I have a couple of energy monitors and their CTs in my breaker box, and I was looking at them this weekend because I couldn't remember exactly where I'd placed them. While I was in there I noticed my utility feed connection is looking rather bad - I think it would have ended in a fire had I not noticed it. The electrician is coming to fix it today.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just a reminder to everyone: check your breaker panel occasionally. Mine looks bad!

- Thread starter Electricfan

- Start date

-

- Tags

- Off Topic

fwgmills

Member

This happened to me at my old house. Foundation shifting pulled one of the mains loose in the meter box. I woke up and half the house didn't work. I was *really* lucky it didn't start a fire. The utility company came out and extended all three wires (although he kinda didn't want to) so it wouldn't happen again. The house also had a Zinsco panel so I'm pretty glad we don't live there anymore.

Update: new breaker installed. Electrician says the wire was loose. Pulled it out and cut off the inch or so at the end and re-terminated in new breaker. I have a reminder set monthly to re-check it. Will re-post if it turns brown again.

Update: new breaker installed. Electrician says the wire was loose. Pulled it out and cut off the inch or so at the end and re-terminated in new breaker. I have a reminder set monthly to re-check it. Will re-post if it turns brown again.

Monthly is a bit overzealous - but I do recommend looking over your panels once a year or so to ensure nothing looks like it's overheating.

Monthly is a bit overzealous - but I do recommend looking over your panels once a year or so to ensure nothing looks like it's overheating.

From the picture did it look like it was going bad to you? I'm not an electrician, so I'm hoping I didn't just spend a lot of money for normal wear. The breaker shown in the picture was installed in a completely brand new circuit breaker panel with all new breakers in 2011 when I got my Volt.

Great Dane

Member

Two Things I see in that picture

magnetic pickup coils to measure current

( nothing to do with overheating)

Is that aluminum wire ?

magnetic pickup coils to measure current

( nothing to do with overheating)

Is that aluminum wire ?

aesculus

Still Trying to Figure This All Out

A bit off topic but who's loop inductors are you using? I have a TED 5000 but it's kind of flaky.

DaveWaterloo

Member

I have both TED (The Energy Detective) and an Eyedro for electrical monitoring of whole house and for the HPWC circuit. I much prefer Eyedro (bought on Amazon)...better weekly reports and live dashboard (cloud based software).

From the picture did it look like it was going bad to you? I'm not an electrician, so I'm hoping I didn't just spend a lot of money for normal wear. The breaker shown in the picture was installed in a completely brand new circuit breaker panel with all new breakers in 2011 when I got my Volt.

There was definitely some heating taking place and my guess is that those connections needed to be re-torqued. I was merely suggesting that making it a monthly practice was a bit overkill - I do look at my panels at least once a year to make sure all is well.

Note that if that is your main panel, those top connections are always live unless the meter is pulled, so don't go grabbing a wrench to crank them down unless you know how to deal with them properly and with proper protective equipment. The remainder of connections on breakers can be worked as long as the breaker is off.

Last edited:

Is that aluminum wire ?

Aluminum wire is typically used in the mains drop.

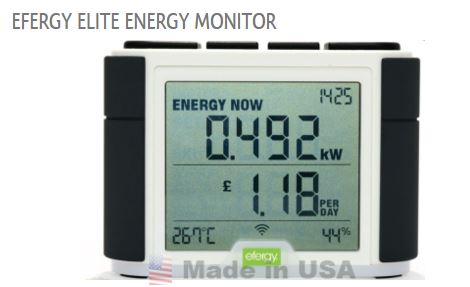

The CTs in the picture go with this monitor:

But I also had a TED energy detective in there. I say "had" because it was doing something weird, so I took it out. One of the CTs for the TED was making a loud buzzing sound. I would never have suspected a magnet could do that. But it sure did. I was worried the vibration might have contributed to loosening the wire so I took it out. The black ones in the picture weren't making any noise, so I left them there.

But I also had a TED energy detective in there. I say "had" because it was doing something weird, so I took it out. One of the CTs for the TED was making a loud buzzing sound. I would never have suspected a magnet could do that. But it sure did. I was worried the vibration might have contributed to loosening the wire so I took it out. The black ones in the picture weren't making any noise, so I left them there.

Aluminum wire is typically used in the mains drop.

Yup. There's nothing wrong with AL wire, especially the alloys in use today. AL wire got a really bad name in the mid-1960's when existing long-haul transmission cable alloys were used to produce home wiring. What hadn't been considered was the effect of how connections were made. The aluminum alloys had different mechanical characteristics (such as expansion/contraction rates under heat), and tended to work their way loose over time. In addition, when two dissimilar metals are in contact with each other, the possibility of galvanic corrosion exists. Both of these created bad connections and in some cases fires.

Today's alloys are very similar mechanically to copper and are designed to reduce/prevent the occurrence of corrosion. For small circuits, copper is still used for a number of reasons - partly because AL got such a bad name in the '60s and '70s, partly because for the metal needed, the cost savings just isn't there. But for large circuits and feeders - like service drops, it can save a pretty significant amount of money.

Note that if that is your main panel, those top connections are always live unless the meter is pulled, so don't go grabbing a wrench to crank them down unless you know how to deal with them properly and with proper protective equipment. The remainder of connections on breakers can be worked as long as the breaker is off.

I was too scared to go near them and called an electrician. He wore thick rubber gloves and taped the ends of the cables while he was installing the new breaker. We didn't pull the meter, which you really SHOULD do. But to pull it you have to call the utility and wait a month for them to come out and remove the tag, then call them back and get them to come back. Huge PIA.

I will check monthly just because I'm super curious if they new connection is going to hold up. But after a while I'm sure I'll check them less frequently. It was pure luck I found the problem. I wonder how many people don't know to check their utility connection and are having electrical problems in their home and don't know the cause.

I was too scared to go near them and called an electrician. He wore thick rubber gloves and taped the ends of the cables while he was installing the new breaker. We didn't pull the meter, which you really SHOULD do. But to pull it you have to call the utility and wait a month for them to come out and remove the tag, then call them back and get them to come back. Huge PIA..

Yes indeed. Thick rubber gloves, thick rubber boots, insulated tools, and safety glasses are all part of a good PPE kit.

My PoCo is easy to work with, they don't mind if someone experienced cuts the seal, does the work, and then calls them to inspect and re-seal. They are concerned about one thing, and that's how the meter is re-installed. If you don't know how to install a meter properly, and there isn't a bypass lever, you can spread the meter contacts and create a bad connection if you're not careful or you try to do it under a load.

Most PoCo's, though, are very strict about their meter installs - so call them first.

Hey, stupid question time: Is it cool to install a disconnect between the meter and your main circuit breaker panel? If I had one I could disconnect power to my panel without having to call the utility! Or is that illegal for some reason?

Panoz

Member

Hmmm. I'm just a very little bit skeptical, E'fan and Flasher. Looking closely at the provided photo, it seems that what is showing is a discolored anti-oxidant...except that looking at the base of the opposite lug, the anti-ox seems to be the same color. Now, if that's so it certainly could be that heat is what caused the discoloration - and the mild amount of 'grease-spreading' that also shows. But mightn't it more innocently simply be aging of the anti-ox?

I wish you could have been there to see what kind of loosening really had been present. Do you know if you're consistently drawing close to the rated ampacity?

As I said, just a little skeptical. It certainly could have been a loosened lug.

Peripherally, a number of the lug sites I inherited (Alaska) have been affixed with what looks like silicone caulk; very obviously to maintain torque. I've not seen that in more...ummm...civilized locations. Would that be silicone and is it NEC-kosher?

I wish you could have been there to see what kind of loosening really had been present. Do you know if you're consistently drawing close to the rated ampacity?

As I said, just a little skeptical. It certainly could have been a loosened lug.

Peripherally, a number of the lug sites I inherited (Alaska) have been affixed with what looks like silicone caulk; very obviously to maintain torque. I've not seen that in more...ummm...civilized locations. Would that be silicone and is it NEC-kosher?

Hey, stupid question time: Is it cool to install a disconnect between the meter and your main circuit breaker panel? If I had one I could disconnect power to my panel without having to call the utility! Or is that illegal for some reason?

Sure - this is done in many cases (I've seen it a lot in California where outdoor disconnects are preferred/required and the larger panel is indoors). In this case, that disconnect becomes your "service equipment" and the main panel becomes a subpanel of that service equipment, requiring a four-wire feed and grounds/neutrals be separated.

- - - Updated - - -

Hmmm. I'm just a very little bit skeptical, E'fan and Flasher. Looking closely at the provided photo, it seems that what is showing is a discolored anti-oxidant...except that looking at the base of the opposite lug, the anti-ox seems to be the same color. Now, if that's so it certainly could be that heat is what caused the discoloration - and the mild amount of 'grease-spreading' that also shows. But mightn't it more innocently simply be aging of the anti-ox?

You can definitely see the anti-ox discolored. I don't think it's just aging, unless the anti-ox wasn't applied to the other conductor, was applied at a different time, or was applied very, very poorly - you would see the same aging appear on the other lug and conductor. Further up the conductor you can see where two very small spots of anti-ox have discolored, and you can see signs of heat making the grease spread more than the other conductor. I can say with almost assured certainty that there was a heating issue there (and for what it's worth, the installer nicked the metal conductors more than I would like - you can see the nicks where the anti-ox is discolored).

Was it minutes from a fire? Probably not. I don't see insulation compromised or any plastic melting. But I believe those are signs of heat and it sounds like the electrician was concerned enough to re-terminate it and replace the breaker.

Peripherally, a number of the lug sites I inherited (Alaska) have been affixed with what looks like silicone caulk; very obviously to maintain torque. I've not seen that in more...ummm...civilized locations. Would that be silicone and is it NEC-kosher?

If it's listed for the purpose, then it's NEC-kosher. The NEC doesn't require nor disallow materials as long as they're listed for the purpose. Contrary to what a lot of electricians believe, anti-ox isn't even required unless installation instructions demand it (NEC 110.3). Most new CO-AL rated terminations work fine without it, but a lot of electricians treat it anyway (belt and suspenders and all).

That said, at the torques required here, I'm not sure the equivalent of Loctite will do much to keep the torque.

green1

Active Member

You can do it, but keep in mind that it just adds another pair of connections which can go bad. So in a case like this you can work on your meter, but there's nothing to say that the same problem wouldn't happen in that disconnect box. You already have a disconnect at the entrance to the panel (the main breaker) which usually has some shielding around it to keep it separate from the other breakers, so it serves the same purpose as your disconnect. In most cases there's no point to installing an additional disconnect.Hey, stupid question time: Is it cool to install a disconnect between the meter and your main circuit breaker panel? If I had one I could disconnect power to my panel without having to call the utility! Or is that illegal for some reason?

Similar threads

- Replies

- 56

- Views

- 8K

- Replies

- 25

- Views

- 1K

- Replies

- 40

- Views

- 20K

- Replies

- 1

- Views

- 398

- Replies

- 14

- Views

- 5K