/4 inch recess on the other side that will fit onto a 1/4 inch drive ratchet or Allen wrench or nut driver. I tried to keep it small, simple and affordable.

It's currently being 3D printed by Shapeways.com out of stainless steel. I'm getting one in about a week or test and if it passes muster I'll offer it up for sale on Shapeways. Not looking to really make a profit on this. I just want to provide a service to the community. And because I think these screws are stupid. I will keep everyone posted.

-Jim

It's currently being 3D printed by Shapeways.com out of stainless steel. I'm getting one in about a week or test and if it passes muster I'll offer it up for sale on Shapeways. Not looking to really make a profit on this. I just want to provide a service to the community. And because I think these screws are stupid. I will keep everyone posted.

-Jim