For the past few days, I've spent more time than I wish to upgrade the brakes on my P3. The biggest reason for the time suck is due to a lack of necessary information on how to service the car. For the benefit of the community and my ever forgetful memory, I will document my brake related journeys here.

The plan was to have a Mrs. approve or unnoticeable upgrades that increase the capability for HPDE events. The setup I decided to go with is the Racing Brake 380mm BBK with 4-pots caliper for the front, for the rear Racing Brake 2-piece rotor. I order these parts in January, finally got the parts in April. This first post will be on the front BBK install. The rear rotor RB sent me does not fit P3, so I am working with RB to resolve this soon.

The RB front BBK is a great kit. It comes with a complete set of front, and rear stainless line, which I'm 99% sure is by the same manufacturer for the SS line MPP offers. I didn't know RB would include the rear lines as well, so in advance, I purchase a set from MPP. MPP SS lines have a blue plastic/rubber coating, while RB has no coating, just raw SS. If anyone is interested in a set of SS line for their Model 3/P3 DM me for a deal.

Model 3/P3 front caliper is 4-pots, due to the shape the maximum rotor these can accommodate is 365mm. So new caliper is required when going to 380mm rotor. RB has an option for 6-pots caliper for P3 upgrade that is part of their X/S upgrade kit; for me, it will most likely violate the Mrs. rule.

The numbers:

RB caliper - 4.728kg (-0.664kg)

P3 caliper - 5.392kg

RB rotor - 380x32mm, 10.446kg (1.654kg)

P3 rotor - 355x25mm, 8.792kg

Net weight gain - 0.99kg, 2.178lb per side.

The preparation:

- Read through MPP BBK instruction multiple times, it is quite good - MPP Page Mill 365mm Big Brake Kit Instructions

- Have zip tie ready to hang up the stock caliper before complete removal

- Paper towel for wiping up brake fluid

- Remove the cap of the brake master cylinder reservoir to alleviates the pressure in the system for pushing piston/pads into the caliper.

- Loosely secure the SS brake line to the new caliper

- Get a 11/12mm brake line wrench, these will be used for the nut on the brake fluid hard line. You don't want to strip this with a regular open end wrench, brake fluid makes everything slippery.

The instruction: (all torque numbers are for your reference)

- Remove the stock caliper by removing the two bolts on the back side. I notice by feeling the torque of the stock bolts from the factory felt a lot less than the 77lb/ft called out in the MPP instruction

- Slide the caliper off and hang the lower control arm or where ever that will not cause a pull on the brake line

- Remove the rotor

- Remove the dust shield. Reinstall the three Torx bolts with some weak Loctite back onto the control arm. I tend to lose small things or forget what they were for, doing so help met avoid these two problems.

- Install the RB rotor onto the hub. Use the small stock bolt to hold the rotor in place

- Slide caliper onto the rotor, secure the caliper using the two stock bolts. Referencing Bentley service manual for other cars of similar brake bolt sizes I decided to reduce these bolts to 70lb/ft which is slightly lower than MPP spec but still feels tighter than stock. Will check on these bolts after some miles.

- Install the SS line bracket onto the suspension arm, do not tighten this now so the twist of the line could be adjusted once both ends of the line is connected

- Liberally spray the connector and perch where the stock rubber line is connected to the hard line. Make sure there is no sand and other object on the perch and connector.

- Use a pier to pull off the connector retaining clip

- This next few steps requires quickness to minimize amount of brake fluid mess. I like to place a box with peper towels underneath the car to catch dripping brake fluid

- Break the torque on the brake line connector, 1/2 turn is all you need to get the nut loose enough for finger turning the rest of the way

- Connect the new SS line to the hardline, hand tightening it until the two parts meet

- With both side of the new SS brake line still lose, adjust the twist of the line so it would allow movement without rubbing other parts for the entire suspension travel. Once the twist and position of the line is deemed acceptable, tighten both ends of the SS line. There is no torque spec on these, I go by feel, which end up roughly being 1/16 ~ 1/8 turn after the parts touch.

- Clean off the brake fluid

- Install the retaining clip

- Now repeat on the other side

- Bleed the system once booth side are installed

Hello big boys. The mounting bracket is preinstalled by RB.

Well worth the money.

