Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ear pain/Pressure help

- Thread starter justobuf

- Start date

-

- Tags

- sound proofing

I did remove the wheel well covers on the outside of the car and applied butyl and acoustic foam. I cut sections of butyl to fit the flat areas then covered everything with the foam sheets. Then I worked to get the wheel well coverings back in place. I don't have any decibel measurements, but I believe it helped and certainly didn't hurt.

MyEarHurts

Banned

Yeah I did all that too but doubled/trippled the butyl then the foam, no difference for the boominess/ear pressure but some "slight" road noise removal. For another Y I also sprayed the rear wheel well with that tar like material like an undercoating but it's meant for sound absorbtion with no difference.

WADan

Member

Sound proofing is really difficult. I have two heatpumps, and the bigger one has a soundproofing blanket around the compressor (installed by contractor) and it does a really good job of reducing the noise. The small one did not have the blanket, and one of my neighbors complained that it’s too noisy at night (almost 70 decibels as measured by my iphone). I tried wrapping it with two layers of butyl, and it reduced it by only 5 decibels. Finally I bought a soundproof blanket (from Amazon) and it reduced it by another 5. The noise is now down to acceptable level (high 40 decibels). But wrapping around the compressor is easy, not like trying to soundproof the car with all the barriers getting in the way.

Yup. Did that too. I guess it helped some. It is no longer a loud drum when I tap on it. Like @MyEarHurts said, this is all about road noise and not the booming. I'm lucky to not have that issue. My road noise is not loud either. I just like to play around with this stuff.Has anyone insulated the top of the rear belly pan? It's yet another possible source of boominess...when I thump on it, it's quite loud.

The large subtrunk is one of the first areas I coated in butyl. I think that did nothing.Has anyone insulated the top of the rear belly pan? It's yet another possible source of boominess...when I thump on it, it's quite loud.

IMO, step 1 is rigid stops, step 2 is butyl + foam on the rear wheelwells.

MyEarHurts

Banned

Butyl on the trunk bin like above won't do anything unfortunately as I did it as well with double layers, I tapped on it and it resonated so I assumed it would help but it didn't. As for putting butyl in the wheel wells (rear) I would just triple up on the layers on the inside vs the outside just in case moisture gets trapped in and cause rust (if possible) or anything like that. I put as much as I could around the areas where the struts mount. With all this work the road noise is minimized but the boominess is mainly reduced from the hatch stops using pvc endcaps.

I didn't notice that anything is wrong with acoustic comfort in my car until I found this thread and then started hearing this in my car. The worst thing is that I can't "unhear" it anymore. I wish I would never see this topic in this forum

Do you guys know if Model X have the same acoustic "booming" problem?

Do you guys know if Model X have the same acoustic "booming" problem?

The rear of my car has developed a school bus-like squeaky rattle of any imperfection in the road. I haven't had anyone ride in the back and report where it's coming from. I'm assuming it's from removing the rear inner panels over the wheel wells. I know I lost one clip when putting it all back together. Makes me regret doing butyl/insulation work back there. I didn't get a benefit from it.

On some roads, that new noise combined with the general high level of road noise makes having a Bluetooth phone call difficult. It's almost embarrassing.

On some roads, that new noise combined with the general high level of road noise makes having a Bluetooth phone call difficult. It's almost embarrassing.

