I appreciate the feedback on the age of the pack. So it seems like even though this one was a factory refurbished unit in 2021, they are effectively recycling the pack housings all the way back from 2012-2013 timeframe up to current models w/ refurbished cell assemblies. At this point I would assume it does not have the improved vent design if they are just swapping new modules in and out of a pack. Is there anything I can do in terms of a temporary seal (e.g. caulk, weatherized adhesive tape, etc) on the bottom of the pack to help keep moisture out of it? I can see what looks like fresh caulking on the front of the pack where it's screwed together in the frunk. I don't know if the moisture is entering from underneath the car or it's just an issue of moisture in the air getting between the pack and the car. I see what looks like a gore vent in the middle of the penthouse of the pack and it looks new. Thank you for the updates.Cool!

Judging by the color of the front hump that is a very old battery pack. I've only seen that color casing on some of the earliest packs. I'd bet this doesn't have updated anything except maybe contactors and fuse.

Tesla's not going to know or tell you if it has updated vents... in fact, the people at the service centers don't seem to have a clue what is done to refurbish them once they're sent off for it.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vendor Preventative Maintenance regarding Battery Failures in early Model S vehicles (2012-2014)

- Thread starter wk057

- Start date

They changed the design of the side vents significantly (theres 2 instead of 6 or 8 now) and the material is better. The top is sealed differently. The fuse isn't on the top. Bunch of small improvements that add up.

I've got a March 2016 (nosecone) S 90D

I recently had my S in for service because the AC box was dripping water into the cabin -- the AC condensate drain had plugged.

They had the car for more than a week and explained that they had to drop the battery to clear out the drain pipe, and said they had moved the drain location to make it easier to clear out in the future. (I got the car in 2019 when tesla was offering the 4 year bumper to bumper warranty which will be intact until june of 2023, thankfully...)

So -- it seems like even the late pre facelift cars have the silly location for the drain exit. I haven't looked around for it but hopefully it doesn't dump onto the top of the battery (which is nuts).

Do you have any views of which battery generations are subject to moisture intrusion? Were the later 85 and all the 90 (and the smaller versions of the same) battery packs updated to tolerate the water torture treatment?

dark cloud

Active Member

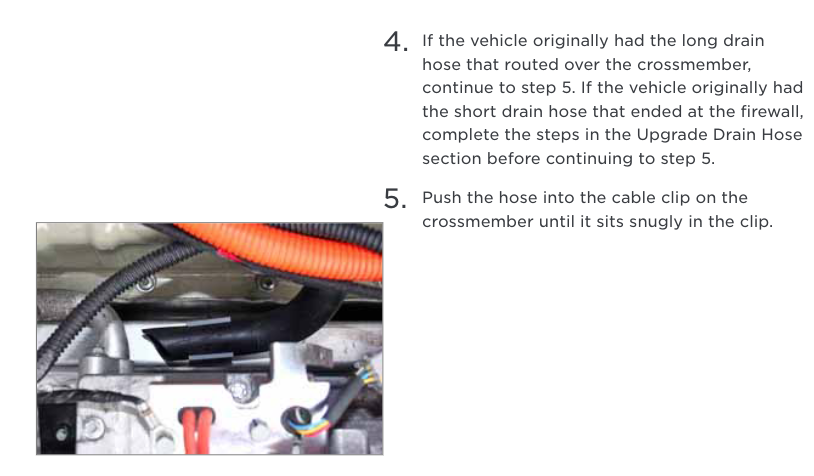

I couldn't find a service bulletin for updating the drain hose, but did find this service bulletin from Dec 2015 where it explains correcting a "misrouted" or kinked hose; not a mention of updating a short hose, but it shows a good picture of what I assume is the current correct and updated exit position:

Can you confirm @wk057 , is this okay? It exits on the cross member but it looks like condensate can still puddle at the front of the HV BMS cover.