Yep, that is a dust shield on a Tesla. Note the stock caliper hanging there with a ziptie.

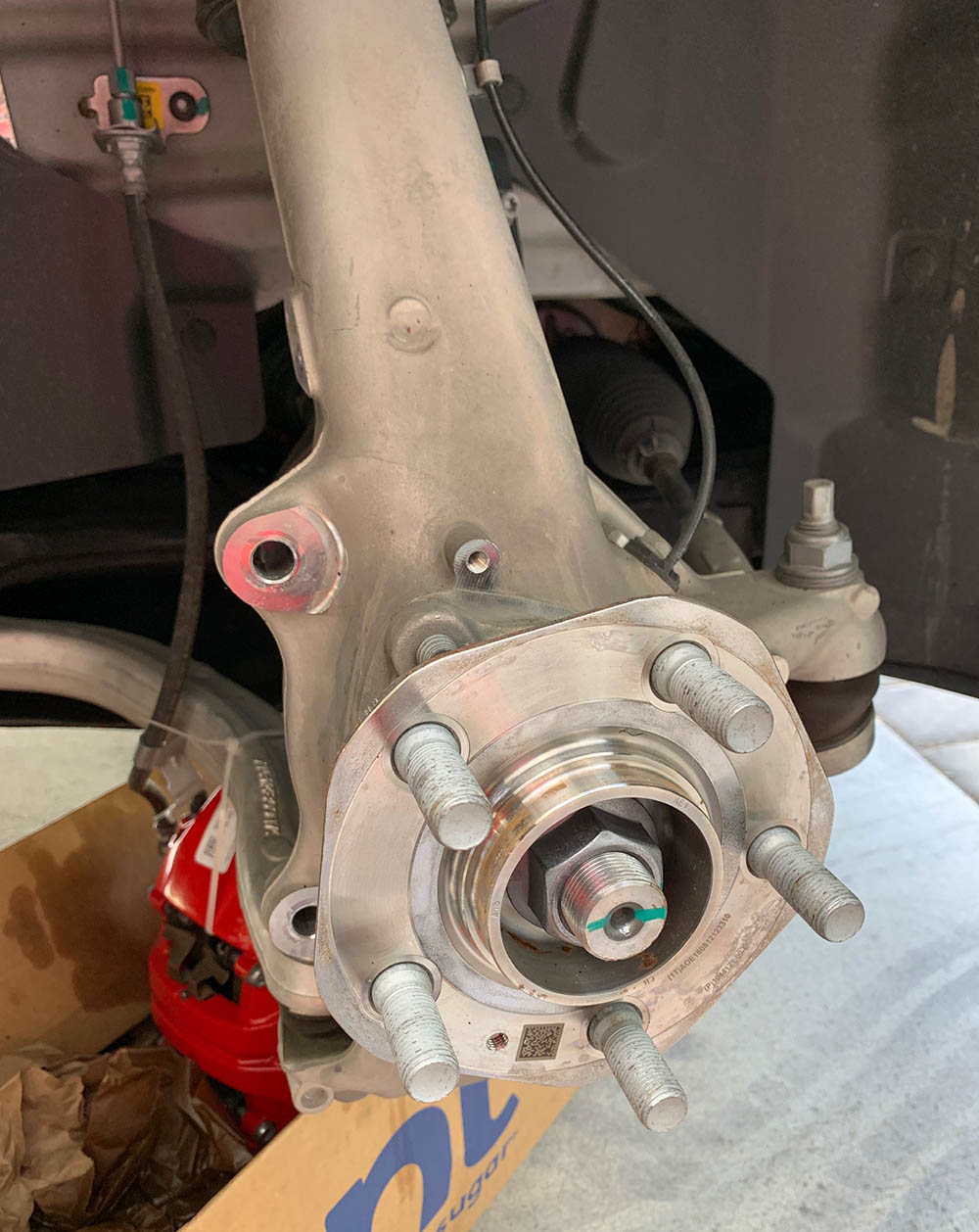

Naked hub

380mm pizza pie

It is hard to see in this photo, but the rotor is dead center of the caliper.

