Ok. I went and got more DATA. Like a real EE will do, instead of using a "simple voltmeter" to find the peak, I used an oscilloscope (that I designed myself when I worked at a T&M company) to look at the signal going to the EPB motor.

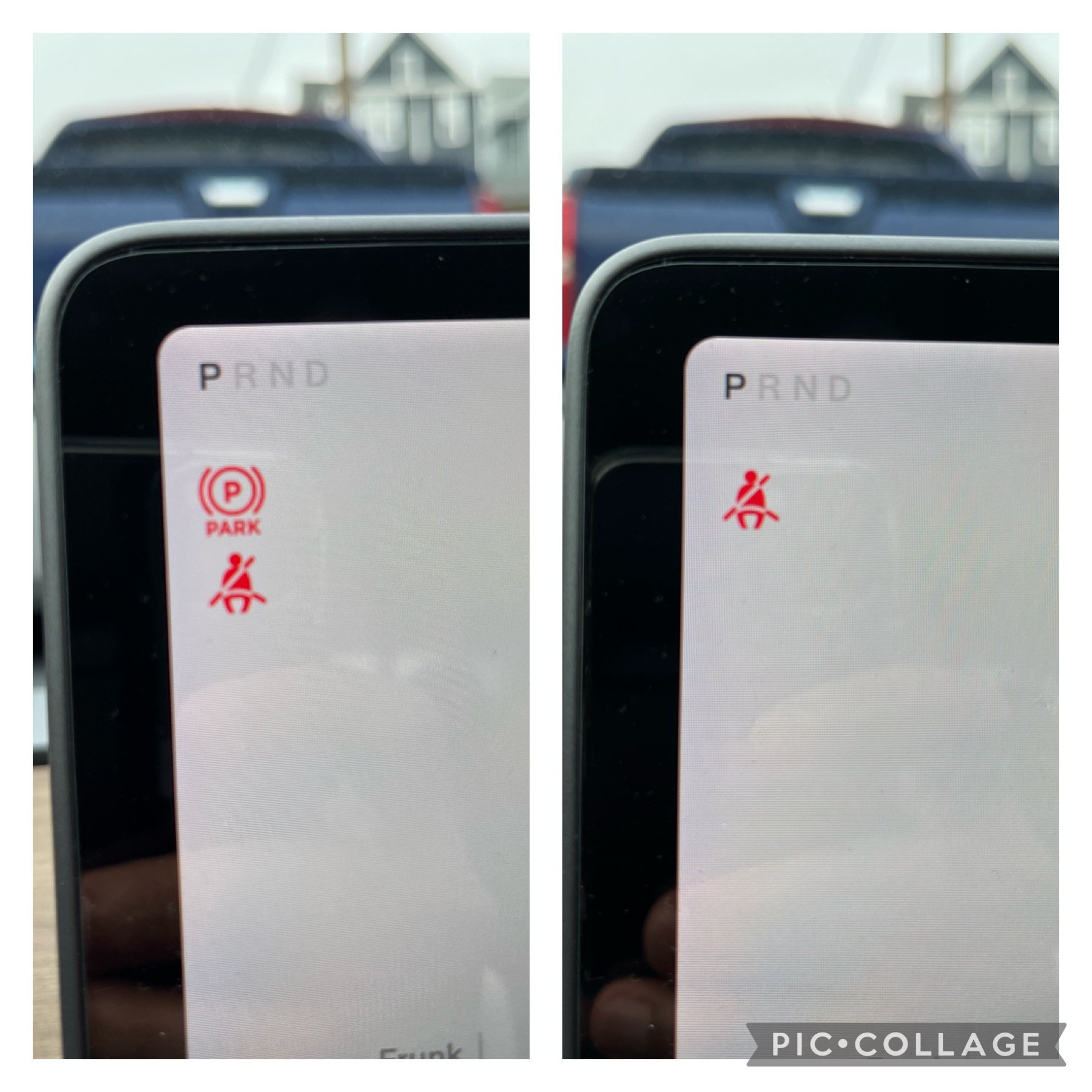

It's complicated. Here's what the trace looks like. The first section is the retract, the second is an activation using park.

(Can you imagine trying to diagnose this with a peak hold voltmeter!???)

Those are NOT PWM pulses. There is 3.0 seconds between the start of the retract and the end of the apply. Every pulse is 14ms on and 3ms off, and they don't change in duty cycle or frequency at any point. The first and last ones are the exact same timing, Plus, 17ms is only 58Hz, which is way too slow for any kind of useful PWM current control.

I'll admit, I don't exactly know what is going on here, but I have a theory. They are sensing the *speed* of the motor using back-EMF. They run the motor for 14ms at full bus voltage. They then turn off the drive and check the back EMF voltage to sense RPM. You can see that during the retract, the beginning has a low voltage signature until it starts spinning, and the clamp has a low voltage signature when at the end when it comes to a stop. Also, look at the signature as it retracts and runs down at the end as it slows to a stop (but thinking about back EMF is just brining quantum mechanics into a simple, low speed, brushed DC motor, amiright?)

I tried to do this in current mode as well, but when I put the current shunt I had inline, it messed up the whole logic. The motor would run WAY longer, and when it clamped, it wouldn't detect the clamp had happened. The system would peak at over 15A, and actually melted one of my wires. It might eventually time out, but I never let it, I always yanked a wire. I'm sure with a really nice setup with custom harnesses and a very small shunt you could make this measurement, but all I have right now is jamming wires into some connectors since I don't have the mates. It is possible they are *also* doing current control within these pulses. But the question remains, why bother to pulse unless you are doing something interesting in the off time? Also, why does it peak at >15A if there is closed loop current control when normal operations are under 5A?

My theory is that the RPM is a much more stable signal than current or anything else. For instance, the back EMF wouldn't be impacted by temperature, since it's a zero current state and the change in copper resistance would be irrelevant.

I'll go out later and get these clamp traces in the 3 different activation modes and we can see if they look any different.