I had a busted UMC lying around that I salvaged the cord from for another project.

Left with a useless UMC box, I decided to open it up and take a look around. This particular UMC met its demise by having the cord forcibly pulled out of the UMC box while actively charging.

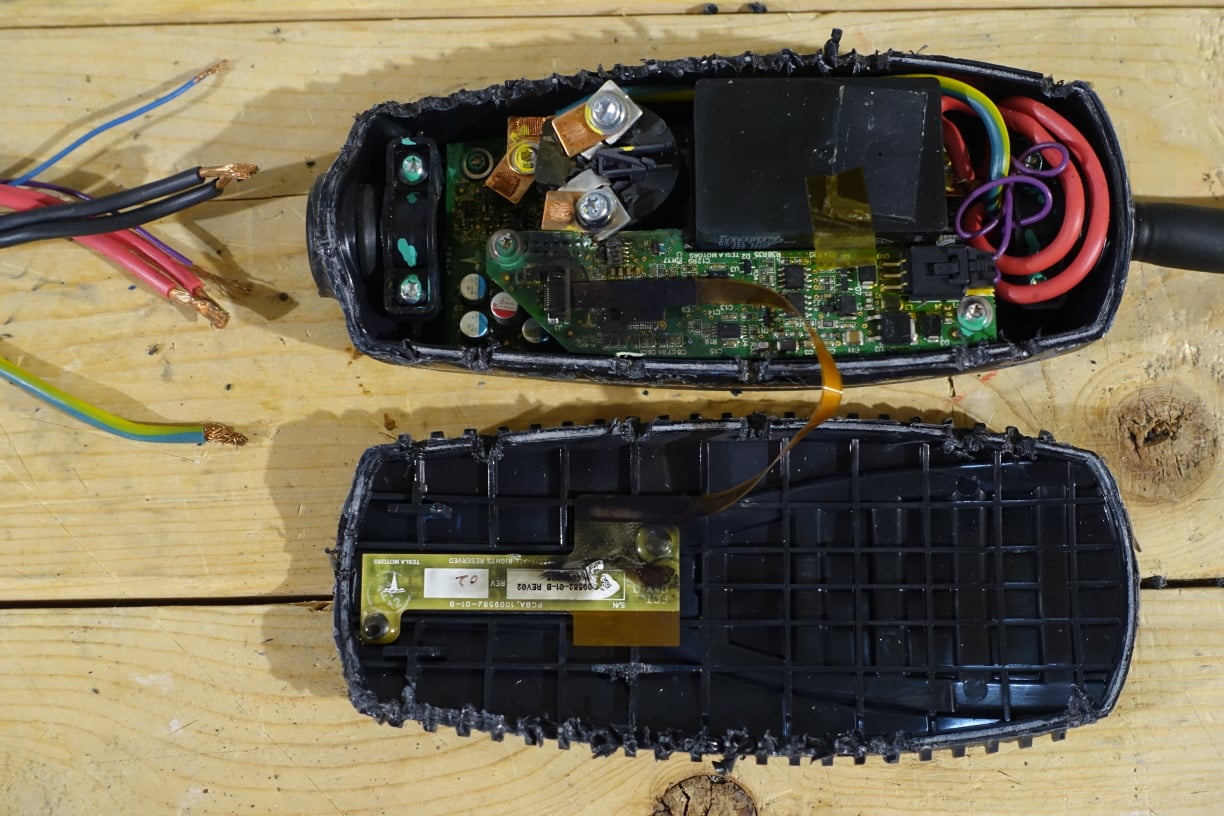

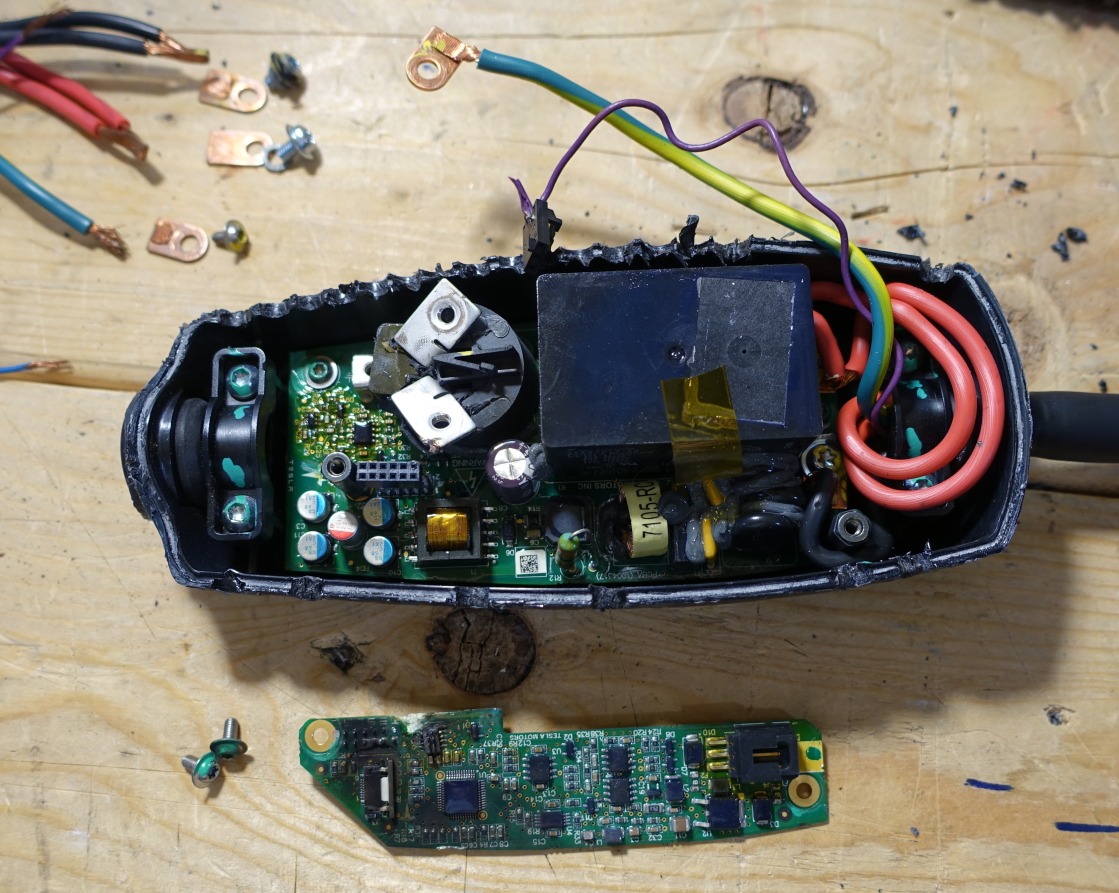

The metal and rubber outer shell was easy enough to get off, however the assembled plastic box appears to have been surrounded by an injected plastic that sealed the inner box in a cover of melted plastic sealing all the gaps and entombing the inner box.

Suffice it to say, the inner top and bottom parts of the plastic box were welded or glued very well, I had to drill out one entire side and then pry around the rest. Luckily the inside was not injected with plastic like others have found in the handle and other parts.