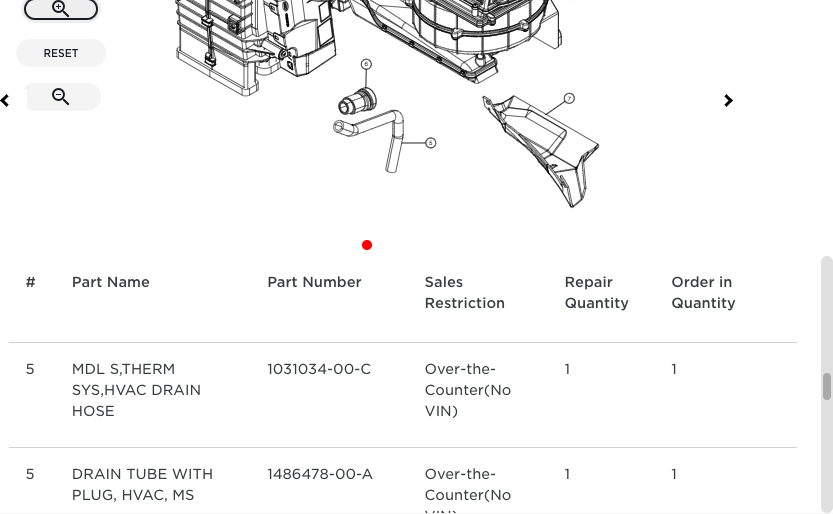

However, in the service manual it does describe an updating of the drain hose, only for the non-dual motor 2012-2020 model S's.: For the dual motor procedure this is not mentioned.

Does this mean all dual motor Model S have had their HVAC drain hoses updated?

Lastly, I thought it best to buy the updated hose from Tesla parts if someone else were inclined to fix this issue, and I assume the part number is the "updated" longer hose, but in the picture it sure looks like the short hose ?

Can you confirm @wk057 , is this okay? It exits on the cross member but it looks like condensate can still puddle at the front of the HV BMS cover.

However, in the service manual it does describe an updating of the drain hose, only for the non-dual motor 2012-2020 model S's.: For the dual motor procedure this is not mentioned.

Does this mean all dual motor Model S have had their HVAC drain hoses updated?

Lastly, I thought it best to buy the updated hose from Tesla parts if someone else were inclined to fix this issue, and I assume the part number is the "updated" longer hose, but in the picture it sure looks like the short hose ?

dark cloud

Active Member

Amazing that this post suggests some service centres/techs were aware of the issue, and have proactively corrected it, yet 5 years later others are unaware, or choose to overlook/ignore it............. So it seems like even though this one was a factory refurbished unit in 2021, ....

Cars after Q1'15 all should have the better drain routing.

However, on dual motor cars it's actually easier to remove the battery pack to access many of the components near the firewall area than it is any other way... so removing the pack to do something like this isn't surprising.

There's no reason to remove the frunk for a pack swap. Nothing is attached to the top of the pack itself there, and anything odd is easily spotted from below.

I'm not 100% sure on the official parts situation for this particular tube.

However, on dual motor cars it's actually easier to remove the battery pack to access many of the components near the firewall area than it is any other way... so removing the pack to do something like this isn't surprising.

There's no reason to remove the frunk for a pack swap. Nothing is attached to the top of the pack itself there, and anything odd is easily spotted from below.

I'm not 100% sure on the official parts situation for this particular tube.

Last edited:

Cars after Q1'15 all should have the better drain routing.

However, on dual motor cars it's actually easier to remove the battery pack to access many of the components near the firewall area than it is any other way... so removing the pack to do something like this isn't surprising.

There's no reason to remove the frunk for a pack swap. Nothing is attached to the top of the pack itself there, and anything odd is easily spotted from below.

I'm not 100% sure on the official parts situation for this particular tube.

With the newer style battery packs (later 85 / 90 and related smaller packs) is dripping water on them constantly as much of an issue as it was with the older style packs?

The newer packs have a slightly better setup at the top for preventing water from getting to places where it could be a problem. Not 100% perfect, but likely good enough that it won't be a problem unless you're just continuously soaking it or something.