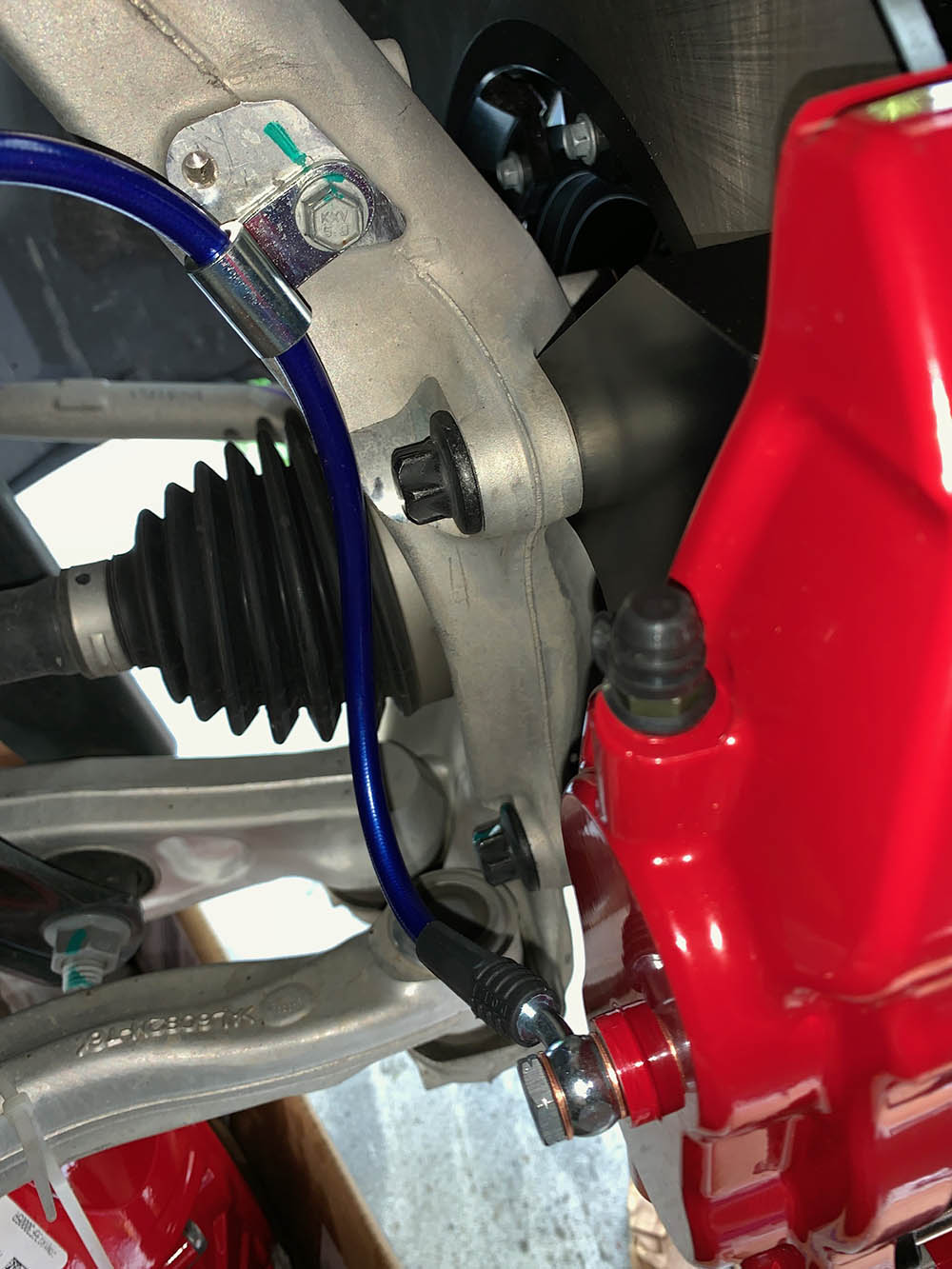

Routing of the brake line. There is actually +2" of air between the brake line and the CV boot.

Hello, MPP blue SS lines.

One side is done.

Plenty of clearance between caliper and wheel barrel of 19x9" VS Forged VS16.

