I have solved the low frequency issue with my car. I had a 41 Hz standing wave that would come and go. It wasn't good. If the hatch bumpers are loose, a crazy subsonic buffeting occurs. I'm talking about the annoying rumble that is still there when the bumpers are properly adjusted.

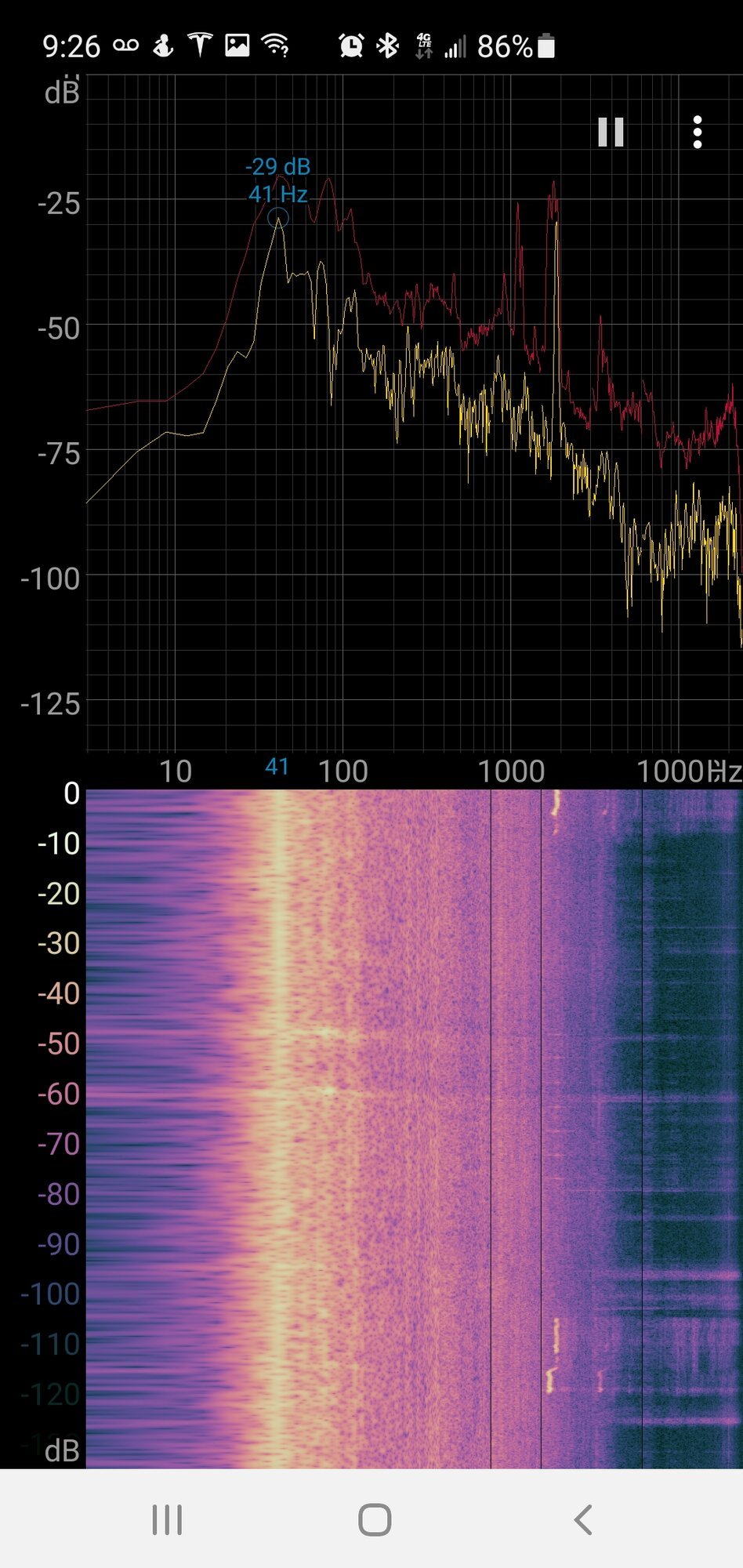

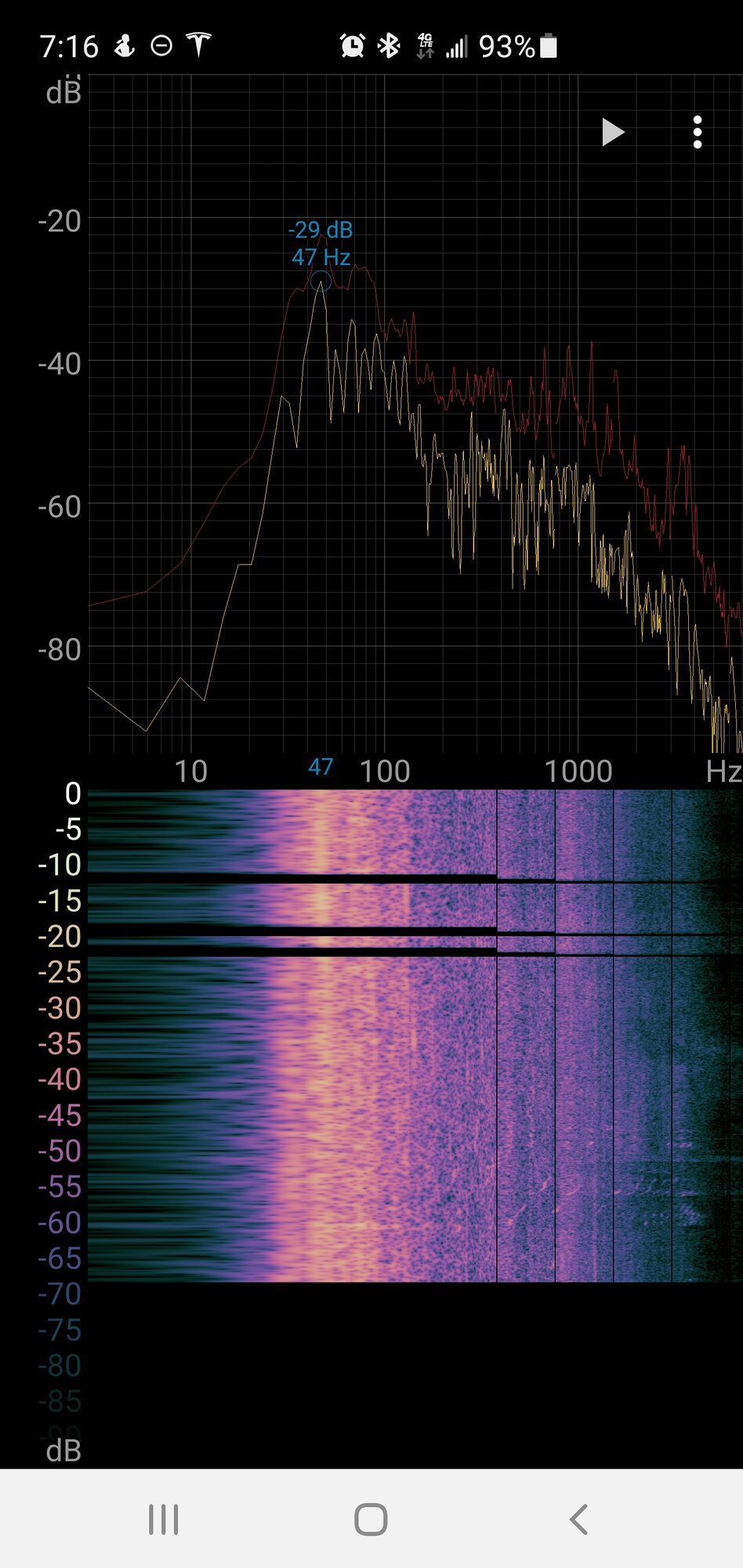

To keep it brief, I placed my phone running the "spectroid" spectrum analyzer on my dash. I then went aound my car, thumping different spots with my hand to see which area(s) caused a 41 Hz resonance. Bottom line, pretty much all of the low frequency is from the hatch. Center glass and center of the metal has resonances at 47 and 50 Hz. The corners where the upper bumpers hit are the 41 Hz culprit.

I made a temporary rigid stop from wood and Epoxy putty to verify that the harmonic could be eliminated, and it can. I then spent a whopping $1.98 on two PVC plumbing pieces, my Epoxy putty, and flat black spray paint for a permanent fix. With the temporary blocks, I knew the exact height needed. I used my sander to shorten the PVC pieces to make the original squishy rubber bumpers ridged at the right length.

