The Blue Owl

Endangerous Herbivore

OK, thanks for bringing up the Regera, because this actually makes things interesting.

So the Regera's powertrain looks like this:

(Source: Engineering Explained: How The Koenigsegg Regera Hypercar Drives Without A Gearbox)

Those two electric motors actually are direct drive, albeit through CV axles. They're YASA 750s, the current version of which is the YASA 750 R.

Here's the YASA 750 R datasheet: https://www.yasa.com/wp-content/uploads/2018/01/YASA-750-Product-Sheet.pdf

It weighs 37 kg, produces 200 kW peak power at 700 V or 100 kW at 350 V, is rated for 70 kW continuous, and is designed to run from 0 to 3250 RPM. (I'd also like to note that 3250 RPM on a Model S Performance rear tire is 412 km/h.) So, weight isn't actually as bad as I was thinking.

Here's the problem, though.

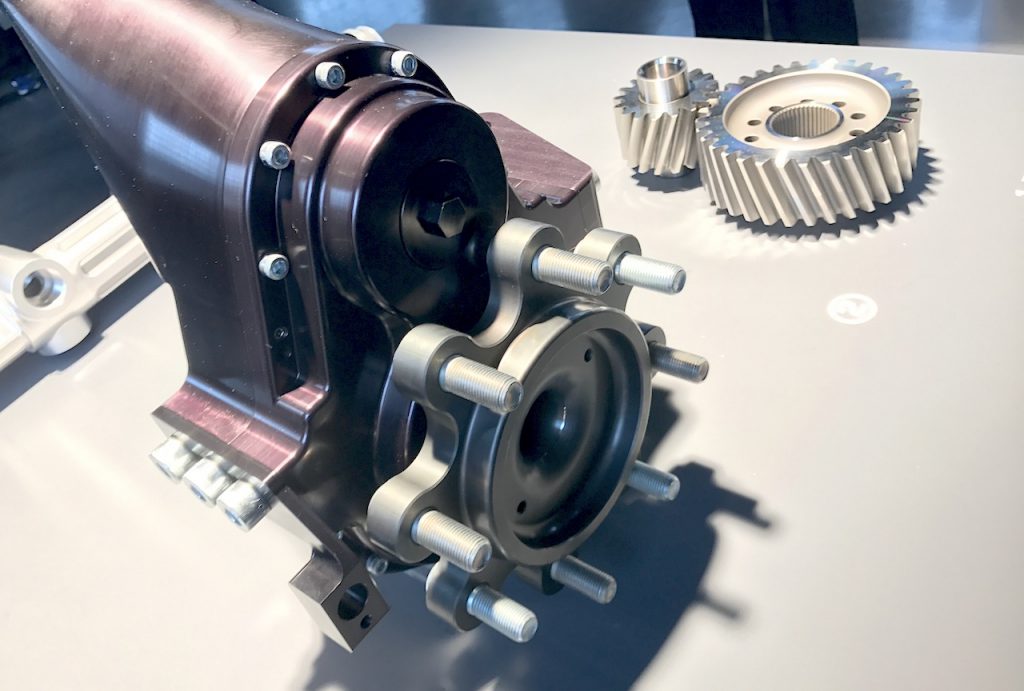

View attachment 473378

(Annoyingly, Adobe Reader gave me a black background on that copy, so the text on the outside isn't very readable.)

The motor's about as efficient - 93%+ - as Tesla's PMSRM motors at like 2400 RPM and above. Problem is, 2400 RPM is 304 km/h.

At a more reasonable 130 km/h, you're just about touching 86% efficiency. At city speeds, you're under 80% efficiency. That's just garbage efficiency.

...and those are best case numbers at fairly low torques.

You can quite clearly see where reduction gearing would help this motor out, as the meat of the efficiency band is way up in the RPMs that it simply can't achieve.

The rest of the Regera's powertrain is irrelevant for a Tesla, and the "direct drive" when referred to from the engine's perspective is going through both a reduction gear (as Tesla's existing powertrains do) and a torque converter (which, uh, that basically makes it a really inefficient form of CVT, I can't call that direct drive!)

Oh, and Tesla's claiming the Roadster will have 10,000 Nm at the wheels. On three of these motors that would require about 4.22:1 reduction gearing to achieve.

Edit: Also, note that the thing is current-limited up to like 2500 RPM. That means that you don't get full power until then, and that means that you don't get full power until 317 km/h. I highly doubt that Tesla's ditching the reduction gearing.

I am not a mechanical engineer, but I am an engineer, and reading the explanations from contributors like yourself, @KarenRei, @Fact Checking, @Krugerrand, @JRP3, @mongo, or the faithful departed @neroden, and many others (apologies for not mentioning everybody) feels to me like connecting to the whole Internet via Neuralink. Just wanted to say thanks for helping me understand better.

(*walking away slowly*).

Last edited: