You definitely did not have to strip down to see it, or to attend the gathering poolside. In fact, a full strip down might have emptied the area for the rest of the night.Darn! I never saw this and a really wanted to (though I wanted to see MWJ's Parrot even more). I did not know I'd have to strip down to see it.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

You definitely did not have to strip down to see it, or to attend the gathering poolside. In fact, a full strip down might have emptied the area for the rest of the night.

Coming from the graffiti shirt guy.

I need a picture from 10 feet in front please......

Coming when it's installed on my car, soon.

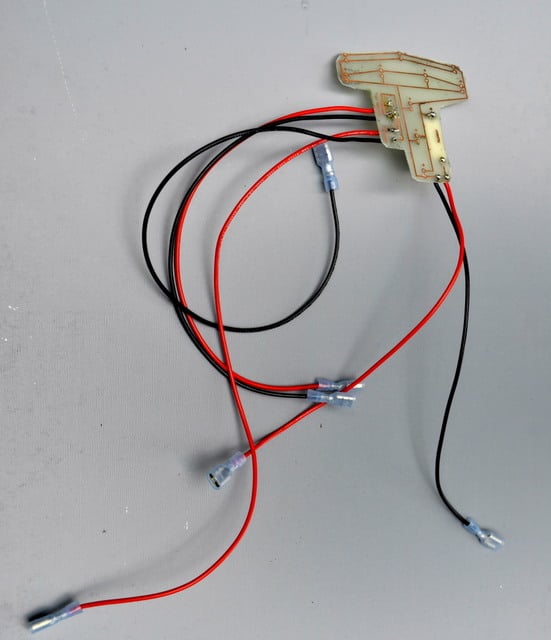

I finished making the printed circuit board last night and all of the parts are in hand so everything is ready for the installation on my Model S. I'll post photos as I go showing each step of the installation process, including assembly of the lighted T itself. Assuming all goes well the installation should be finished by Sunday and I'll post photos and video of it live on the car.

The Fury

Member

As work is progressing I thought I should post full installation instructions. I'll add photos tomorrow of all of the key parts as well as key steps.

I have everything ready for installation of the lighted T on my spare nose cone and the nose cone on the car. The holes have been drilled in the nose cone for the LED leads. Next step is to mount the T on the nose cone, finish soldering the PCB board in place, and make the power connections in the car. If all goes well, I'll get this done tomorrow.

Here are detailed instructions, along with a tool and parts/supply list. As the list suggests, this project is not for a beginner or the faint of heart

My plan looking ahead is to supply a DYI kit for those who are brave enough to take this on. The kit will include the Plexiglass T and arch, pre-drilled; the PCB; LED's and resistors; PCB screw connectors; and the two templates. All of the other part and supplies are readily available in hardware or hobby stores, so I won't supply them.

At this point I'll supply the kit free as a test to the first five owners who want to take this project on. After that I may sell the kit but I have decided that yet, as I want to see how tests go with the five owners who want to take this DYI project on. If you're interested in receiving a free test kit, please PM me. The first five PMs will get the kit.

Here are the instructions. As I said, I'll post photos of key steps tomorrow.

Installation of Model S Lighted T for nosecone

Tools needed:

· Solder gun or pencil

· Wire strippers

· Plastic lever for removing nose cone

· Dremel tool or small jigsaw

· Fine File

· Regulated 12v power supply

· 7/64’s drill bit

· Small round hobby file

· Wire crimp tool

Parts/supplies:

· Mirrored Plexiglass T and arch with pre-drilled holes for LEDs

· Ten (10) 1.8mm bright white LEDs

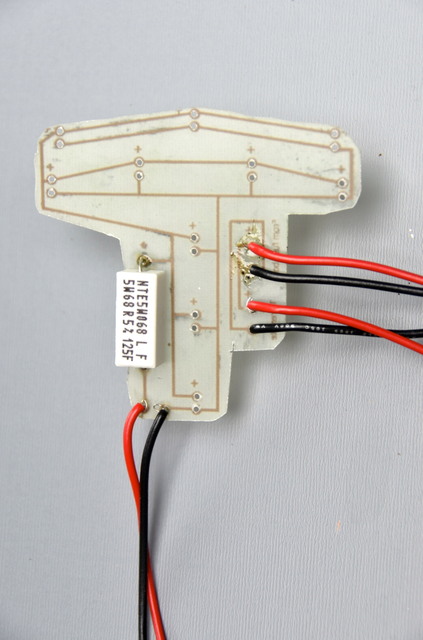

· Custom Printed Tesla T Circuit Board

· 82 ohm 5 watt resistor for PCB circuit

· 465 ohm 2 watt resister for pre-testing LEDs before assembly

· Original Tesla chromed plastic T and arch, bought separately or removed from nosecone