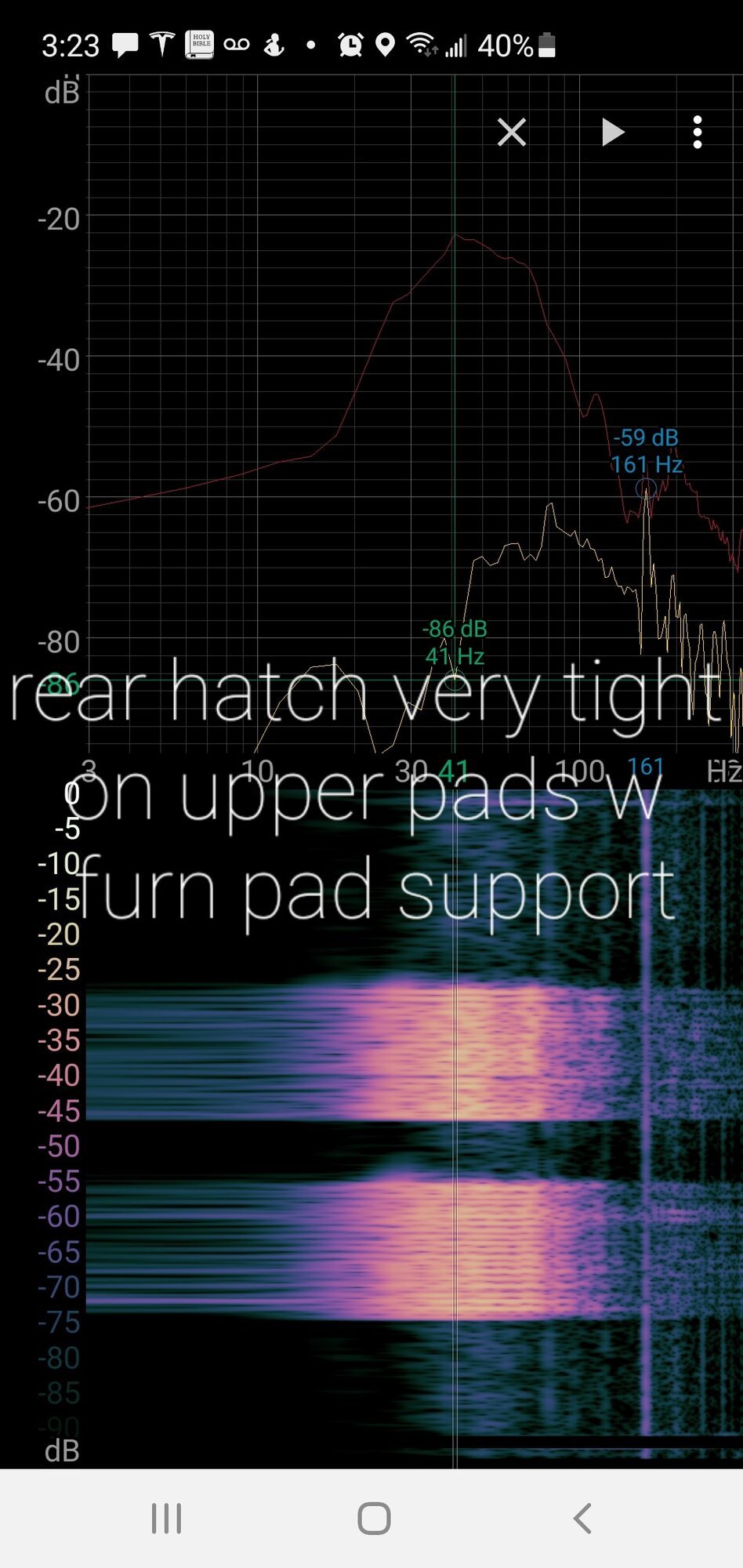

You can see the 41 Hz honor- look at read peak line when I thumped the hatch above where the upper bumpers were mounted.

Making the temporary rigid stops.

Resulting temporary stops.

OEM stops with shortened PVC caps, sanded to same length as wood/Epoxy stops. Note, these are shorter than I had my OEM stops set to. These caps had to be hollowed out a little to fit over the rubber stops. Friction probably would have held them on, but I put a bit of Epoxy putty to hold them to the plastic turn collar just to be sure.

Final product - painted stops are rigid and look OEM. The foam board I'm holding was put inside the hatch above the stops. I don't think this was needed. The bottom stops still need to be adjusted to hit.

Irritating 41 Hz rumble before this fix is shown above.

The 41 Hz is GONE. Every now and then, it is back for a couple of seconds, but 99% of the time, it's gone.

The 47 and 50 Hz sounds are not annoying to me. If I feel inspired, I may make rigid stops for the bottom two.

Bottom line... after careful analysis, I have made my car much more enjoyable for very little cost.

To keep it brief, I placed my phone running the "spectroid" spectrum analyzer on my dash. I then went aound my car, thumping different spots with my hand to see which area(s) caused a 41 Hz resonance. Bottom line, pretty much all of the low frequency is from the hatch. Center glass and center of the metal has resonances at 47 and 50 Hz. The corners where the upper bumpers hit are the 41 Hz culprit.

I made a temporary rigid stop from wood and Epoxy putty to verify that the harmonic could be eliminated, and it can. I then spent a whopping $1.98 on two PVC plumbing pieces, my Epoxy putty, and flat black spray paint for a permanent fix. With the temporary blocks, I knew the exact height needed. I used my sander to shorten the PVC pieces to make the original squishy rubber bumpers ridged at the right length.

You can see the 41 Hz honor- look at read peak line when I thumped the hatch above where the upper bumpers were mounted.

Making the temporary rigid stops.

Resulting temporary stops.

OEM stops with shortened PVC caps, sanded to same length as wood/Epoxy stops. Note, these are shorter than I had my OEM stops set to. These caps had to be hollowed out a little to fit over the rubber stops. Friction probably would have held them on, but I put a bit of Epoxy putty to hold them to the plastic turn collar just to be sure.

Final product - painted stops are rigid and look OEM. The foam board I'm holding was put inside the hatch above the stops. I don't think this was needed. The bottom stops still need to be adjusted to hit.

Irritating 41 Hz rumble before this fix is shown above.

The 41 Hz is GONE. Every now and then, it is back for a couple of seconds, but 99% of the time, it's gone.

The 47 and 50 Hz sounds are not annoying to me. If I feel inspired, I may make rigid stops for the bottom two.

Bottom line... after careful analysis, I have made my car much more enjoyable for very little cost.

Last edited: