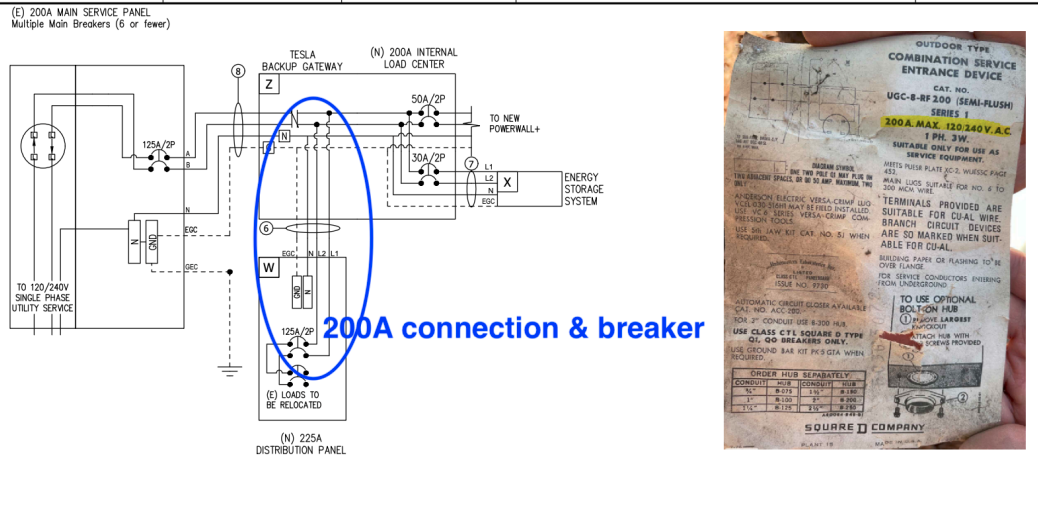

Tesla is installing a 12KW system with 1 PW+ and 1 PW. These are feeding a Gateway 2 via 50A and 30A breakers, along with 125A from my main panel. My main panel is an old Square D 200A panel that supports only 3 circuits, with 1 circuit at a max of 125A. I currently have 3 circuits on my main panel, 100A for my house subpanel, 30A for a pool subpanel, and 25A for an AC. The Gateway 2 will receive 125A from the grid via one circuit from my main panel and all circuits will be relocated to the backup subpanel. Tesla's connection from the Gateway 2 to the backup subpanel is currently wired and backfeed as 125A. I've requested many many times to upsize this to 200A, they have so far refused. One claim is that load calculation shows I only need 124A. I told them really? They know for sure it's 124A and not 126A? How can I get them to upsize it? I'm ready to just buy the wire and 200A breaker myself and have it ready for my install in 2 weeks and give it to the installer. Any ideas why what I'm asking for can't be done. Here is the picture:

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gateway to Backup Subpanel connection

- Thread starter schan1w

- Start date

That wont work, the tesla installer will follow the diagrams and will not install anything thats not on them (including, for example, if you asked for a 14-50 outlet that was not on the drawings).I'm ready to just buy the wire and 200A breaker myself and have it ready for my install in 2 weeks and give it to the installer. Any ideas why what I'm asking for can't be done. Here is the picture:

I cant answer the technical question, but will tell you to not expect to buy parts and hand them to your installer and expect them to do anything at all other than give them back to you and say "sorry we cant do that".

If this is a hot button for you, you will need to get it worked out (and included on any install drawings etc) before installation, including canceling your installation until its worked out to your satisfaction (or you decide to not push it any longer).

miimura

Well-Known Member

The most you can do is bring this to the attention of the city inspector when they sign off your system. If they say it's OK, then there's nothing to worry about. If the inspector says you're right, Tesla has to make good on it at no cost to you.

Also, there's no guarantee what brand or type of new backup loads panel they will install, so there is no way for you to buy the correct 200A breaker in advance anyway. It doesn't have to be the same as your existing combined service panel. For example, my installation has a Square D main service panel and they installed a GE backup loads panel. The breakers are not compatible.