· Template for drilling holes in nosecone T and arch base

· Template for cutting hole in nosecone aluminum frame behind T mount

· Oznium 12V LED Dimmer and Strobe Remote Switch (12V Remote Control LED Dimmer Switch & Strobe Controller - Plug & Play)

· High quality cyanoacrylate glue (Insta-Cure+ brand recommended)

· ZAP Zip kicker CA Accelerator (for rapid cure of cyanoacrylate)

· Goop or adhesive sealant (for attaching Plexiglass T to nose cone and original Tesla chromed plastic T and arch to Plexiglass T)

· 12 feet 20 awg gauge red and black hook-up wire

· Tap-a-Fuse connector

· 5 amp fuse

Installation steps

1. Remove the nose cone from the car and take it to your work space

2. Now that you have access to the area behind the nose cone, place the template over the nose cone attachment on the aluminum nose cone frame behind the T and with a permanent marker outline its shape.

3. Using your Dremel tool, jigsaw, or other cutting tool cut the marked area out of the aluminum nose cone frame.

4. At your workspace, gently pry off the Tesla chromed T and arch with a plastic tool or old credit card. It’s affixed with double faced tape. Work carefully – it’s plastic and can be broken. When it’s off, remove any glue on the back with Good-Off or a similar tape glue remover (3M makes the best). If you purchased a new chromed T from Tesla you must remove the glue from the back. This is very important as the chrome surface provide further relection and brightness for the LEDs. This is how the new T come from Tesla. The photo below shows the double faced tape on the back that must be removed.

Then with a Dremel or other tool cut off the plastic spring clip extension on the back side of the nose cone behind the T and arch indentations. Using your Dremel tool and a small rotary file or sander remove any remainder so it’s level with the rear surface of the nose cone.

5. Lay the drilling templates over the T and arch indentations on the top center of the nose cone and mark the location of the ten holes

6. Drill the ten holes in the nosecone with the 7/64s drill. Drill the locations precisely

7. Now lay the mirrored Plexiglass T and arch face down on a flat, clean work surface

8. Test each LED before gluing them into the Plexiglass T. To do this use the 12 volt power supply with the 465 ohm 2 watt resister attached to the power lead and ground lead clipped to the cathode. Touch tehe 465 ohm 2 watt resister to the anode. The LED should light.

9. One at a time, apply a drop of cyanoacrylate into each pre-drilled hole in the back of the T and arch. Then, one at a time, spray the head of an LED with Zip Kicker (make sure no Zip Kicker sprays the LED holes) and push an LED into the hole with the anode (the longer lead, +) side oriented to the top of the T or arch. Be sure the LED leads are pointing vertically. After all of the LEDs are glued in place, check them to be sure they are secure.

10. Test the LEDs again. Using the 12 volt power supply with the 465 ohm 2 watt resister attached to the power lead, test each LED by clipping the ground lead to the cathode and the 465 ohm 2 watt resister to the anode. The LED should light.