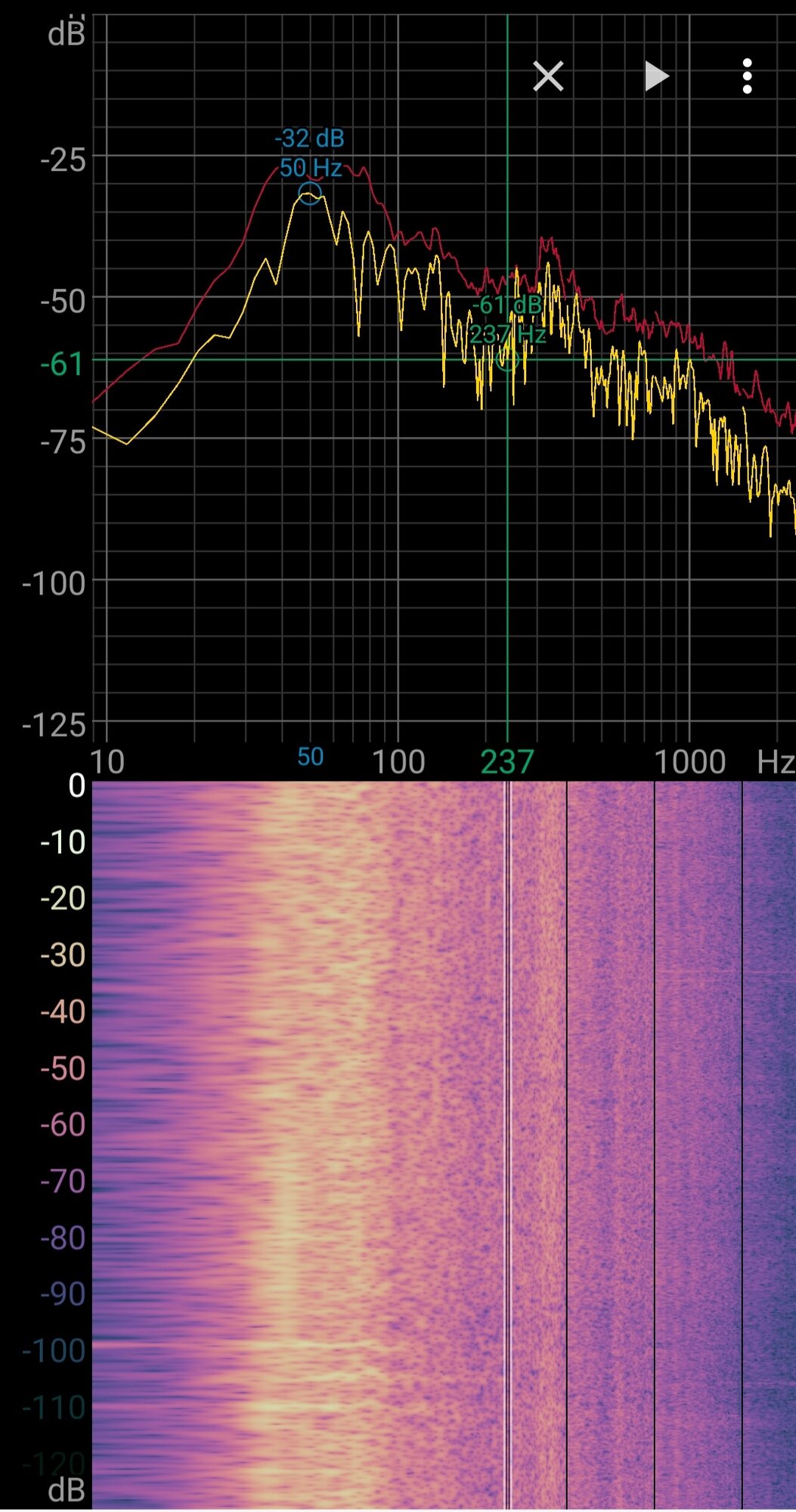

I with my 255/50r19 tires aired down to 38 PSI and the work I've done to quiet the car, I was just noticing how pleasant my cabin is now. Here's a graph at 65 MPH. Soooo much improved. No spike at 41 Hz high frequency way down...

I just took off the right panel. Same as left but I had to remove the amplifier to get to the 3 subwoofer screws. You will need to pop out the panel near the C pillar too. Use 10mm nut wrench. Hope this helps.Today the weather was in the low 50s (in order for the glue of butyl to stick well per instruction), so I tried to do the surgery.