Also, there's no guarantee what brand or type of new backup loads panel they will install, so there is no way for you to buy the correct 200A breaker in advance anyway. It doesn't have to be the same as your existing combined service panel. For example, my installation has a Square D main service panel and they installed a GE backup loads panel. The breakers are not compatible.

The most you can do is bring this to the attention of the city inspector when they sign off your system. If they say it's OK, then there's nothing to worry about. If the inspector says you're right, Tesla has to make good on it at no cost to you.

Also, there's no guarantee what brand or type of new backup loads panel they will install, so there is no way for you to buy the correct 200A breaker in advance anyway. It doesn't have to be the same as your existing combined service panel. For example, my installation has a Square D main service panel and they installed a GE backup loads panel. The breakers are not compatible.

The panel and breakers are all specified in the drawings and plans. Those are submitted with the permit application also. I believe that's a requirement to specify the brand / model of panel and breakers. So I know exactly which panel and breakers they are using as well as wire sizing.

I would heed the advice of @jjrandorin and @miimura. It is great advice.

If you really want that 200A panel, you may need to start over and use a different installer/contractor.

Either way, I would get it resolved before the install.

All the best,

BG

If you really want that 200A panel, you may need to start over and use a different installer/contractor.

Either way, I would get it resolved before the install.

All the best,

BG

wwhitney

Active Member

The OP's request is reasonable for futureproofing but apparently Tesla doesn't care.

The simplest practical thing the OP could do would be to find out the make and model number of the 225A MLO panel shown in the wiring diagram. As long as that is a convertible panel (the main lugs can be swapped for a main breaker), and it's close to the Backup Gateway, it wouldn't be hard to upgrade the feeder and breaker to 200A in the future, if necessary. Even if it's not convertible, it might be possible to backfeed a 4 position 200A branch breaker.

Cheers, Wayne

The simplest practical thing the OP could do would be to find out the make and model number of the 225A MLO panel shown in the wiring diagram. As long as that is a convertible panel (the main lugs can be swapped for a main breaker), and it's close to the Backup Gateway, it wouldn't be hard to upgrade the feeder and breaker to 200A in the future, if necessary. Even if it's not convertible, it might be possible to backfeed a 4 position 200A branch breaker.

Cheers, Wayne

miimura

Well-Known Member

I have a related question about breaker vs. lugs on a subpanel like this.The OP's request is reasonable for futureproofing but apparently Tesla doesn't care.

The simplest practical thing the OP could do would be to find out the make and model number of the 225A MLO panel shown in the wiring diagram. As long as that is a convertible panel (the main lugs can be swapped for a main breaker), and it's close to the Backup Gateway, it wouldn't be hard to upgrade the feeder and breaker to 200A in the future, if necessary. Even if it's not convertible, it might be possible to backfeed a 4 position 200A branch breaker.

Cheers, Wayne

In my original installation in 2018, the installer wasn't going to put any breaker at the input to the Generation Panel. I have a Gateway 1 and one set of Gateway Backup lugs goes to an original subpanel and the other set goes to the Generation Panel. My solar was relocated from the main panel to the Generation Panel and of course, the Powerwalls land in the Generation Panel. I thought it was odd that there were only lugs on the feeder to the Generation Panel and mentioned it to the installer. He responded by disconnecting the feeder from the input lugs and landing it on a newly installed breaker, 100A if memory serves correctly. Without this breaker, there would be no feeder breaker between the Generation Panel and the original subpanel that has most of my household loads. The grid input to the Gateway is fed with the 125A breaker that originally fed the original subpanel.

So, the actual question is - does a Generation panel require a feeder breaker? When off-grid there would no feeder breaker between the subpanel and Generation Panel. There is no actual danger of overload because the Powerwalls will shut down if overloaded more than 2x30A and even adding the solar output, the feeder would not be overloaded. I suppose the only overload situation would be 125A grid + 2x30A PW + 40A solar. However, adding a 100A breaker at the top of the Generation Panel would not actually address that situation.

wwhitney

Active Member

The current path from the grid to the Generation Panel will pass through one or more breakers before the Backup Gateway; call the smallest rating of those breakers X. It will also pass through some feeder conductors going from the Backup Gateway to the Generation Panel, call their ampacity Y. Then if the Generation Panel has busbar rating Z, and all non-grid power sources are in the Generation Panel:

When Z >= X and Y >= X, there's no need for a main breaker in the Generation Panel.

