Like many others, my inner tail lights on the hatch were both leaking. They would both fill with water during a heavy rain and more recently, they would leak though the hatch itself and get the trunk carpet wet. I had already ordered new gaskets for the tail lights but they both had residue inside the housing from water leaking in them so many times. The last straw was from a recent rain storm that had also managed to dump a massive amount of pollen inside one of the housings and there was no real way to flush it out without taking everything apart. I'm not going to go into the details of how to remove and install the light housings, there are plenty of guides and videos on that. This will just be on taking the actual housings apart for cleaning and repair.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Inner tail light leak repair, housing disassembly, and cleaning.

- Thread starter jelloslug

- Start date

First off is to remove the old gasket. You can see where the old gasket drooped and allowed water and debris in.

Here is the residue inside the lens that had built up over time.

The other side was similar:

Here is the residue inside the lens that had built up over time.

The other side was similar:

Next is to remove the clear lens. The lens seems to be most likely glued on with a cyanoacrylate (super glue) and because of that, the joint will be brittle. A light tap on the black housing will crack the joint. You will be able to see where the joint has broken free by a change in color at the joint from a solid black to a clearish white.

After carefully tapping around the edges of the black housing, the lens should pop off. If you have a stubborn area, CAREFULY pry close to the stuck area to pop it free. The Lexan lens is brittle and can crack if you pry too hard on it.

After the lens is off, you can remove the wiring harnesses. I suggest that you also remove the label stickers off the harness after you remove them from the lens assembly. The coating on the sticker does not age will and flakes off into a fine white powder that will end up inside you freshly cleaned lens.

Next, remove the four black screws and remove the main inner lens assembly from the housing.

You can then access the three small torx screws from the inside that hold the remaining circuit board in.

With that board out of the way, you then have access to completely clean the black housing.

After carefully tapping around the edges of the black housing, the lens should pop off. If you have a stubborn area, CAREFULY pry close to the stuck area to pop it free. The Lexan lens is brittle and can crack if you pry too hard on it.

After the lens is off, you can remove the wiring harnesses. I suggest that you also remove the label stickers off the harness after you remove them from the lens assembly. The coating on the sticker does not age will and flakes off into a fine white powder that will end up inside you freshly cleaned lens.

Next, remove the four black screws and remove the main inner lens assembly from the housing.

You can then access the three small torx screws from the inside that hold the remaining circuit board in.

With that board out of the way, you then have access to completely clean the black housing.

Last edited:

