I have two questions for everyone in here who is familiar with connecting the Gen 3 Wall Connector.

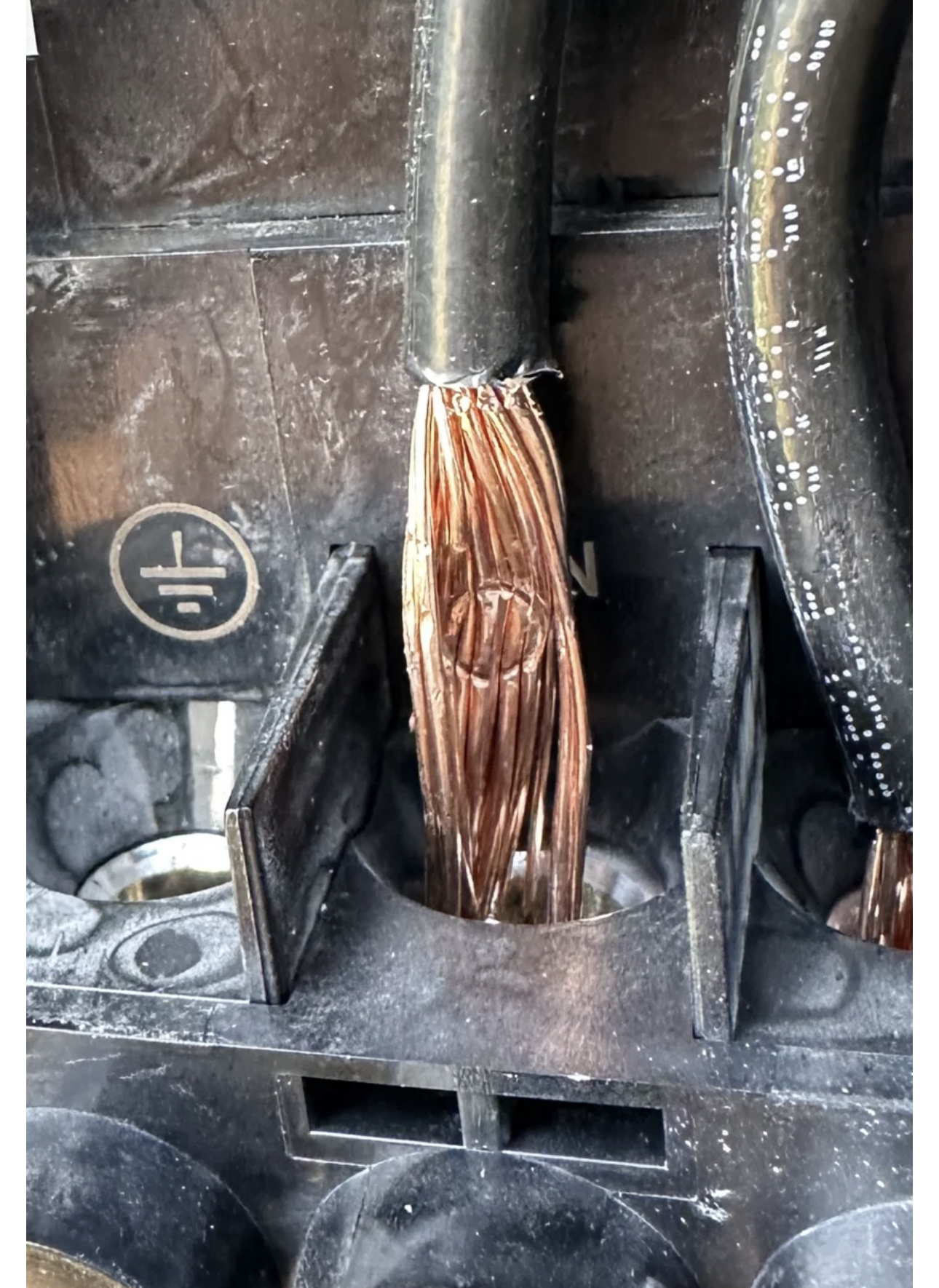

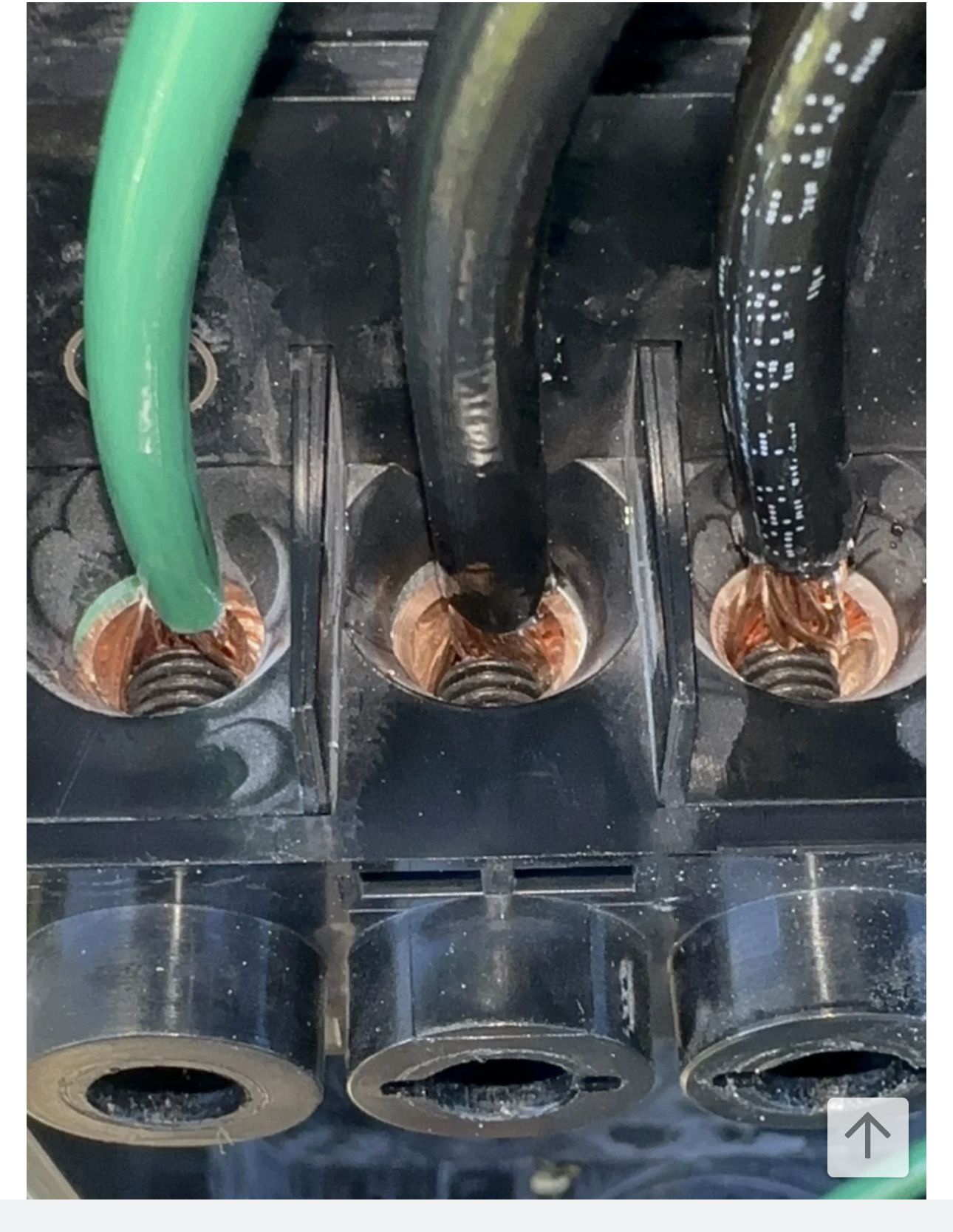

1. I had issues with the way my electrician connected the wires - he didn’t twist them - so all the strands weren’t making good contact. I took them out, re-twisted them and landed them better in the terminal. I didn’t have enough room to shorten wires and re-terminate. As you can see, the wires had impressions/use from backing out and retightening. I landed the terminals on the same spot of the used wire.

Are there any safety risks to doing this? Worried if the wire couldn’t handle the load due to structural integrity issues - what would happen?