When Z < X, then the Generation Panel needs a main breaker rated not more than Z, to protect its bus from the grid.

When Y < X, then the Generation Panel needs a main breaker rated not more than Y, to comply with the feeder tap rules.

Cheers, Wayne

When Z >= X and Y >= X, there's no need for a main breaker in the Generation Panel.

When Z < X, then the Generation Panel needs a main breaker rated not more than Z, to protect its bus from the grid.

When Y < X, then the Generation Panel needs a main breaker rated not more than Y, to comply with the feeder tap rules.

Cheers, Wayne

godbreath

Member

I'm currently going through a similar situation. My problem though was that they wouldn't send over the designs until the day of the install. It's been two months since the install, calls with multiple advisors (who give an excuse of either you don't need that much load, or the gateway/panel doesn't support higher than 125a). But at least right now I can run on self-consumption mode while they sort it out.

See 'whole home backup' confusion

See 'whole home backup' confusion

The OP's request is reasonable for futureproofing but apparently Tesla doesn't care.

The simplest practical thing the OP could do would be to find out the make and model number of the 225A MLO panel shown in the wiring diagram. As long as that is a convertible panel (the main lugs can be swapped for a main breaker), and it's close to the Backup Gateway, it wouldn't be hard to upgrade the feeder and breaker to 200A in the future, if necessary. Even if it's not convertible, it might be possible to backfeed a 4 position 200A branch breaker.

Cheers, Wayne

I do know the model of everything and am considering upgrading in the future if Tesla doesn't fix it. The 225A backup subpanel is being backfeeed by a 125A breaker from the Gateway 2. It should be backfeed by a 200A breaker. Just the wires and breaker need to be changed. The cost difference is minimal, I don't know why Tesla refuses to make the change. The reasons given are not correct. Basically, they said I don't need it because I'm only getting 125A from the grid and my load calc is 124A.

It shouldn't be hard to do because the Gateway 2 should be installed right next to the 225A backup subpanel. The material cost difference is probably less than $100.

Most 200A branch breakers are 4 positions and are limited in where they can go in the panel. So for a 200A supply, it would typically be more convenient to use a 200A main breaker.

Cheers, Wayne

I agree. I'm not sure why the design uses a backfed breaker instead of a main breaker. The panel does support 200A backfed 4 position breaker. It's a HOM2040L225PRB. The breaker they are using is HOM2125. There is a 200A version that's 4 position backfed. They are using a HOM4RK2HA retaining kit that supports 125A to 200A backfeed.

wwhitney

Active Member

I think a branch breaker plus a holddown kit is noticeably cheaper than a main breaker. Particularly for a 225A frame size in the main breaker vs a normal 125A 2 position branch breaker.I agree. I'm not sure why the design uses a backfed breaker instead of a main breaker.

Cheers, Wayne

Vines

Active Member

There is no technical reason why you cannot have a 200A subfeed from the GW2 to the 225 essential loads subpanel, except they might not be easily available/extra expensive right now. There is a widespread shortage of main breakers right now, so when you can find them they are expensive. Increasing this feed to 200A will give the slight benefit that when you do try to draw more than 125A down the road after your second EV the 3 sources can combine to serve your loads.Tesla is installing a 12KW system with 1 PW+ and 1 PW. These are feeding a Gateway 2 via 50A and 30A breakers, along with 125A from my main panel. My main panel is an old Square D 200A panel that supports only 3 circuits, with 1 circuit at a max of 125A. I currently have 3 circuits on my main panel, 100A for my house subpanel, 30A for a pool subpanel, and 25A for an AC. The Gateway 2 will receive 125A from the grid via one circuit from my main panel and all circuits will be relocated to the backup subpanel. Tesla's connection from the Gateway 2 to the backup subpanel is currently wired and backfeed as 125A. I've requested many many times to upsize this to 200A, they have so far refused. One claim is that load calculation shows I only need 124A. I told them really? They know for sure it's 124A and not 126A? How can I get them to upsize it? I'm ready to just buy the wire and 200A breaker myself and have it ready for my install in 2 weeks and give it to the installer. Any ideas why what I'm asking for can't be done. Here is the picture:

View attachment 729628

If you were to pull 200A through your panel with that 200A feed, then both the Powerwall and Powerwall+ would all work together to serve those loads, especially if Site control was set.

