OP, you're gonna have a b!tch of a time hooking up your HPWC to 4 gauge.

I've got a ~60 foot run of 2x 6awg hots + 1x 10awg ground THHN in a 3/4" rigid PVC conduit behind drywall, I'm OCD like that, wanted a clean install. Heat is of no concern. There are fill tables for heat/gauge/conductors/amperage/length etc and I'm within code for my application.

Snag the THHN off eBay and the 3/4 rigid PVC and all the misc unions, cable protectors, pvc clamps, fire insulation foam etc @ HomeDepot/Lowes.

Code allows only so many bends in your run so be sure to factor that in. Get a fish from Harbor Freight for cheap (or HD/Lowes). Don't forget conduit lube to help with the fish. Oh and a heat gun if you need to persuade the PVC into a gentle curve or what not.

Don't forget you'll probably need to get it inspected by our county inspector to be legal/insurance. Mine was like a $40 application fee.

*I am not a licensed electrician, do your own research. County inspector however did like my work and passed me. I guess he was used to some janky arse installs from other people though.

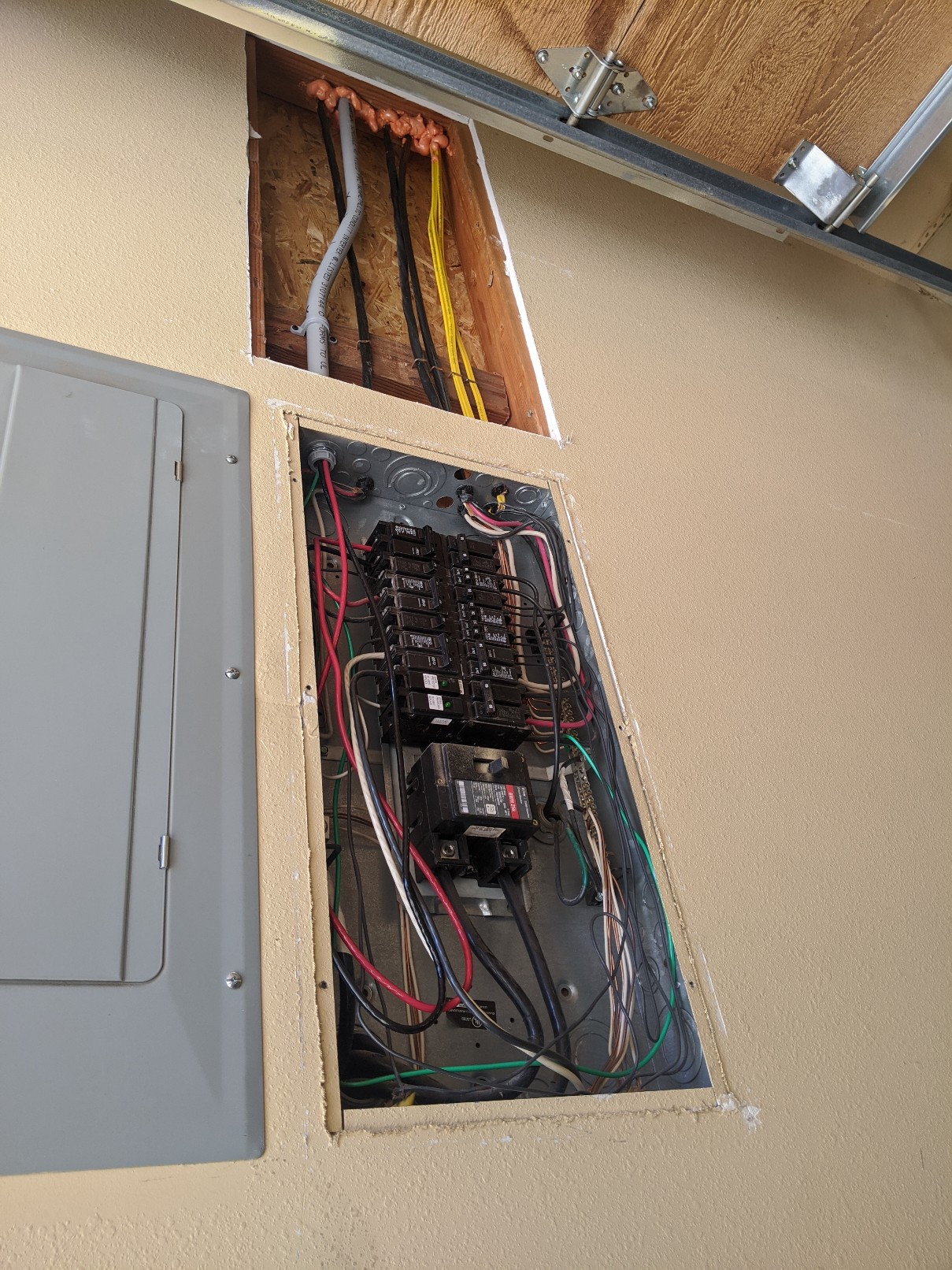

Here you can see my install with the orange fire retardant foam going thru the header. I did that little jog over in the conduit to use an existing hole in the header, previous home owner was a wood worker and had 240v runs going to the ceiling to drop down to power his various equipment. I gave myself some extra slack incase I ever wanna do a branch to go power another HPWC off the same circuit, while of course using the connectivity / power share functionality so both HPWC won't draw more than 48a at a time. Now I just need to get the wife onboard to go fully electric