ThanksDamn, that is elegant. Nice work.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scrolling wheel on steering wheel easily breaks. Is the part available separately?

- Thread starter Wmcalister

- Start date

ayavner

Member

You should post that write-up on ifixit.com. Anymore, that's my first stop when something around the house breaks... i actually was able to replace the headphone jack in my wife's Samsung galaxy 8+.... as you say, beats whatever they would charge! This is good to see... we really need to get out of the disposable/replaceable mindset.

@David.85D The broken part was 1.72mm across the flats measured with my caliper. I tried a 1/16" (1.59mm) hex wrench (measured at 1.62mm) in the encoder and while it does turn it had a lot of slop in it. I just got lucky that my 1.5mm hex bit was actually 1.7mm and fit perfect. I also tried every 1/16" hex key at harbor freight hoping to find one that fit properly but didn't have any luck. 3D printing might work, but it would take a lot more fussing with it to get it just right, and even then it's not likely to be any stronger than the original. I considered getting some round stock, turning one side down to the right diameter and then grinding a hex onto the other side, but at that point getting it perfectly centered through the wheel would be difficult (it was hard enough to get the hole centered just on the one side). As I did it, the replacement hex shaft is supported inside the wheel by nearly the length it sticks out by, and all the gaps inside are filled with epoxy. If it breaks again the same way I'll be surprised.

Thanks for all that. I guess I’ll have one shortly.@David.85D The broken part was 1.72mm across the flats measured with my caliper. I tried a 1/16" (1.59mm) hex wrench (measured at 1.62mm) in the encoder and while it does turn it had a lot of slop in it. I just got lucky that my 1.5mm hex bit was actually 1.7mm and fit perfect. I also tried every 1/16" hex key at harbor freight hoping to find one that fit properly but didn't have any luck. 3D printing might work, but it would take a lot more fussing with it to get it just right, and even then it's not likely to be any stronger than the original. I considered getting some round stock, turning one side down to the right diameter and then grinding a hex onto the other side, but at that point getting it perfectly centered through the wheel would be difficult (it was hard enough to get the hole centered just on the one side). As I did it, the replacement hex shaft is supported inside the wheel by nearly the length it sticks out by, and all the gaps inside are filled with epoxy. If it breaks again the same way I'll be surprised.

Do you think the original part was round with two flats or really hex shaped?

I suspect they had a "large" 1/16" inch hex. I used a nominally 1.5mm hex that was actually 1.7mm. The hex key that I actually measured at 1/16 was too small for my taste, although it probably would have functioned.On the link in post nr.2 is said 1/16 inch

Rice&Curry

Member

Great improvisation- I guess now this metal part is the strongest part in Tesla.My volume wheel just broke as well, looked the same as what @Pedro.Tx posted a while back. I ended up using the end of the 1.5mm bit (measured 1.7 across the flats) from my mini-screwdriver set (https://amzn.to/3kXOHba). It pained me to take the bit, but for $14 it's a lot cheaper than buying the parts from Tesla.

Steps I took after disassembling the assembly with the wheel in it:

1. Drilled out the broken hex with a 3/32" bit. I went deeper than necessary to give excess epoxy a place to go.

View attachment 706637

2. Cut the end off the bit where it starts to taper down to the 1.5mm end

View attachment 706635

3. Coated the inside of the scroll wheel with epoxy and inserted the bit.

4. After the epoxy started to gel up (I used a 30 minute work life epoxy) I carefully aligned it to make sure it was perpendicular to the face of the wheel.

5. Cured overnight and reassembled.

View attachment 706636

FlatSix911

Porsche 918 Hybrid

A complete kit with a metal shaft and repair Instructions is now available on eBay... no affiliation.I bought a broken one off eBay ;-)

I’ll measure and post more info after I get it. My first choice would be to 3D print a new part that fit a stainless steel pin that ran the whole length and carried all the stress

Scroll Wheel Volume Repair Axle and Repair Instructions for Tesla Model S/X | eBay

Instructions for performing the repair are also included. You can do this yourself for much cheaper, and it will last much longer than the repair provided by Tesla.

www.ebay.com

Sheesh, $45 for a cut down hex key? In case the seller is watching I also needed a T15 or T20 bit to remove the button assembly, I forget which though. And it's not necessary to disconnect the airbag connector, I did the whole thing without disconnecting anything other than the connectors for the controls.A complete kit with a metal shaft and repair Instructions is now available on eBay... no affiliation.