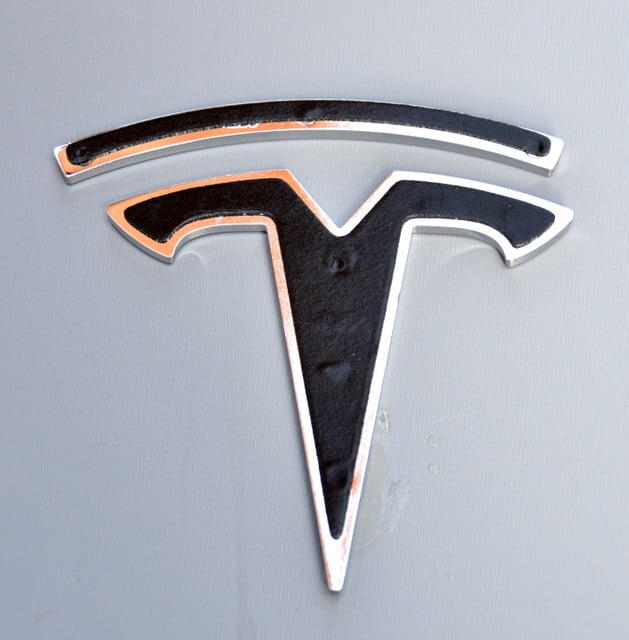

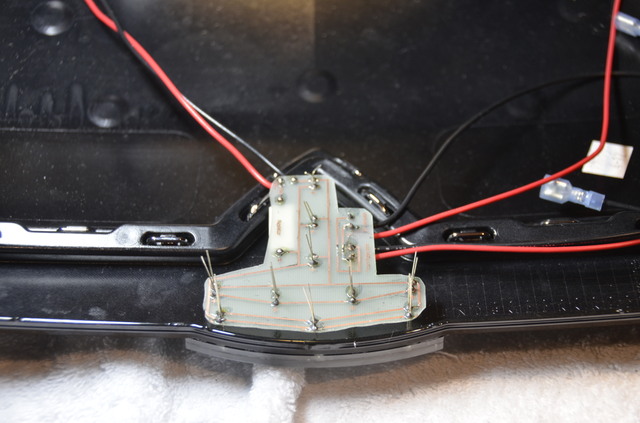

12. Thread the LED leads on the Plexiglass T and arch through the holes you drilled in nosecone, being careful not to bend and break the leads.

13. Apply very small dabs of the 3M Scotchweld 8005 to the back side of the T and arch, then them firmly into place in their respectively indentations on the nose cone and use duct tape to hold them in place until glue dries sufficiently (about an hour)

14. Solder the resistor and leads for power and the Oznium remote to the PCB board.

15. Thread the LED leads trough the corresponding holes in the PCB board but do not make any solder connections yet. As you you’ll have 20 leads to thread, this will be a bit tricky, so take your time and work slowly. This task is very frustrating, so be patient. Work from the point of the T up, inserting the long LED leads first. Use a pair of tweezers to guide the leads into their respective PCB holes.

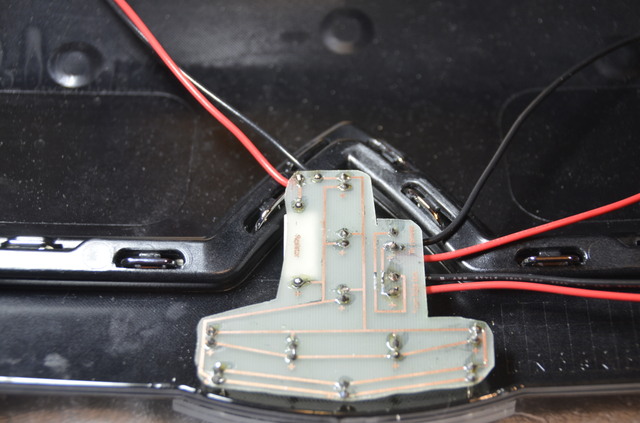

16. Then slip the PCB board down as far as it will go onto the back of the nose cone, but with out exerting excessive stress or force on the LED leads.

17. Solder all of the LED leads to their respective pads on the PCB.

18. Now make the remote control connections for the T. The connections for the Oznium ECU control box are marked on the PCB board. Attach the power input and output connections for the control box into the space connectors for these leads. Do not trim the leads on the Oxnium before making the connections – you’ll need this extra length for locating the control box on the metal cross beam behind the nose cone.

19. Locate the Tap-A-Fuse. Crimp a 6 foot piece of 20 awg red hook-up wire to the red lead.

20. Place the 5-amp fuse into one of the Tap-A-Fuse slots. Then pry off the cover to Fuse Box #x, locate and remove fuse # x, insert that fuse into the second Tap-A-Fuse slot, then insert the Tap-A-Fuse into the empty fuse slot.

21. File a small notch into the Fuse box cover for the red and black Tap-A-Fuse leads. Replace the fuse box cover with the red and black leads loosely place in the frunk.

22. Snap out the left hand side frunk plastic cover and the chrome plastic cover over the top of the nose cone frame.

23. Run the red from the Tap-A-Fuse down the left hand side of the frunk into the area behind the nose cone. Use wire ties or tape to anchor into place.