As long as the panel has the main breaker slot, you could change this afterwards if you choose but you won't have the advantage of the Site control to manage that 125A breaker in your main service panel.

From those I have seen, the 200A 4 pole units do not have a hold down, so cannot be backfed.

I have a related question about breaker vs. lugs on a subpanel like this.

In my original installation in 2018, the installer wasn't going to put any breaker at the input to the Generation Panel. I have a Gateway 1 and one set of Gateway Backup lugs goes to an original subpanel and the other set goes to the Generation Panel. My solar was relocated from the main panel to the Generation Panel and of course, the Powerwalls land in the Generation Panel. I thought it was odd that there were only lugs on the feeder to the Generation Panel and mentioned it to the installer. He responded by disconnecting the feeder from the input lugs and landing it on a newly installed breaker, 100A if memory serves correctly. Without this breaker, there would be no feeder breaker between the Generation Panel and the original subpanel that has most of my household loads. The grid input to the Gateway is fed with the 125A breaker that originally fed the original subpanel.

So, the actual question is - does a Generation panel require a feeder breaker? When off-grid there would no feeder breaker between the subpanel and Generation Panel. There is no actual danger of overload because the Powerwalls will shut down if overloaded more than 2x30A and even adding the solar output, the feeder would not be overloaded. I suppose the only overload situation would be 125A grid + 2x30A PW + 40A solar. However, adding a 100A breaker at the top of the Generation Panel would not actually address that situation.

The answer is "it depends" If this panel is exposed to sources that are larger than its wire, and busbar, it does need a main breaker.

Generation panels in general have all the sources inside them, so typically are exposed to power from either the main breaker or from the sources inside them. So if the generation panels subfeed wire, and panel are 125A rated, then it does not need a main breaker as long as the sources within it are less than 125A.

However, if there was a 200A breaker in the main which fed the Gateway then using 125A wire and generation panel would require using a 125A main breaker in the generation panel.

Also if a generation panel has more than 6 sources of power, it needs a main breaker as well for ease of disconnection of power.

Outside of cost savings for Tesla, I think this is another area where the Backup Switch proves to be useful if it can get all the Energy providers on board. Not having to move all loads to a new panel makes it easier to add other loads in the future, but of course you need to make sure you balance it out on your own to make sure your PWs can handle your load.

I think a branch breaker plus a holddown kit is noticeably cheaper than a main breaker. Particularly for a 225A frame size in the main breaker vs a normal 125A 2 position branch breaker.

Cheers, Wayne

Ah, bingo. Cost savings. Thanks for clarifying! Did a little digging, the 200A breaker is $325 and the 125A breaker is $100 on Amazon. I was wrong about the material costs being under $100. The cost difference between 1 and 3/0 wire is about $3 per foot. Maybe 10 feet per wire, or about $120. Total cost difference retail is then about $350. For Tesla, it's probably a lot less. It's quite annoying for a $45K retail project.

SCHNEIDER ELECTRIC 120/240-Volt 125-Amp HOM2125 Miniature Circuit Breaker 120/240V 125A, Black - Thermal Circuit Breakers - Amazon.com

SCHNEIDER ELECTRIC 120/240-Volt 125-Amp HOM2125 Miniature Circuit Breaker 120/240V 125A, Black - Thermal Circuit Breakers - Amazon.com

www.amazon.com

For what it's worth, I offered to pay for the cost difference. Let's see what they say.

Similar threads

- Replies

- 5

- Views

- 582

- Replies

- 9

- Views

- 669

- Replies

- 10

- Views

- 2K