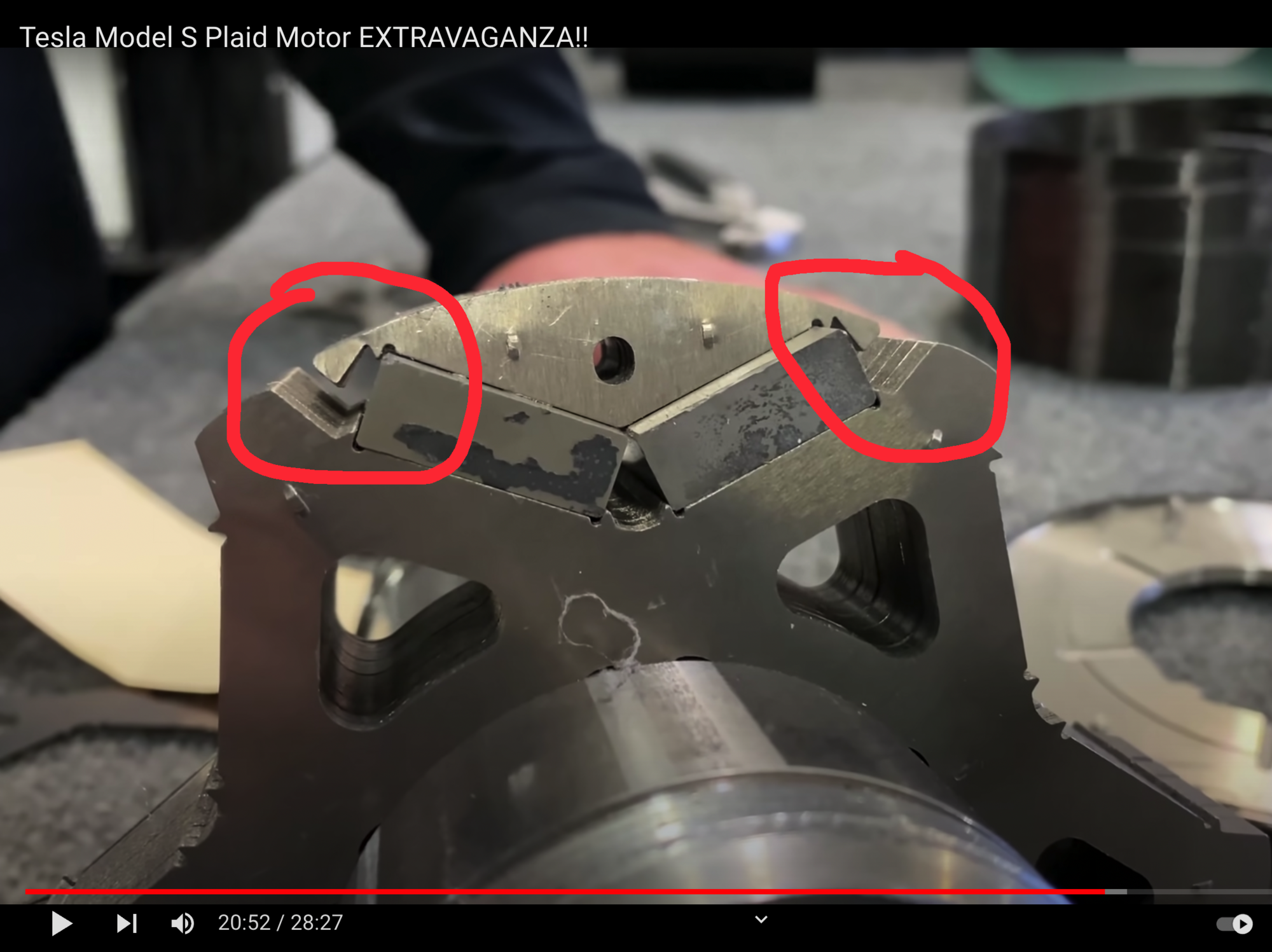

Sandy has a great video (as usual) on the Plaid motors. They make the claim in this video that introducing this specific design change, allows Tesla to pull an additional 25% HP, and 25% TQ from the motors. I'm making an assumption here, but having this small segmentation on both ends is probably also why they were forced to do the carbon fiber winding, to hold it all together (but could be wrong on that).

If this is the actual statistic on performance increases, Tesla could easily add an extra 100hp/tq to the model 3 by doing that to both motors, and then use whatever controller voodoo they implemented on the plaid to hold that power out to the end of the RPM band. Seems like a minimal cost, would give us a massive boost in performance, and would still remain well below the plaid's performance to not infringe on those sales.

It's hard to believe such a small change, makes such an enormous difference in performance.

If this is the actual statistic on performance increases, Tesla could easily add an extra 100hp/tq to the model 3 by doing that to both motors, and then use whatever controller voodoo they implemented on the plaid to hold that power out to the end of the RPM band. Seems like a minimal cost, would give us a massive boost in performance, and would still remain well below the plaid's performance to not infringe on those sales.

It's hard to believe such a small change, makes such an enormous difference in performance.