24. Place the nose cone near the car and attach the red leads to the power supply screw connector on the PCB board. Take a 3 foot section of the black 20AWG wire and attach it to the ground side of the PCB power screw connector (the other end will be attached to a ground connection in nose cone area). Make sure the connections are tight and that there’s enough slack to move the nose cone around.

25. With double faced 3M tape anchor the Oznium ECU control box to a convenient place on the metal crash bar in the nose cone area. Make sure that there’s enough slack in the controller leads to move the nose cone around.

26. Now before installing the nose cone, test operation of the lighted T by turning on the car. It should light up. Using the appropriate buttons on the remote transmitter, test the operation of the dimming, heartbeat, and strobe features. Everything should work. Now turn off the car.

27. Install the nose cone back on the car. Take care to place the PCB board carefully into the hole you cut in the nosecone frame before you snap the spring clips into place, and make sure none of the wiring is pinched. Then snap all of the nose cone spring clips in place, taking care to ensure the nose cone is firmly attached to its aluminum frame.

28. Test the T again to be sure it lights and all of the remote functions work.

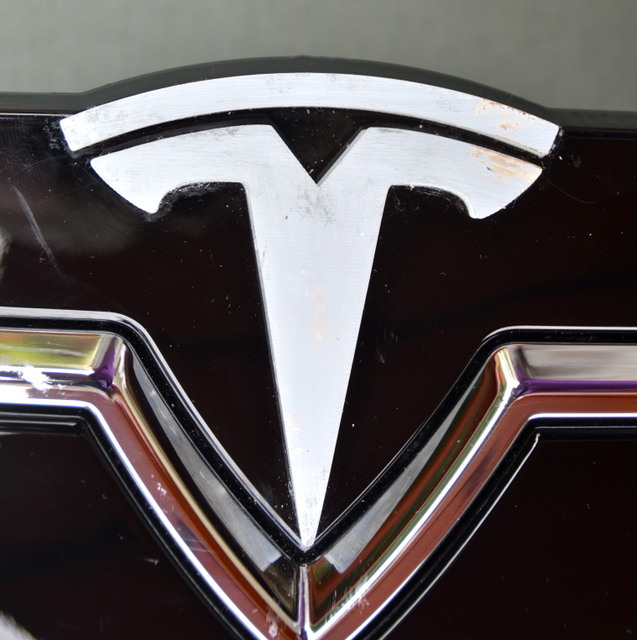

29. Finally, take the stock chromed Tesla T and arch, dab small bits of the 3M 8005 on the back of each and place carefully over the corresponding mirrored Plexgass T and arch on the nose cone. Align them carefully and tape them down for an hour so the glue can dry.

30. Enjoy your handiwork!

I have everything ready for installation of the lighted T on my spare nose cone and the nose cone on the car. The holes have been drilled in the nose cone for the LED leads. Next step is to mount the T on the nose cone, finish soldering the PCB board in place, and make the power connections in the car. If all goes well, I'll get this done tomorrow.

Here are detailed instructions, along with a tool and parts/supply list. As the list suggests, this project is not for a beginner or the faint of heart

My plan looking ahead is to supply a DYI kit for those who are brave enough to take this on. The kit will include the Plexiglass T and arch, pre-drilled; the PCB; LED's and resistors; PCB screw connectors; and the two templates. All of the other part and supplies are readily available in hardware or hobby stores, so I won't supply them.

At this point I'll supply the kit free as a test to the first five owners who want to take this project on. After that I may sell the kit but I have decided that yet, as I want to see how tests go with the five owners who want to take this DYI project on. If you're interested in receiving a free test kit, please PM me. The first five PMs will get the kit.

Here are the instructions. As I said, I'll post photos of key steps tomorrow.