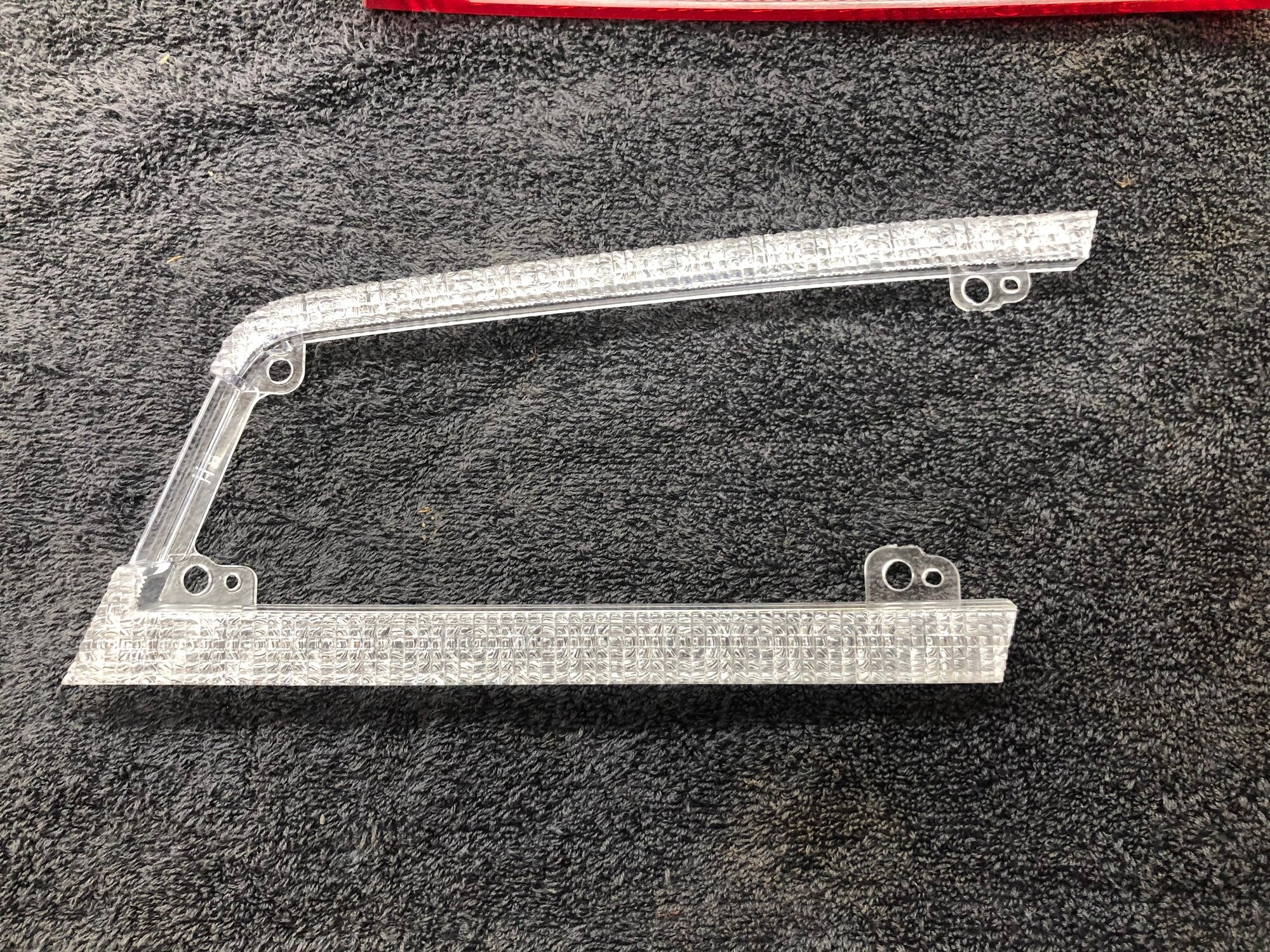

With the inner lens assembly out of the housing, you can then take it all apart to clean each piece separately. First is to remove the four torx screws that hold the main board in.

Next is to remove the two torx screws that hold in the back up led board.

Now you can take out the three torx screws that hold in the backup lens.

With the back up lens assembly out, you can then remove the brake light led diffuser.

It is possible to remove the red parts of the lens assembly but you have to break welded lugs off so unless you cannot get it clean otherwise, I don't suggest that you take the inner lens assembly apart any further.

Next is to remove the two torx screws that hold in the back up led board.

Now you can take out the three torx screws that hold in the backup lens.

With the back up lens assembly out, you can then remove the brake light led diffuser.

It is possible to remove the red parts of the lens assembly but you have to break welded lugs off so unless you cannot get it clean otherwise, I don't suggest that you take the inner lens assembly apart any further.

Next is to reattach the clear lens to the black plastic housing. You can use a superglue with an activator but you have to be very precise in the application and there is no room for error when you put the two halves together. On top of that, superglue can attack the material of the inner lens if you apply too much of it. I opted for a clear two part epoxy from JB Weld. You want the one that sold in dispenser bottles rather than the big syringe. The kit is about $10 at Lowes. The first thing to do is to mask off the red portions of the lens assembly. This is important as the epoxy is stringy and apparently the red parts of the lens have a static charge that will attract the tiny strands of epoxy when you are applying it.

Now mix up enough epoxy for the perimeter of the housing. I used two three inch long stripes of the A and B portions and then mixed it for at least 1 minute. You then have about five minutes of working time to apply the epoxy. I used the cut off end of a Q-tip to apply the epoxy to the rough groove surface of the housing making sure to leave no gaps.

