By my math, while lifting I am about 30% below the stress required to cause permanent deformation of the longitudinal beams (permanent deformation being even, say, 1mm of permanent bend), but significantly below the point of mechanical failure. Of course, stress goes to near zero once the jack stands are in place.

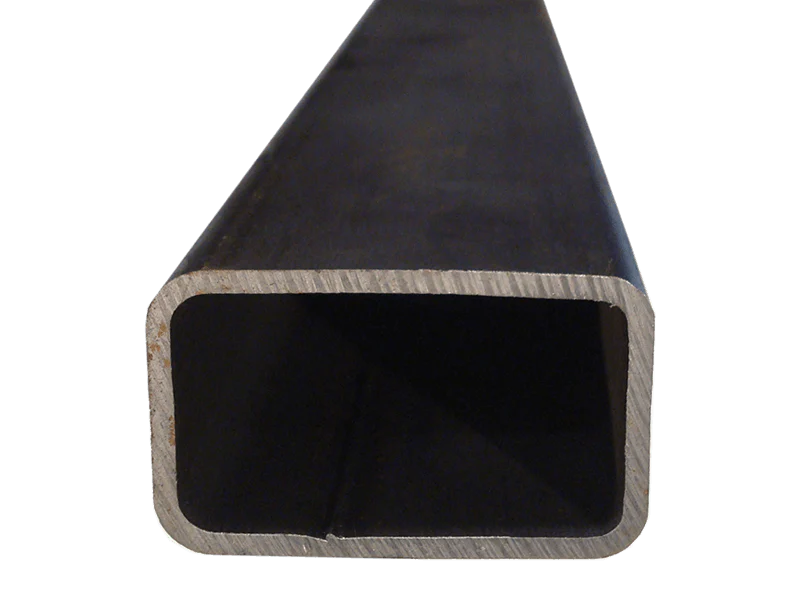

I made it out of 3x3 Hot Rolled Square tubing with 0.120” walls, with all joints seams double-welded. A 20’ stick was $170, and I already had the jack.

(Oh, I’m installing lowering springs and painting the wheels

Why? Because I could