When we installed our outdoor Wall Connector a few years ago, our electrician also recommended (and I concurred) installing a non-fused disconnect next to it, since the breaker panel is indoors. Technically, NEC 625.43 requires a disconnect like this for equipment > 60 amps or > 150V to ground. The wall connector is set for 48 amps, and each leg is only 120V to ground so we should be good without one, but still sounded like a good idea.

Well, he installed one of these and all has been good ... until now.

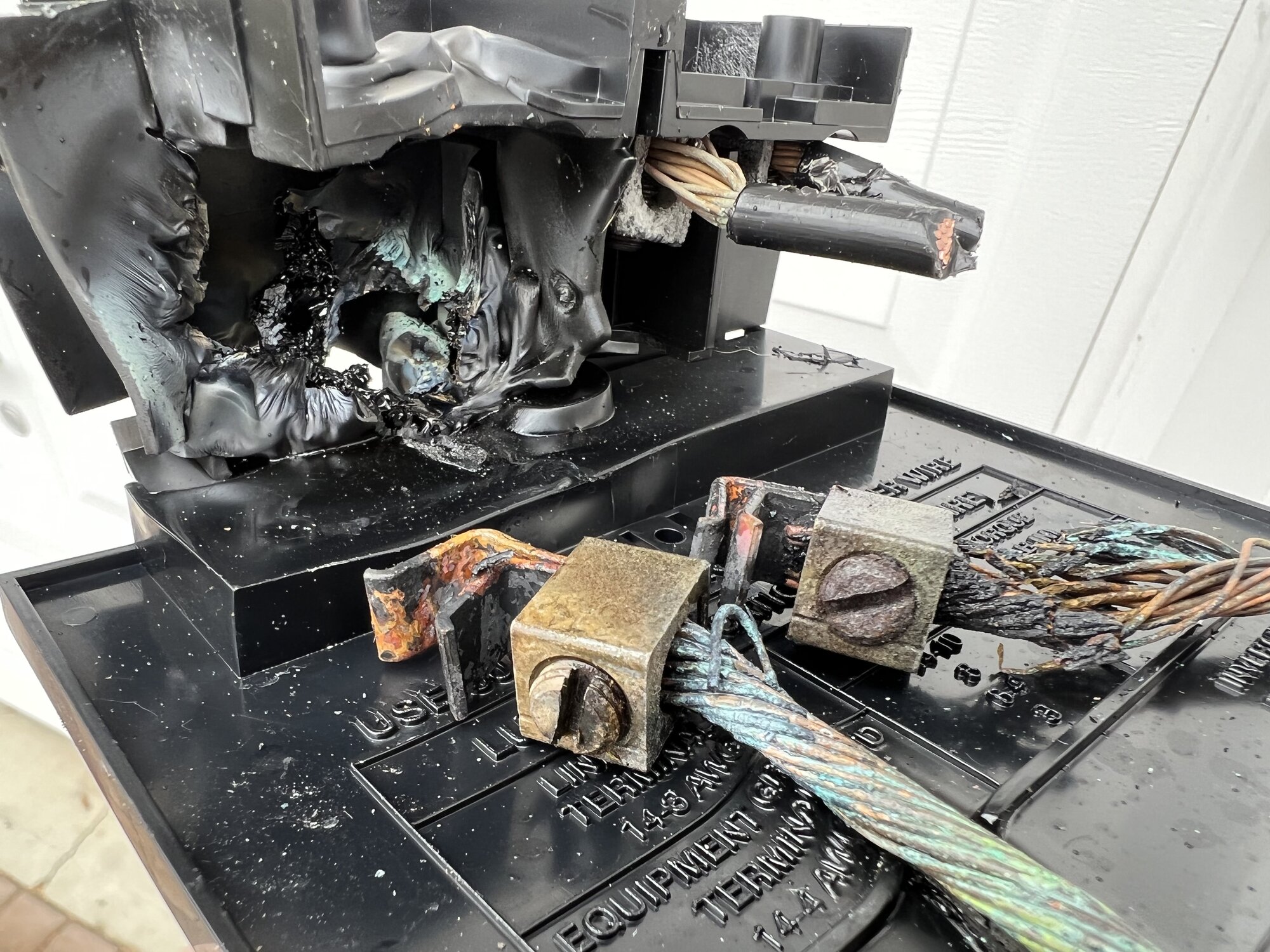

Was outside the other day and got a whiff of burning plastic. My bloodhound-like nostrils led me to the HPWC, and eventually to the disconnect box. Opened it up, only to see this ....

Holy cow! Shut the circuit off immediately (can't exactly pull the non-fused disconnect - it's kinda melted-in-place) and examined what the heck happened here. Looks to me like the fingers that the disconnect slots into are way too thin for a 48A constant draw. You can see one set of fingers was spread open - no spring to them at all - so had a loose connection to the disconnect. Loose connection = resistance = heat = melty disconnect. (Nevermind that surface rust on the contacts - that's because when I cut it out, I threw it on the ground and left it for a few days until the rain stopped.)

Anyway, since NEC doesn't require the disconnect, I decided to cut the wire back to undamaged, and replace the disconnect with a set of Polaris splice blocks. First time using them, but won't be the last. I'm super impressed. Now that it's operational again, once the temperature warms up to the point where I can feel my fingers again, I'm going to clean it up a bit, move that ground block, clean the wires up and apply a little no-ox to it.

Back in business, charging beautifully -- 48A @ 239V. And no plastic-burning smell.

Moral of the story? Keep an eye on these cheap-o disconnects. I'm still pleased with the work the electrician did, but that part is a hunk of junk. I suspect the first time I pulled the disconnect, it bent those fingers on the connector and it's been slowly cooking itself since. Good reminder that we're dealing with a significant power draw here, but these residential manufacturers make MVPs -- Minimum Viable Products. Fast, cheap, reliable - pick two.

Well, he installed one of these and all has been good ... until now.

Was outside the other day and got a whiff of burning plastic. My bloodhound-like nostrils led me to the HPWC, and eventually to the disconnect box. Opened it up, only to see this ....

Holy cow! Shut the circuit off immediately (can't exactly pull the non-fused disconnect - it's kinda melted-in-place) and examined what the heck happened here. Looks to me like the fingers that the disconnect slots into are way too thin for a 48A constant draw. You can see one set of fingers was spread open - no spring to them at all - so had a loose connection to the disconnect. Loose connection = resistance = heat = melty disconnect. (Nevermind that surface rust on the contacts - that's because when I cut it out, I threw it on the ground and left it for a few days until the rain stopped.)

Anyway, since NEC doesn't require the disconnect, I decided to cut the wire back to undamaged, and replace the disconnect with a set of Polaris splice blocks. First time using them, but won't be the last. I'm super impressed. Now that it's operational again, once the temperature warms up to the point where I can feel my fingers again, I'm going to clean it up a bit, move that ground block, clean the wires up and apply a little no-ox to it.

Back in business, charging beautifully -- 48A @ 239V. And no plastic-burning smell.

Moral of the story? Keep an eye on these cheap-o disconnects. I'm still pleased with the work the electrician did, but that part is a hunk of junk. I suspect the first time I pulled the disconnect, it bent those fingers on the connector and it's been slowly cooking itself since. Good reminder that we're dealing with a significant power draw here, but these residential manufacturers make MVPs -- Minimum Viable Products. Fast, cheap, reliable - pick two.