The plan was to have a Mrs. approve or unnoticeable upgrades that increase the capability for HPDE events. The setup I decided to go with is the Racing Brake 380mm BBK with 4-pots caliper for the front, for the rear Racing Brake 2-piece rotor. I order these parts in January, finally got the parts in April. This first post will be on the front BBK install. The rear rotor RB sent me does not fit P3, so I am working with RB to resolve this soon.

The RB front BBK is a great kit. It comes with a complete set of front, and rear stainless line, which I'm 99% sure is by the same manufacturer for the SS line MPP offers. I didn't know RB would include the rear lines as well, so in advance, I purchase a set from MPP. MPP SS lines have a blue plastic/rubber coating, while RB has no coating, just raw SS. If anyone is interested in a set of SS line for their Model 3/P3 DM me for a deal.

Model 3/P3 front caliper is 4-pots, due to the shape the maximum rotor these can accommodate is 365mm. So new caliper is required when going to 380mm rotor. RB has an option for 6-pots caliper for P3 upgrade that is part of their X/S upgrade kit; for me, it will most likely violate the Mrs. rule.

The numbers:

RB caliper - 4.728kg (-0.664kg)

P3 caliper - 5.392kg

RB rotor - 380x32mm, 10.446kg (1.654kg)

P3 rotor - 355x25mm, 8.792kg

Net weight gain - 0.99kg, 2.178lb per side.

The preparation:

- Read through MPP BBK instruction multiple times, it is quite good - MPP Page Mill 365mm Big Brake Kit Instructions

- Have zip tie ready to hang up the stock caliper before complete removal

- Paper towel for wiping up brake fluid

- Remove the cap of the brake master cylinder reservoir to alleviates the pressure in the system for pushing piston/pads into the caliper.

- Loosely secure the SS brake line to the new caliper

- Get a 11/12mm brake line wrench, these will be used for the nut on the brake fluid hard line. You don't want to strip this with a regular open end wrench, brake fluid makes everything slippery.

The instruction: (all torque numbers are for your reference)

- Remove the stock caliper by removing the two bolts on the back side. I notice by feeling the torque of the stock bolts from the factory felt a lot less than the 77lb/ft called out in the MPP instruction

- Slide the caliper off and hang the lower control arm or where ever that will not cause a pull on the brake line

- Remove the rotor

- Remove the dust shield. Reinstall the three Torx bolts with some weak Loctite back onto the control arm. I tend to lose small things or forget what they were for, doing so help met avoid these two problems.

- Install the RB rotor onto the hub. Use the small stock bolt to hold the rotor in place

- Slide caliper onto the rotor, secure the caliper using the two stock bolts. Referencing Bentley service manual for other cars of similar brake bolt sizes I decided to reduce these bolts to 70lb/ft which is slightly lower than MPP spec but still feels tighter than stock. Will check on these bolts after some miles.

- Install the SS line bracket onto the suspension arm, do not tighten this now so the twist of the line could be adjusted once both ends of the line is connected

- Liberally spray the connector and perch where the stock rubber line is connected to the hard line. Make sure there is no sand and other object on the perch and connector.

- Use a pier to pull off the connector retaining clip

- This next few steps requires quickness to minimize amount of brake fluid mess. I like to place a box with peper towels underneath the car to catch dripping brake fluid

- Break the torque on the brake line connector, 1/2 turn is all you need to get the nut loose enough for finger turning the rest of the way

- Connect the new SS line to the hardline, hand tightening it until the two parts meet

- With both side of the new SS brake line still lose, adjust the twist of the line so it would allow movement without rubbing other parts for the entire suspension travel. Once the twist and position of the line is deemed acceptable, tighten both ends of the SS line. There is no torque spec on these, I go by feel, which end up roughly being 1/16 ~ 1/8 turn after the parts touch.

- Clean off the brake fluid

- Install the retaining clip

- Now repeat on the other side

- Bleed the system once booth side are installed

Hello big boys. The mounting bracket is preinstalled by RB.

Well worth the money.

Yep, that is a dust shield on a Tesla. Note the stock caliper hanging there with a ziptie.

Naked hub

380mm pizza pie

It is hard to see in this photo, but the rotor is dead center of the caliper.

Routing of the brake line. There is actually +2" of air between the brake line and the CV boot.

Hello, MPP blue SS lines.

One side is done.

Plenty of clearance between caliper and wheel barrel of 19x9" VS Forged VS16.