This is definitely a priority project, because I think catching and mitigating these issues as early as possible is going to be a better long term plan than trying to correct them after the fact. Unfortunately we've got so many concurrent projects for upcoming products going on at the moment, and our project budget is actually stretched pretty thin on both manpower and funding right now because of everything that's needed and the rapidly rising costs of a lot of aspects of doing business in general. I'm probably going to end up looking into some outside investment to get this particular project, and possibly some others, over the finish line sooner, rather than later or not at all. Right now a huge chunk of project funds are sunk into our custom pack replacement project, and we've been trying to keep as much of this in-house as possible figuring this would be a good way to keep the final cost-to-customer as low as possible, but we might need to rethink some things in order to actually get some of this stuff out the door in a reasonable time. Not really 100% sure how best to approach any of that at the moment, however, so still up in the air.

This is definitely a priority project, because I think catching and mitigating these issues as early as possible is going to be a better long term plan than trying to correct them after the fact. Unfortunately we've got so many concurrent projects for upcoming products going on at the moment, and our project budget is actually stretched pretty thin on both manpower and funding right now because of everything that's needed and the rapidly rising costs of a lot of aspects of doing business in general. I'm probably going to end up looking into some outside investment to get this particular project, and possibly some others, over the finish line sooner, rather than later or not at all. Right now a huge chunk of project funds are sunk into our custom pack replacement project, and we've been trying to keep as much of this in-house as possible figuring this would be a good way to keep the final cost-to-customer as low as possible, but we might need to rethink some things in order to actually get some of this stuff out the door in a reasonable time. Not really 100% sure how best to approach any of that at the moment, however, so still up in the air.

maximizese

Member

I share in your amazement. In Jan 2019, I bought a used 11/13 built S 85 from Tesla with just under 60K miles on the odometer with the 2yr/up to 100K mile warranty. 12/28, I got a number of faults like:Amazing that this post suggests some service centres/techs were aware of the issue, and have proactively corrected it, yet 5 years later others are unaware, or choose to overlook/ignore it.

- Service required, car may not restart

- Systems performance check upon reboot

- Regenerative braking system disabled

- Top speed and acceleration reduced

- Replace Bolts in Steering Rack Housing and Apply Wax Sealant

- 12V Battery Replaced

- Drive Unit - Rear - Large replaced (G-48 coolant, side motor mount, 1015176-00Q, ASY HV Cover, Inverter)

- Pack Contactors Updated & Replaced (Pyro Fuse, HVAC drain hose, CAP Vent, ASY Harness HV Sense, Breather Inverter Motor)

As for the physical battery health inspection, I look forward to learning more and hopefully can see some pictures of what appears to be acceptable and what looks like a deeper inspection would be recommended. Moisture ingress seems like a big concern if a trend is detected. Seems like Tesla would have the most information and I'm doubtful they will share it. I wonder what the problem is: the sealant materials, sealant application, thermal/physical stress of the battery case, etc. Makes me want to dump a bunch of desiccant around the battery case and seams

As for the physical battery health inspection, I look forward to learning more and hopefully can see some pictures of what appears to be acceptable and what looks like a deeper inspection would be recommended. Moisture ingress seems like a big concern if a trend is detected. Seems like Tesla would have the most information and I'm doubtful they will share it. I wonder if its the sealant materials, sealant application, thermal/physical stress of the battery case, etc the is the problem. Makes me want to dump a bunch of desiccant around the battery case and seams

The sealant itself hasn't changed much at all since the beginning. It's pretty solid stuff.

The issue seems to be areas around the older fasteners, the top-type fuse cover, and the way the fire blanket is mounted on older packs which doesn't allow water that gets into readily leave or evaporate. In fact, we've gotten a car from the Las Vegas area that basically had a puddle on top of the battery pack under the fire blanket, with all of those fasteners mostly rusted through.

Tesla seals some fasteners with o-rings, which don't make great seals once the fastener itself or the pack cover corrodes/rusts around it from moisture.

They mitigate this a bit on newer packs by using a s***-ton (official engineering term, of course) more sealant around the inside areas where fasteners are placed... which does help, but the best improvements have been in keep moisture away from them in the first place and/or allowing any moisture that does get near them to evaporate normally.

Then there's the side vents. Older packs have somewhere around 100 of these plastic/rubber pressure vents... any one of which can fail and allow humid air inside the pack, which will condense at some point and cause problems. The older vent styles also tend to be able to be overcome by some bugs and the like, creating spots for moisture.

