After failing to find a proper jack pad for my Model S, I decided to make one myself out of the wood. I wanted something that would use entire jacking surface and would not slip. I also wanted something that would self-center to use this entire jacking surface.

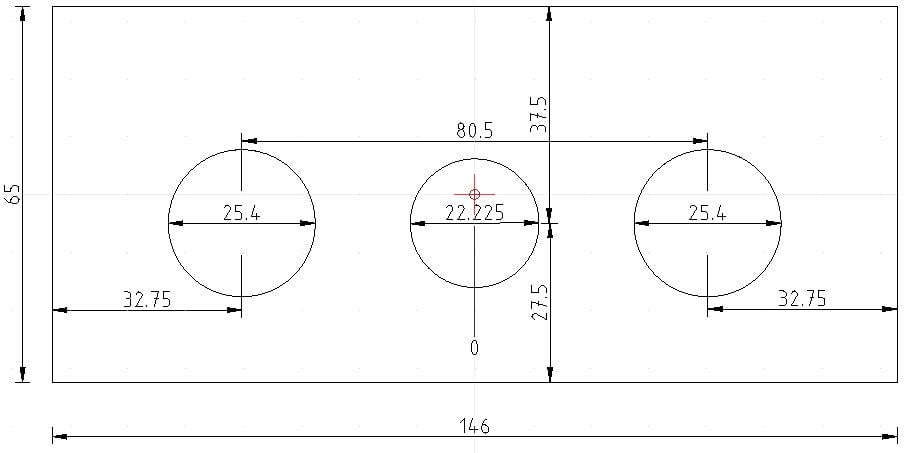

It took me quite a few hours to get it right, so I am sharing my final dimensions with the community (all dimensions are im mm).

Here is what I needed to get from the local home improvement store:

A piece of 2x3 stud (cut to 146mm in length)

1 inch poplar dowel (cut to 30mm, used 2 pieces)

7/8 inch poplar dowel (cut to 30mm, used 1 piece)

I drilled 10mm deep holes for the dowels to embedded them and glued them in place. So these pings are sticking-out by 20mm. This way they my pins are serving as a guides only and not pushing on anything underneath the jacking surface.

The most expensive part was buying the forstner drill bits for these 1" and 7/8" holes (didn't have them at home). The rest of the materials were less then $15.

You can see the pictures of my rig below.

It took me quite a few hours to get it right, so I am sharing my final dimensions with the community (all dimensions are im mm).

Here is what I needed to get from the local home improvement store:

A piece of 2x3 stud (cut to 146mm in length)

1 inch poplar dowel (cut to 30mm, used 2 pieces)

7/8 inch poplar dowel (cut to 30mm, used 1 piece)

I drilled 10mm deep holes for the dowels to embedded them and glued them in place. So these pings are sticking-out by 20mm. This way they my pins are serving as a guides only and not pushing on anything underneath the jacking surface.

The most expensive part was buying the forstner drill bits for these 1" and 7/8" holes (didn't have them at home). The rest of the materials were less then $15.

You can see the pictures of my rig below.