Bunklung

Member

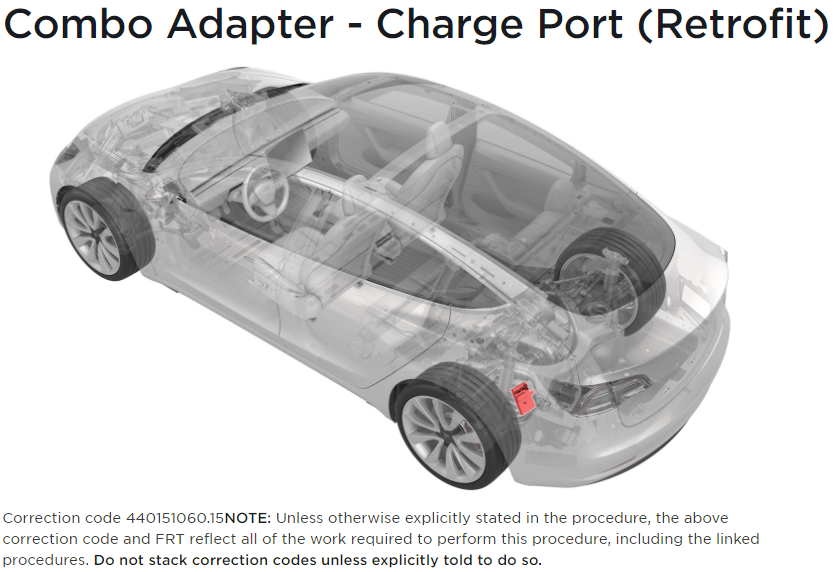

Here is the correction code for the official Tesla retrofit on older model 3:

Correction code 440151060.15 NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

The is found at service.tesla.com and it's under High Voltage -> Charge Inlet -> CCS Retrofit (Thanks to: gjas24 (u/gjas24) - Reddit)

Correction code 440151060.15 NOTE: Unless otherwise explicitly stated in the procedure, the above correction code and FRT reflect all of the work required to perform this procedure, including the linked procedures. Do not stack correction codes unless explicitly told to do so.

The is found at service.tesla.com and it's under High Voltage -> Charge Inlet -> CCS Retrofit (Thanks to: gjas24 (u/gjas24) - Reddit)