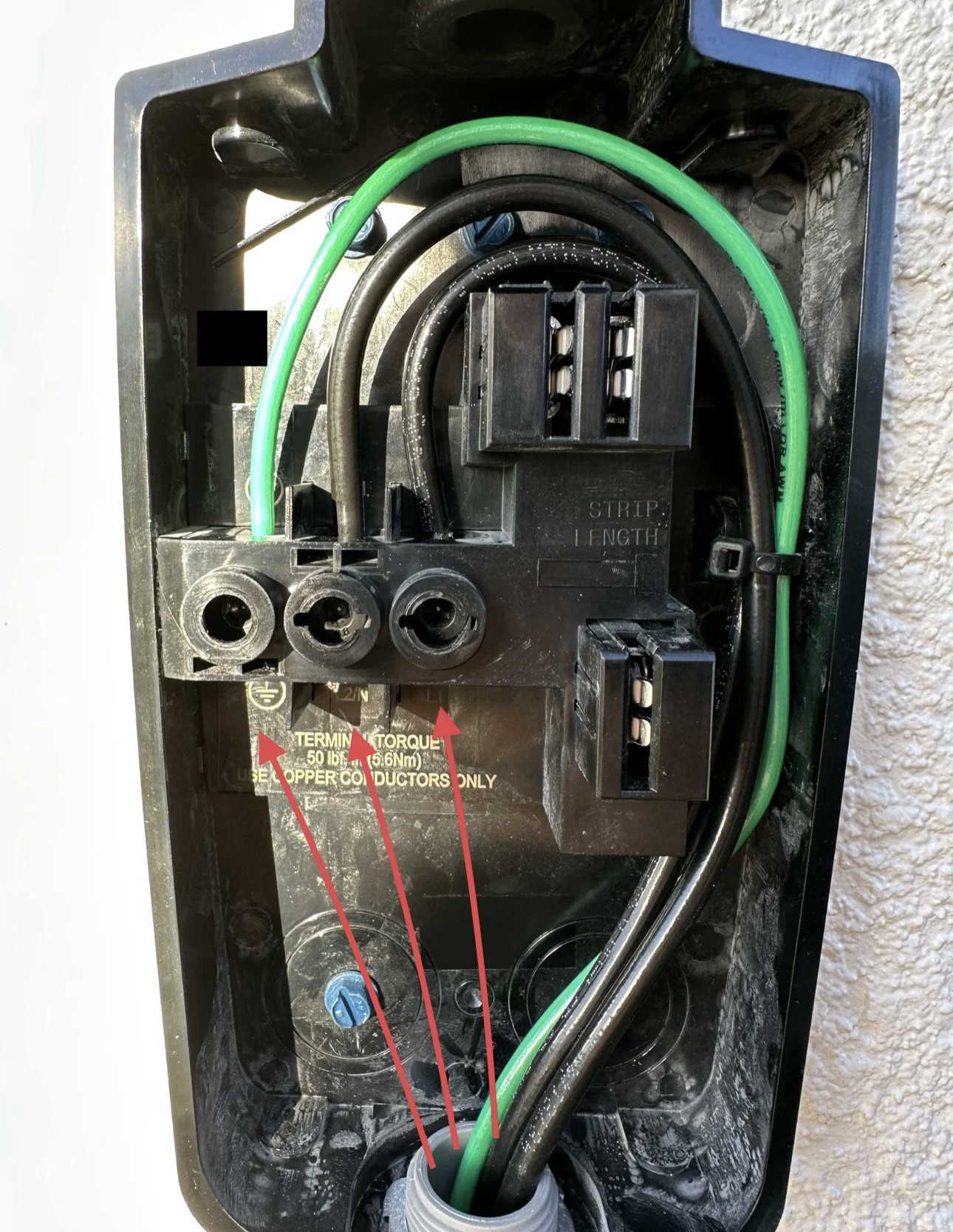

2. If I ever needed to clip the wire and shorten it due to a bad connection, would I have any issues running it this way? As long as there wasn’t excess slack and it went straight to the connectors like this?

1. I had issues with the way my electrician connected the wires - he didn’t twist them - so all the strands weren’t making good contact. I took them out, re-twisted them and landed them better in the terminal. I didn’t have enough room to shorten wires and re-terminate. As you can see, the wires had impressions/use from backing out and retightening. I landed the terminals on the same spot of the used wire.

Are there any safety risks to doing this? Worried if the wire couldn’t handle the load due to structural integrity issues - what would happen?

2. If I ever needed to clip the wire and shorten it due to a bad connection, would I have any issues running it this way? As long as there wasn’t excess slack and it went straight to the connectors like this?