Installation of Model S Lighted T for nosecone

Tools needed:

· Solder gun or pencil

· Wire strippers

· Plastic lever for removing nose cone

· Dremel tool or small jigsaw

· Fine File

· Regulated 12v power supply

· 7/64’s drill bit

· Small round hobby file

· Wire crimp tool

Parts/supplies:

· Mirrored Plexiglass T and arch with pre-drilled holes for LEDs

· Ten (10) 1.8mm bright white LEDs

· Custom Printed Tesla T Circuit Board

· 82 ohm 5 watt resistor for PCB circuit

· 465 ohm 2 watt resister for pre-testing LEDs before assembly

· Original Tesla chromed plastic T and arch, bought separately or removed from nosecone

· Template for drilling holes in nosecone T and arch base

· Template for cutting hole in nosecone aluminum frame behind T mount

· Oznium 12V LED Dimmer and Strobe Remote Switch (12V Remote Control LED Dimmer Switch & Strobe Controller - Plug & Play)

· High quality cyanoacrylate glue (Insta-Cure+ brand recommended)

· ZAP Zip kicker CA Accelerator (for rapid cure of cyanoacrylate)

· Goop or adhesive sealant (for attaching Plexiglass T to nose cone and original Tesla chromed plastic T and arch to Plexiglass T)

· 12 feet 20 awg gauge red and black hook-up wire

· Tap-a-Fuse connector

· 5 amp fuse

Installation steps

1. Remove the nose cone from the car and take it to your work space

2. Now that you have access to the area behind the nose cone, place the template over the nose cone attachment on the aluminum nose cone frame behind the T and with a permanent marker outline its shape.

3. Using your Dremel tool, jigsaw, or other cutting tool cut the marked area out of the aluminum nose cone frame.

4. At your workspace, gently pry off the Tesla chromed T and arch with a plastic tool or old credit card. It’s affixed with double faced tape. Work carefully – it’s plastic and can be broken. When it’s off, remove any glue on the back with Good-Off or a similar tape glue remover (3M makes the best). If you purchased a new chromed T from Tesla you must remove the glue from the back. This is very important as the chrome surface provide further relection and brightness for the LEDs. This is how the new T come from Tesla. The photo below shows the double faced tape on the back that must be removed.

Then with a Dremel or other tool cut off the plastic spring clip extension on the back side of the nose cone behind the T and arch indentations. Using your Dremel tool and a small rotary file or sander remove any remainder so it’s level with the rear surface of the nose cone.

5. Lay the drilling templates over the T and arch indentations on the top center of the nose cone and mark the location of the ten holes

6. Drill the ten holes in the nosecone with the 7/64s drill. Drill the locations precisely

7. Now lay the mirrored Plexiglass T and arch face down on a flat, clean work surface

8. Test each LED before gluing them into the Plexiglass T. To do this use the 12 volt power supply with the 465 ohm 2 watt resister attached to the power lead and ground lead clipped to the cathode. Touch tehe 465 ohm 2 watt resister to the anode. The LED should light.

9. One at a time, apply a drop of cyanoacrylate into each pre-drilled hole in the back of the T and arch. Then, one at a time, spray the head of an LED with Zip Kicker (make sure no Zip Kicker sprays the LED holes) and push an LED into the hole with the anode (the longer lead, +) side oriented to the top of the T or arch. Be sure the LED leads are pointing vertically. After all of the LEDs are glued in place, check them to be sure they are secure.

10. Test the LEDs again. Using the 12 volt power supply with the 465 ohm 2 watt resister attached to the power lead, test each LED by clipping the ground lead to the cathode and the 465 ohm 2 watt resister to the anode. The LED should light.

12. Thread the LED leads on the Plexiglass T and arch through the holes you drilled in nosecone, being careful not to bend and break the leads.

13. Apply very small dabs of the 3M Scotchweld 8005 to the back side of the T and arch, then them firmly into place in their respectively indentations on the nose cone and use duct tape to hold them in place until glue dries sufficiently (about an hour)

14. Solder the resistor and leads for power and the Oznium remote to the PCB board.

15. Thread the LED leads trough the corresponding holes in the PCB board but do not make any solder connections yet. As you you’ll have 20 leads to thread, this will be a bit tricky, so take your time and work slowly. This task is very frustrating, so be patient. Work from the point of the T up, inserting the long LED leads first. Use a pair of tweezers to guide the leads into their respective PCB holes.

16. Then slip the PCB board down as far as it will go onto the back of the nose cone, but with out exerting excessive stress or force on the LED leads.

17. Solder all of the LED leads to their respective pads on the PCB.

18. Now make the remote control connections for the T. The connections for the Oznium ECU control box are marked on the PCB board. Attach the power input and output connections for the control box into the space connectors for these leads. Do not trim the leads on the Oxnium before making the connections – you’ll need this extra length for locating the control box on the metal cross beam behind the nose cone.