Rodents also seem to like the older fire blanket setup, as they can access the edges of it from the under-frunk area and chew off chunks of the rubber seal and part of the ceramic blanket material, causing more problems.

The vast majority of issues were corrected or decently mitigated by mid 2015 on both the vehicle and pack side of things, but none of them really made it back to older vehicles.

Continuing some thoughts:

A core issue with this service is that it's just not going to be practical for all of the people who want or need it to get their vehicles to 057 for service, so there's going to definitely need to be a way to do this that's more local to the customers. Combine that with tech throughput (we could probably do 5 of these per day with a dedicated tech pair), and to even address 1% of the potential ~70,000 vehicles in this group, would take years.

So I've put in some work on a plan to be able to do this using... well, let's just say that if it's possible to pull off, there might be able to be an 057 Battery Preventative Maintenance Crew World Tour at some point that you could sign up for. But, not sure how practical it would really be. Would have to get a lot of signups pretty far in advance to make it possible... although I guess that's not completely out of the realm of possibilities. A hundred+ people onboard would probably make it possible for the US.

But, not sure how practical it would really be. Would have to get a lot of signups pretty far in advance to make it possible... although I guess that's not completely out of the realm of possibilities. A hundred+ people onboard would probably make it possible for the US.

Working with third party shops is tricky, with liability and logistical issues. For example, most shops are just not equipped to do battery work. We've attempted a few remote services for battery replacement work in the past, and it's just too much of a headache. While this maintenance program would certainly be less involved than a full battery replacement, it still involves removing the battery pack from the car and reinstalling it properly.

Another possibility would be to sell a DIY kit + instructions... then can either do it yourself or find a competent shop. I'm not sure I like this idea, though, since it likely would add significant costs all around.

A core issue with this service is that it's just not going to be practical for all of the people who want or need it to get their vehicles to 057 for service, so there's going to definitely need to be a way to do this that's more local to the customers. Combine that with tech throughput (we could probably do 5 of these per day with a dedicated tech pair), and to even address 1% of the potential ~70,000 vehicles in this group, would take years.

So I've put in some work on a plan to be able to do this using... well, let's just say that if it's possible to pull off, there might be able to be an 057 Battery Preventative Maintenance Crew World Tour at some point that you could sign up for.

Working with third party shops is tricky, with liability and logistical issues. For example, most shops are just not equipped to do battery work. We've attempted a few remote services for battery replacement work in the past, and it's just too much of a headache. While this maintenance program would certainly be less involved than a full battery replacement, it still involves removing the battery pack from the car and reinstalling it properly.

Another possibility would be to sell a DIY kit + instructions... then can either do it yourself or find a competent shop. I'm not sure I like this idea, though, since it likely would add significant costs all around.

Did a re-route of the drain today after reading this thread. My pack was replaced in 2020, but the SC did not change out the drain pipe. Here in FL the evaporator sweats alot! Glad to get that water off of the battery... What a design!

another $.02

Kaveman

another $.02

Kaveman

Attachments

Did a re-route of the drain today after reading this thread. My pack was replaced in 2020, but the SC did not change out the drain pipe. Here in FL the evaporator sweats alot! Glad to get that water off of the battery... What a design!

another $.02

Kaveman

It is not clear where exactly the original grain line drains on to. Is the drainage catching the front or the side edge of the pack?

Did a re-route of the drain today after reading this thread. My pack was replaced in 2020, but the SC did not change out the drain pipe. Here in FL the evaporator sweats alot! Glad to get that water off of the battery... What a design!

another $.02

Kaveman

Sorry to be dense; is that the front behind the frunk liner, and you've just run an extension tube some ways away from the top of the battery?

dark cloud

Active Member

Check out this article with great pictures. Article is only a few days old!It is not clear where exactly the original grain line drains on to. Is the drainage catching the front or the side edge of the pack?

Similar threads

- Replies

- 3

- Views

- 328

- Replies

- 24

- Views

- 964

- Replies

- 17

- Views

- 1K

- Replies

- 21

- Views

- 4K

- Replies

- 51

- Views

- 2K