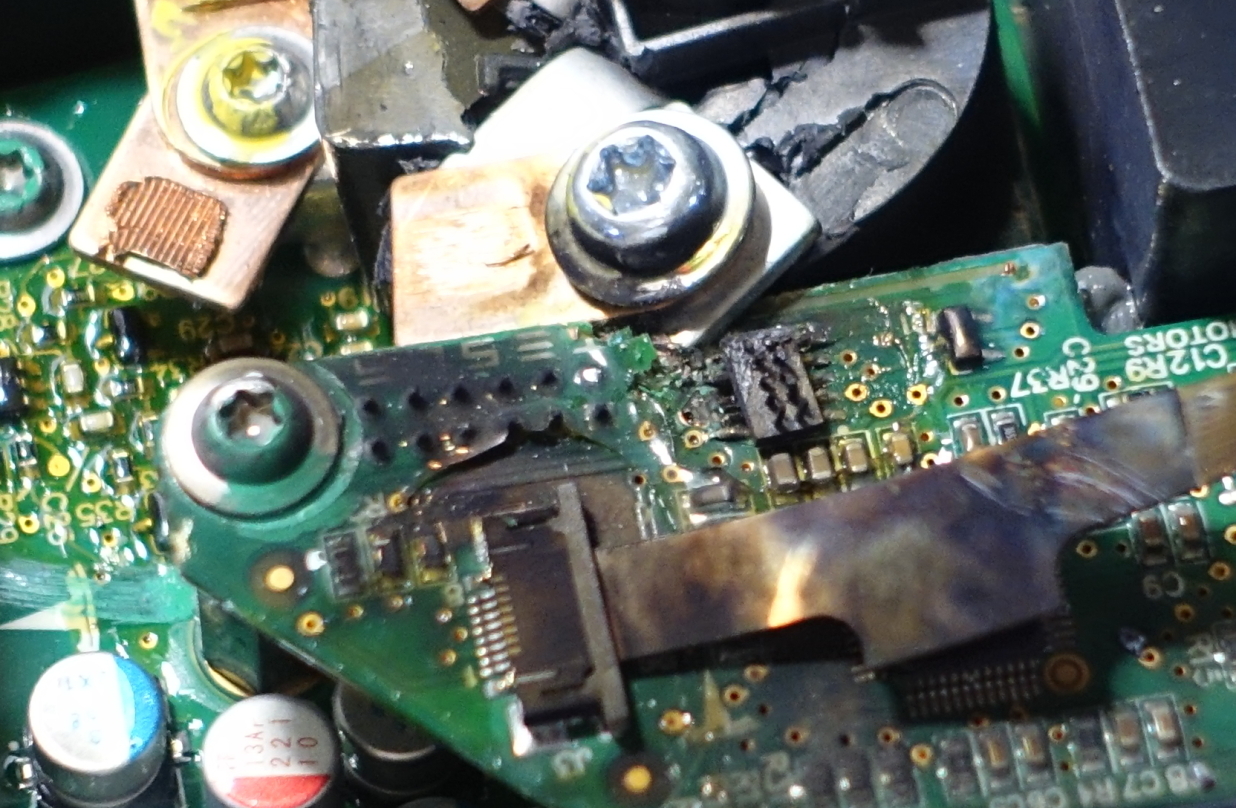

A quick look reveals that as the cord was pulled out it bent the high voltage output connections driving one of them into the logic board where it intersected a ground plane (among other things). The magic smoke was released in the process. Also note (not shown) that in the process, the plastic around one of the pins inside the box-wall cable to NEMA interconnection melted slightly, undoubitly due to the ground short inside the UMC box.

All of the AC wires (and ground) are crimped onto copper plates before screwing into the power board. Makes a good connection but it was also the point of failure.