A couple of questions if you have the same situation:

(*j. I was only able to put the insulation on the top part of the left wheel well to the rear, and not on the side (next to the vertical panel) as there is no clearance.

(*) On the right side, the woofer box gets in the way, and I didn’t try to remove it so there is only a short part of the exposed wheel well that I can put some insulation on.

I did have some noise measurements (using my iphone) before the surgery, so I will try to measure the noise again tomorrow on the same roads. Thanks!

Attachments

stolatl

Member

OMG... didn't know about this issue at all until we took delivery of our Y two days ago. Coming from a 2017 Model 3 that had been perfect to the moment we traded it in, we didn't expect any issues with the Y. Unfortunately, I didn't notice the booming sound issue at the delivery appointment until the next morning when I went to work. It's like every single road crack would cause a boom around my head.

I haven't felt the wind buffeting effect yet and not sure if it's same thing as the booming issue. Spent the whole night yesterday reading through this mega thread. Looks like I should start with the vinyl tube hack and the rigid cap hack ilovecoffee and MY-Y suggested.

Before that, I have something I'd like to check with the group here. My truck lift gate appears to be misaligned. The first two photos below are from the driver side and the last two are from the passenger side. Does it look normal to you guys? My local SC is booked all the way to Jan 12 next year. Already scheduled an appointment but wondering if I should try the hacks first or wait until they take a look at the lift gate. Really appreciate any suggestions.

I haven't felt the wind buffeting effect yet and not sure if it's same thing as the booming issue. Spent the whole night yesterday reading through this mega thread. Looks like I should start with the vinyl tube hack and the rigid cap hack ilovecoffee and MY-Y suggested.

Before that, I have something I'd like to check with the group here. My truck lift gate appears to be misaligned. The first two photos below are from the driver side and the last two are from the passenger side. Does it look normal to you guys? My local SC is booked all the way to Jan 12 next year. Already scheduled an appointment but wondering if I should try the hacks first or wait until they take a look at the lift gate. Really appreciate any suggestions.

Attachments

That misalignment could definitely make it worse. You can adjust the hatch stops now (envelope test). I would wait until after the appointment for anything more invasive. They might blame your hacks for any issues. Good luck.OMG... didn't know about this issue at all until we took delivery of our Y two days ago. Coming from a 2017 Model 3 that had been perfect to the moment we traded it in, we didn't expect any issues with the Y. Unfortunately, I didn't notice the booming sound issue at the delivery appointment until the next morning when I went to work. It's like every single road crack would cause a boom around my head.

I haven't felt the wind buffeting effect yet and not sure if it's same thing as the booming issue. Spent the whole night yesterday reading through this mega thread. Looks like I should start with the vinyl tube hack and the rigid cap hack ilovecoffee and MY-Y suggested.

Before that, I have something I'd like to check with the group here. My truck lift gate appears to be misaligned. The first two photos below are from the driver side and the last two are from the passenger side. Does it look normal to you guys? My local SC is booked all the way to Jan 12 next year. Already scheduled an appointment but wondering if I should try the hacks first or wait until they take a look at the lift gate. Really appreciate any suggestions.

stolatl

Member

Thanks Noflash. I tried the envelope test this afternoon. After the hatch stops were appropriately adjusted, that gap in the first photo looked slightly larger. And I even slipped an envelope into the trunk through that gap, which means the rubber seal is not making contact of the trunk at all in that area. Definitely need SC to realign the lift gate then. Called them again and was able to move my appointment to 1/3. Will report back after.That misalignment could definitely make it worse. You can adjust the hatch stops now (envelope test). I would wait until after the appointment for anything more invasive. They might blame your hacks for any issues. Good luck.

Similar threads

- Replies

- 0

- Views

- 166

- Replies

- 3

- Views

- 4K

- Replies

- 2

- Views

- 1K