Don't forget to remove you masking tape and then carefully place your lens on the black housing. You will want to have to strips of making tape ready to go when you put the lens on the housing. Use the tape to apply pressure to the lens to make a tight seal. A solid black strip where the epoxy is at on the lens indicates a tight seal. If you cannot get a solid seal on the first attempt, you can apply more epoxy to the outside of the seam once the first epoxy has firmed up for at least an hour.

Finally, once the epoxy has cured to the point that it is not tacky anymore, you can put the new gaskets on.

Now you can put everything back together on the car and hopefully you have stopped all the leaks. The gaskets were about $12 each and the epoxy was about $10. You will also need some 3M emblem and trim tape to put the chrome TESLA trim back on. The entire repair come in at under $50 and an afternoon of your time.

Now mix up enough epoxy for the perimeter of the housing. I used two three inch long stripes of the A and B portions and then mixed it for at least 1 minute. You then have about five minutes of working time to apply the epoxy. I used the cut off end of a Q-tip to apply the epoxy to the rough groove surface of the housing making sure to leave no gaps.

Don't forget to remove you masking tape and then carefully place your lens on the black housing. You will want to have to strips of making tape ready to go when you put the lens on the housing. Use the tape to apply pressure to the lens to make a tight seal. A solid black strip where the epoxy is at on the lens indicates a tight seal. If you cannot get a solid seal on the first attempt, you can apply more epoxy to the outside of the seam once the first epoxy has firmed up for at least an hour.

Finally, once the epoxy has cured to the point that it is not tacky anymore, you can put the new gaskets on.

Now you can put everything back together on the car and hopefully you have stopped all the leaks. The gaskets were about $12 each and the epoxy was about $10. You will also need some 3M emblem and trim tape to put the chrome TESLA trim back on. The entire repair come in at under $50 and an afternoon of your time.

Next is to reattach the clear lens to the black plastic housing. You can use a superglue with an activator but you have to be very precise in the application and there is no room for error when you put the two halves together. On top of that, superglue can attack the material of the inner lens if you apply too much of it. I opted for a clear two part epoxy from JB Weld. You want the one that sold in dispenser bottles rather than the big syringe. The kit is about $10 at Lowes. The first thing to do is to mask off the red portions of the lens assembly. This is important as the epoxy is stringy and apparently the red parts of the lens have a static charge that will attract the tiny strands of epoxy when you are applying it.

View attachment 649597

Now mix up enough epoxy for the perimeter of the housing. I used two three inch long stripes of the A and B portions and then mixed it for at least 1 minute. You then have about five minutes of working time to apply the epoxy. I used the cut off end of a Q-tip to apply the epoxy to the rough groove surface of the housing making sure to leave no gaps.

View attachment 649598

View attachment 649599

Don't forget to remove you masking tape and then carefully place your lens on the black housing. You will want to have to strips of making tape ready to go when you put the lens on the housing. Use the tape to apply pressure to the lens to make a tight seal. A solid black strip where the epoxy is at on the lens indicates a tight seal. If you cannot get a solid seal on the first attempt, you can apply more epoxy to the outside of the seam once the first epoxy has firmed up for at least an hour.

View attachment 649600

Finally, once the epoxy has cured to the point that it is not tacky anymore, you can put the new gaskets on.

View attachment 649601

Now you can put everything back together on the car and hopefully you have stopped all the leaks. The gaskets were about $12 each and the epoxy was about $10. You will also need some 3M emblem and trim tape to put the chrome TESLA trim back on. The entire repair come in at under $50 and an afternoon of your time.

Not the original poster but I picked mine up last fall from the service center.Can you please let us know where you found the foam gaskets...I can't seem to locate any...

I used the parts catalog to get the exact number I needed:

Skotty

2014 S P85 | 2023 F-150L

I've got this problem. I'm going to replace the gaskets on both sides soon. I was able to place an order for the parts at the Tesla service center. Not sure if I could have done it via the app; I just went there in person figuring that was the most reliable way to get them to place an order for me.

The part numbers for the lift gate tail lamp gaskets from the Model S 2012-2016 parts catalog (from section 17-Electrical 1740 Exterior Lights, catalog as of 2022-06-06):

1029069-00-B (Left Hand)

1029070-00-B (Right Hand)

I might post some details on trim removal since this thread doesn't have that currently. I know some people reach up through the little hole after removing a small plastic piece, though I might fully remove the interior trim, as I hate working through tiny little spaces if I don't have to. Specifically, my model is a mid-2014 Model S, pre-autopilot, P85 model. Parts are currently on order. It will probably be a couple of weeks before I get the parts and do the service, but I'll post a follow up in this thread when I can.

The part numbers for the lift gate tail lamp gaskets from the Model S 2012-2016 parts catalog (from section 17-Electrical 1740 Exterior Lights, catalog as of 2022-06-06):

1029069-00-B (Left Hand)

1029070-00-B (Right Hand)

I might post some details on trim removal since this thread doesn't have that currently. I know some people reach up through the little hole after removing a small plastic piece, though I might fully remove the interior trim, as I hate working through tiny little spaces if I don't have to. Specifically, my model is a mid-2014 Model S, pre-autopilot, P85 model. Parts are currently on order. It will probably be a couple of weeks before I get the parts and do the service, but I'll post a follow up in this thread when I can.

Skotty

2014 S P85 | 2023 F-150L

UPDATE: I'm replacing the seals today. Unlike others, I loathe the idea of trying to stick my big hands up in those tiny holes, so I fully removed the interior trunk lid trim. It's mostly poppets, BUT there are 2 star head screws near the middle holding the big bottom trim piece on. To get to them, you have to remove the other trim pieces first. I recommend taking off the top piece, then the side pieces, then you can reach the two screws for the big bottom piece.

The plugs for electronics are mostly easy to remove, with the exception of one I had a ton of trouble with. I suppose I should post some pictures for those; I'll consider doing that soon.

The plugs for electronics are mostly easy to remove, with the exception of one I had a ton of trouble with. I suppose I should post some pictures for those; I'll consider doing that soon.

Skotty

2014 S P85 | 2023 F-150L

MINOR UPDATE: On my left tail light, the white wiring you can see in the other pictures actually went under and outside of the old seal (assembly error), and that exacerbated the problem on mine.

Todd Bostic

Member

Wanted to bump this thread. How did the original fix go? I'm tired of buying new inner taillights! TIA for your responses.

Dannietjoh

Member

I too had water ingress after rain or a car wash, it would exit on the right side trough the handle with the close button. After a wash when water was dripping again I popped the handle out and could see little drops of water hanging from the little white wires so I ordered the gasket (both sides). After removal of the units here is what the leaking side looks like:

Seems like a little trend is going on here.

Upon further inspection it seems like the gaskets double sided tape does not properly stick to the unit because there is an edge sticking out all around the opening not giving a flat surface to adhere to.

Since I ordered both sides and got both units out I decided to put them on in reverse, so the double sided tape against the gate, giving it a flat surface (so left side gasket on the right side and right side gasket on the left side obviously). I did this by placing the gasket on the unit and keeping it in place by putting a little piece of tape on both longer edges of the gasket, then push the unit in so that the gasket sticks to the gate. Next I pulled the unit out to verify the gasket was seated correctly and remove the little pieces of tape and then mount the units one final time.

Seems like a little trend is going on here.

Upon further inspection it seems like the gaskets double sided tape does not properly stick to the unit because there is an edge sticking out all around the opening not giving a flat surface to adhere to.

Since I ordered both sides and got both units out I decided to put them on in reverse, so the double sided tape against the gate, giving it a flat surface (so left side gasket on the right side and right side gasket on the left side obviously). I did this by placing the gasket on the unit and keeping it in place by putting a little piece of tape on both longer edges of the gasket, then push the unit in so that the gasket sticks to the gate. Next I pulled the unit out to verify the gasket was seated correctly and remove the little pieces of tape and then mount the units one final time.

Similar threads

- Replies

- 5

- Views

- 520

- Replies

- 21

- Views

- 4K

- Replies

- 5

- Views

- 3K

- Replies

- 16

- Views

- 3K