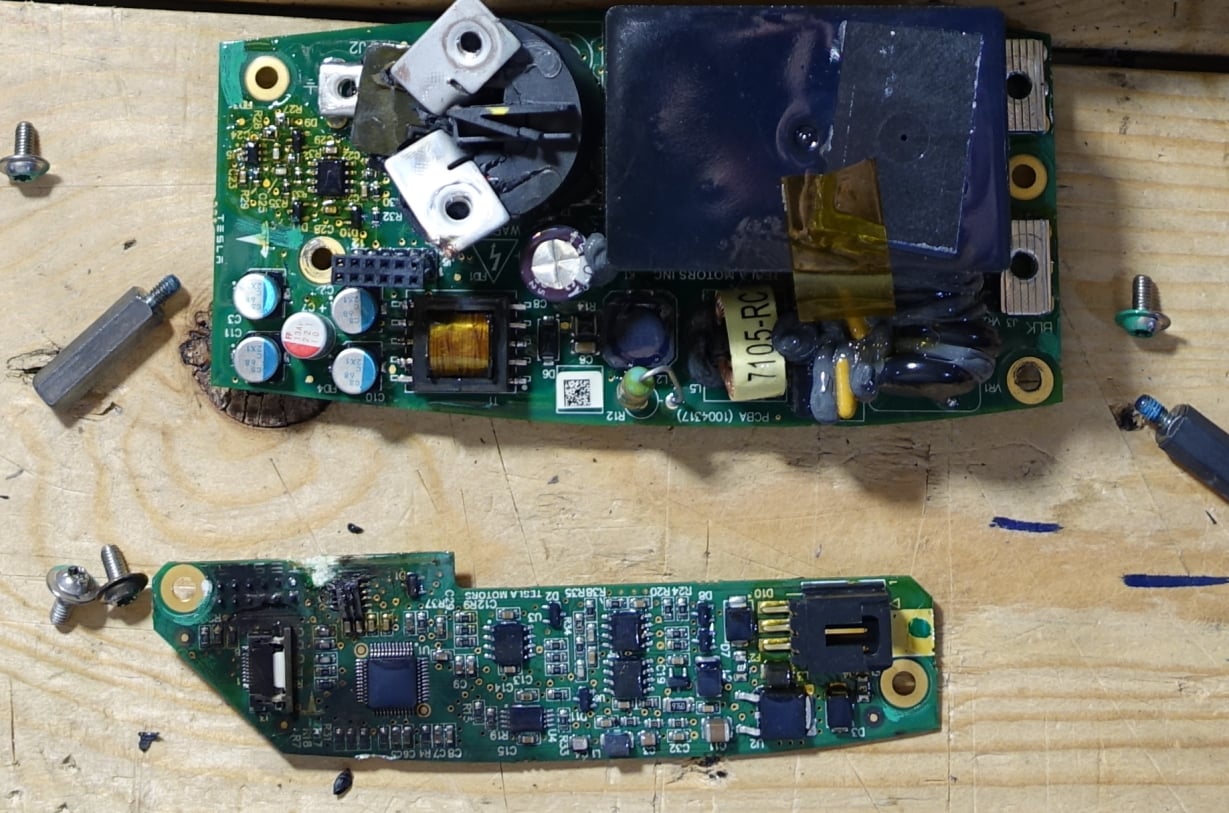

There are 3 circuit boards. The power board, the logic board, and the LED board. The logic board's 3 pin connector has the purple sense pin from the NEMA adaptors at the top, the blue power output to the handle's RF module in the middle, and the purple pilot pin to the handle at the bottom. The latter two of mine were obviously pulled out along with the rest of the cord.

logic board removed:

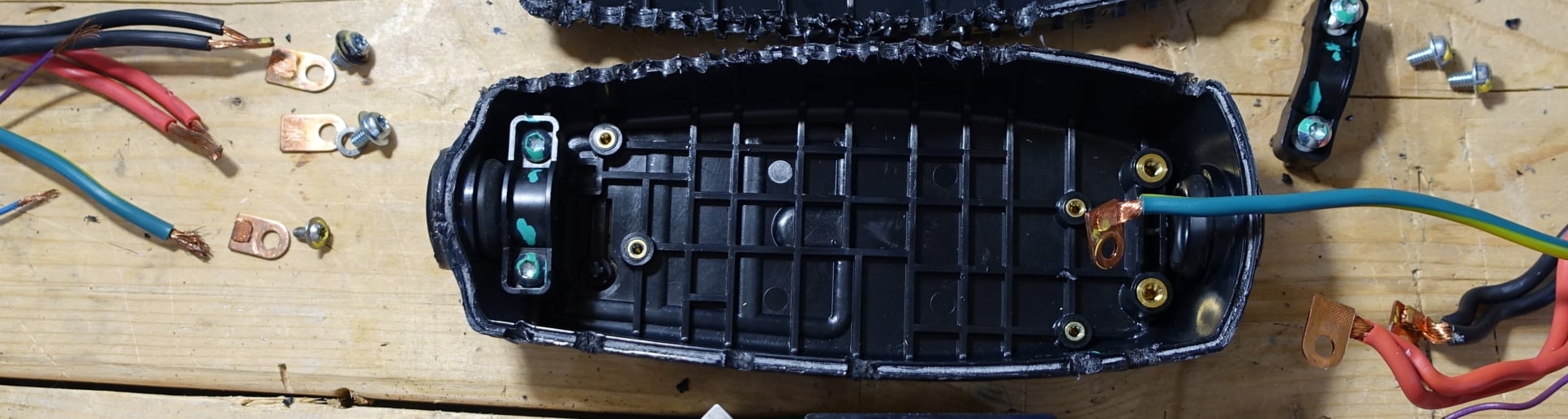

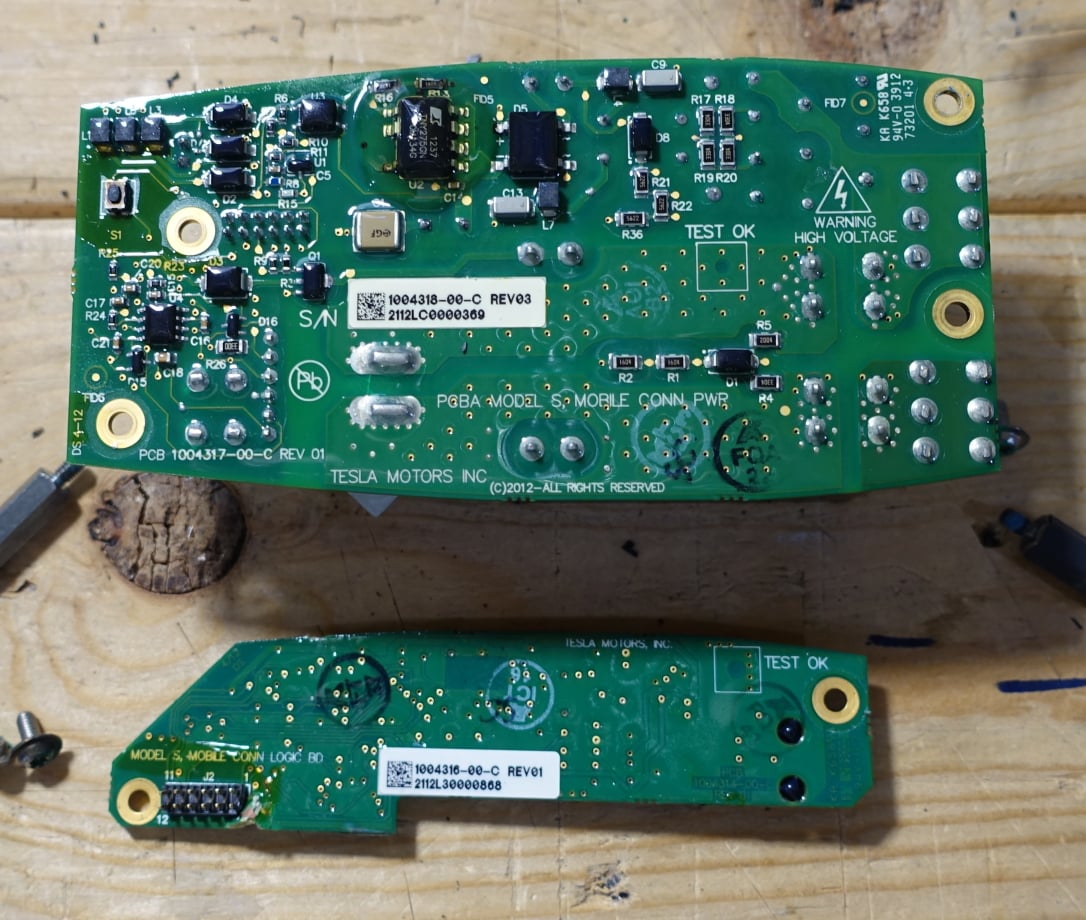

Both boards removed. The AC inputs to the right, relay and GFCI CT at the left. The power and logic boards are interconnected with a 12 pin header. Both boards are covered with a thin layer of clear epoxy.

back:

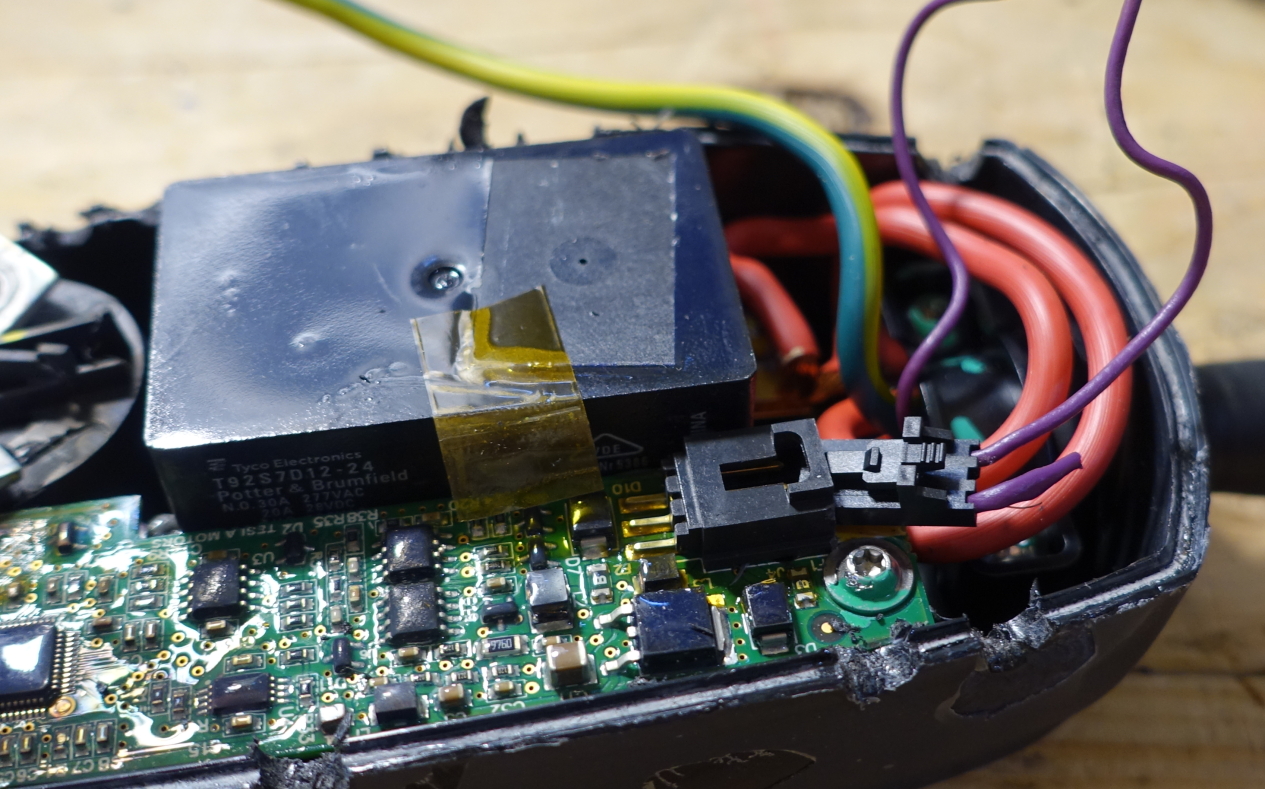

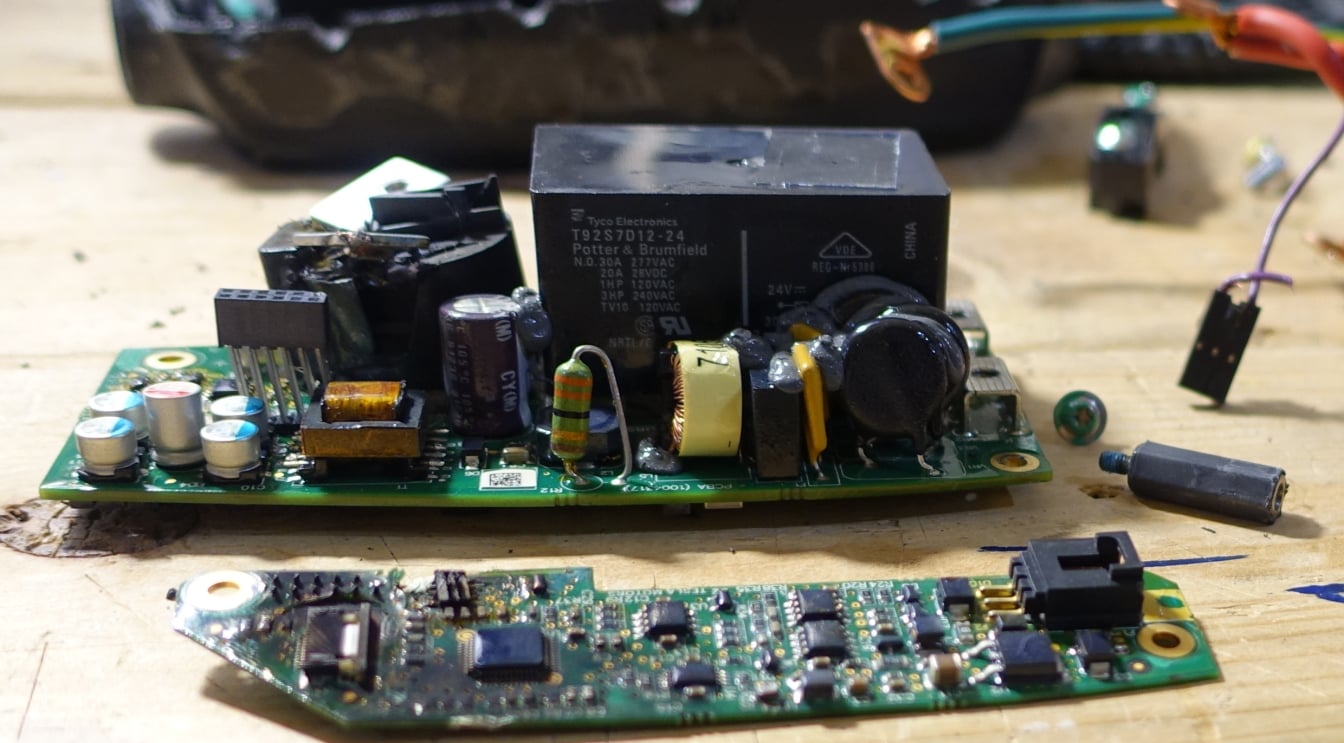

Side, interestingly the AC relay (Tyco T92S7D12-24) is listed for only 30A at 277V. The datasheet however does show this model can be used at 40A at upto 277VAC but only for resistive loads and at a much reduced lifetime (only 6000 cycles).

Left with a useless UMC box, I decided to open it up and take a look around. This particular UMC met its demise by having the cord forcibly pulled out of the UMC box while actively charging.

The metal and rubber outer shell was easy enough to get off, however the assembled plastic box appears to have been surrounded by an injected plastic that sealed the inner box in a cover of melted plastic sealing all the gaps and entombing the inner box.

Suffice it to say, the inner top and bottom parts of the plastic box were welded or glued very well, I had to drill out one entire side and then pry around the rest. Luckily the inside was not injected with plastic like others have found in the handle and other parts.

A quick look reveals that as the cord was pulled out it bent the high voltage output connections driving one of them into the logic board where it intersected a ground plane (among other things). The magic smoke was released in the process. Also note (not shown) that in the process, the plastic around one of the pins inside the box-wall cable to NEMA interconnection melted slightly, undoubitly due to the ground short inside the UMC box.

All of the AC wires (and ground) are crimped onto copper plates before screwing into the power board. Makes a good connection but it was also the point of failure.

There are 3 circuit boards. The power board, the logic board, and the LED board. The logic board's 3 pin connector has the purple sense pin from the NEMA adaptors at the top, the blue power output to the handle's RF module in the middle, and the purple pilot pin to the handle at the bottom. The latter two of mine were obviously pulled out along with the rest of the cord.

logic board removed:

Both boards removed. The AC inputs to the right, relay and GFCI CT at the left. The power and logic boards are interconnected with a 12 pin header. Both boards are covered with a thin layer of clear epoxy.

back:

Side, interestingly the AC relay (Tyco T92S7D12-24) is listed for only 30A at 277V. The datasheet however does show this model can be used at 40A at upto 277VAC but only for resistive loads and at a much reduced lifetime (only 6000 cycles).