19. Locate the Tap-A-Fuse. Crimp a 6 foot piece of 20 awg red hook-up wire to the red lead.

20. Place the 5-amp fuse into one of the Tap-A-Fuse slots. Then pry off the cover to Fuse Box #x, locate and remove fuse # x, insert that fuse into the second Tap-A-Fuse slot, then insert the Tap-A-Fuse into the empty fuse slot.

21. File a small notch into the Fuse box cover for the red and black Tap-A-Fuse leads. Replace the fuse box cover with the red and black leads loosely place in the frunk.

22. Snap out the left hand side frunk plastic cover and the chrome plastic cover over the top of the nose cone frame.

23. Run the red from the Tap-A-Fuse down the left hand side of the frunk into the area behind the nose cone. Use wire ties or tape to anchor into place.

24. Place the nose cone near the car and attach the red leads to the power supply screw connector on the PCB board. Take a 3 foot section of the black 20AWG wire and attach it to the ground side of the PCB power screw connector (the other end will be attached to a ground connection in nose cone area). Make sure the connections are tight and that there’s enough slack to move the nose cone around.

25. With double faced 3M tape anchor the Oznium ECU control box to a convenient place on the metal crash bar in the nose cone area. Make sure that there’s enough slack in the controller leads to move the nose cone around.

26. Now before installing the nose cone, test operation of the lighted T by turning on the car. It should light up. Using the appropriate buttons on the remote transmitter, test the operation of the dimming, heartbeat, and strobe features. Everything should work. Now turn off the car.

27. Install the nose cone back on the car. Take care to place the PCB board carefully into the hole you cut in the nosecone frame before you snap the spring clips into place, and make sure none of the wiring is pinched. Then snap all of the nose cone spring clips in place, taking care to ensure the nose cone is firmly attached to its aluminum frame.

28. Test the T again to be sure it lights and all of the remote functions work.

29. Finally, take the stock chromed Tesla T and arch, dab small bits of the 3M 8005 on the back of each and place carefully over the corresponding mirrored Plexgass T and arch on the nose cone. Align them carefully and tape them down for an hour so the glue can dry.

30. Enjoy your handiwork!

Last edited:

MissErol

Model S #9221

I'd love to take this on! How did you get a spare node cone? I'd really rather do it on a spare one as well. How much did it cost?

pgiralt is #1

npiwovar is #2.

nkohlimd is #3

zax 123 is #4

SUPRKAR is #5

No slots left.

After the tests are done, and assuming they're successful, I'll provide more kits.

Last edited:

All of the 5 spots for the test kits have been taken. It will take two weeks to prepare and ship them. I will send complete installation instructions with the kits. I'm hoping the five owners who receive the test kits will post their installation experiences and comments here. The idea is to make improvements in both the ease of installation and the kit itself.

BTW, the chromed plastic Tesla T has a slight curvature in it to fit the profile of the nose cone. The Plexiglass T provided in the kits will have the same curvature so the original T fits over it as perfectly as possible.

Now to finish my install.

BTW, the chromed plastic Tesla T has a slight curvature in it to fit the profile of the nose cone. The Plexiglass T provided in the kits will have the same curvature so the original T fits over it as perfectly as possible.

Now to finish my install.

pgiralt is #1

npiwovar is #2.

nkohlimd is #3

zax 123 is #4

SUPRKAR is #5

No slots left.

After the tests are done, and assuming they're successful, I'll provide more kits.

Thanks to the 5 Beta testers!

The Fury

Member

No photos showing yet?

Check post #109. The photos are there.

I'm totally interested in the "kit+" offering, since I suspect the retrofit will be relatively spendy.All of the 5 spots for the test kits have been taken. ... The idea is to make improvements in both the ease of installation and the kit itself.

Too soon? (Reference to Perf+.)

Thanks for the photos. I was planning on taking some photos during my beta test but looks like you already beat me to it.I've added photos to the installation instructions below. As work progresses on my install I'll continue to add more.

Similar threads

- Replies

- 166

- Views

- 7K

- Replies

- 0

- Views

- 735

- Replies

- 13

- Views

- 6K

- Replies

- 11

- Views

- 5K

- Replies

- 3

- Views

- 1K