I’ll continue to investigate. My goal is to have an STL for a new scroll wheel that would accept a properly sized metal hex shaft. Then you don’t have to futz around with trying to center and glue the metal piece onto the broken wheel. But that’s just my OCD talking ;-)

@David.85D that seems reasonable, once you have the broken one should be easy enough to model a replacement with a few design iterations. The other thought I had was designing and 3d printing a fixture to allow you to both drill out the old hex accurately and position the new one while the epoxy cures. A 3d printed wheel would be pretty obvious while using the original wheel is totally indistinguishable.

The other thought I had was designing and 3d printing a fixture to allow you to both drill out the old hex accurately and position the new one while the epoxy cures.

this is easy once I have the model of the original wheel.

on a related note, someone mentioned in another thread that new scroll wheels are metal, but the feel isn’t nice compared to the rubbery one.

dark cloud

Active Member

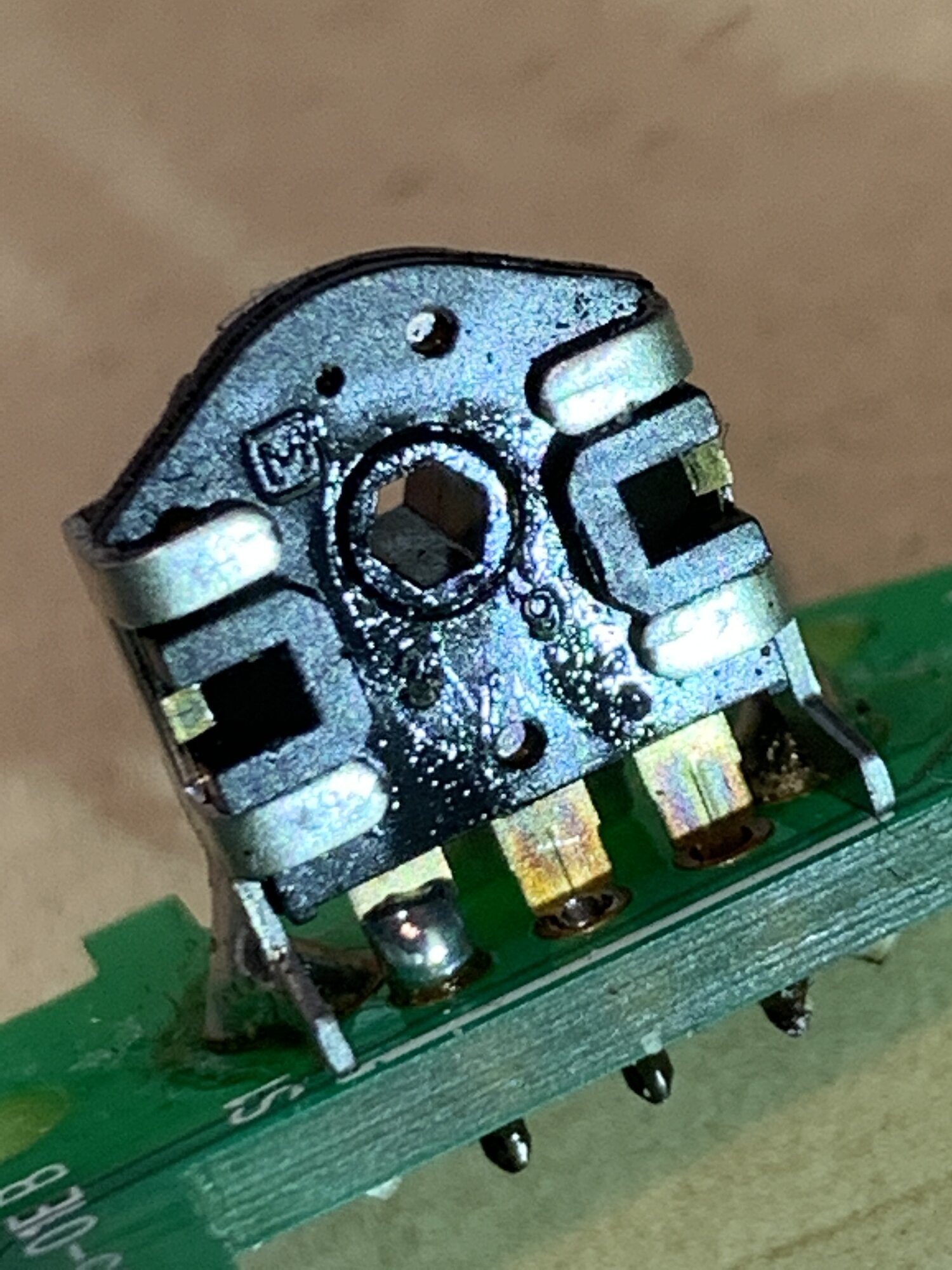

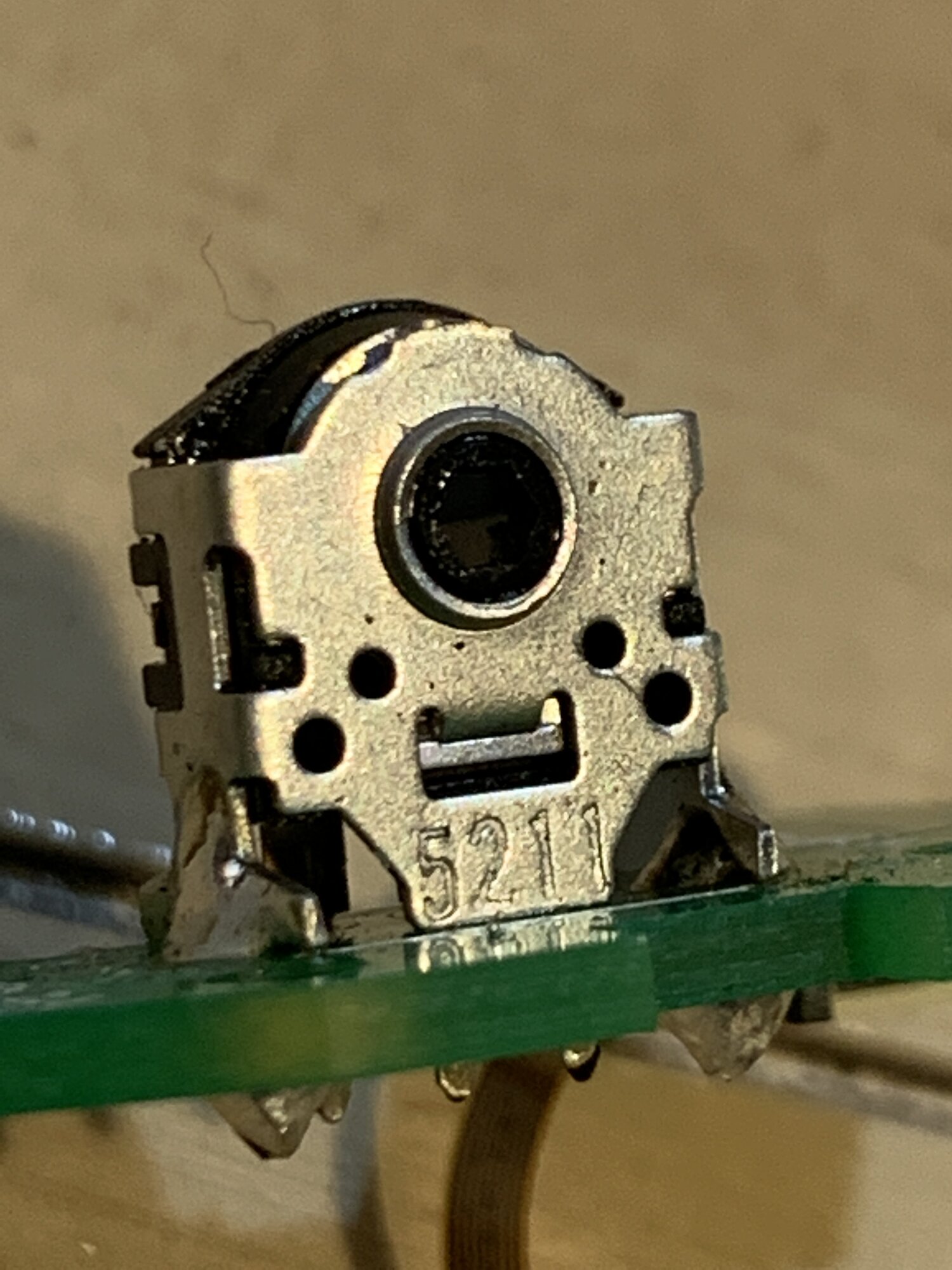

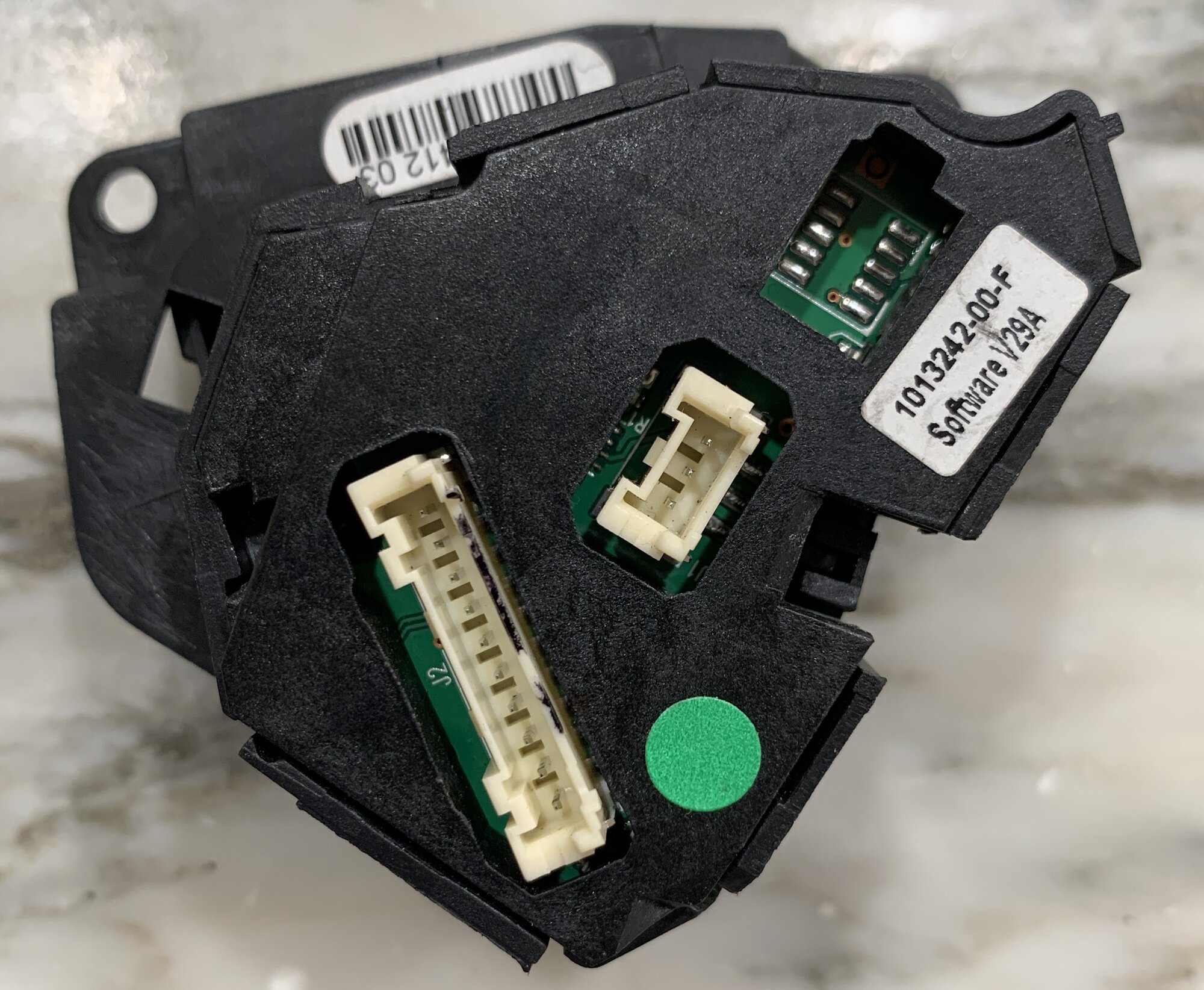

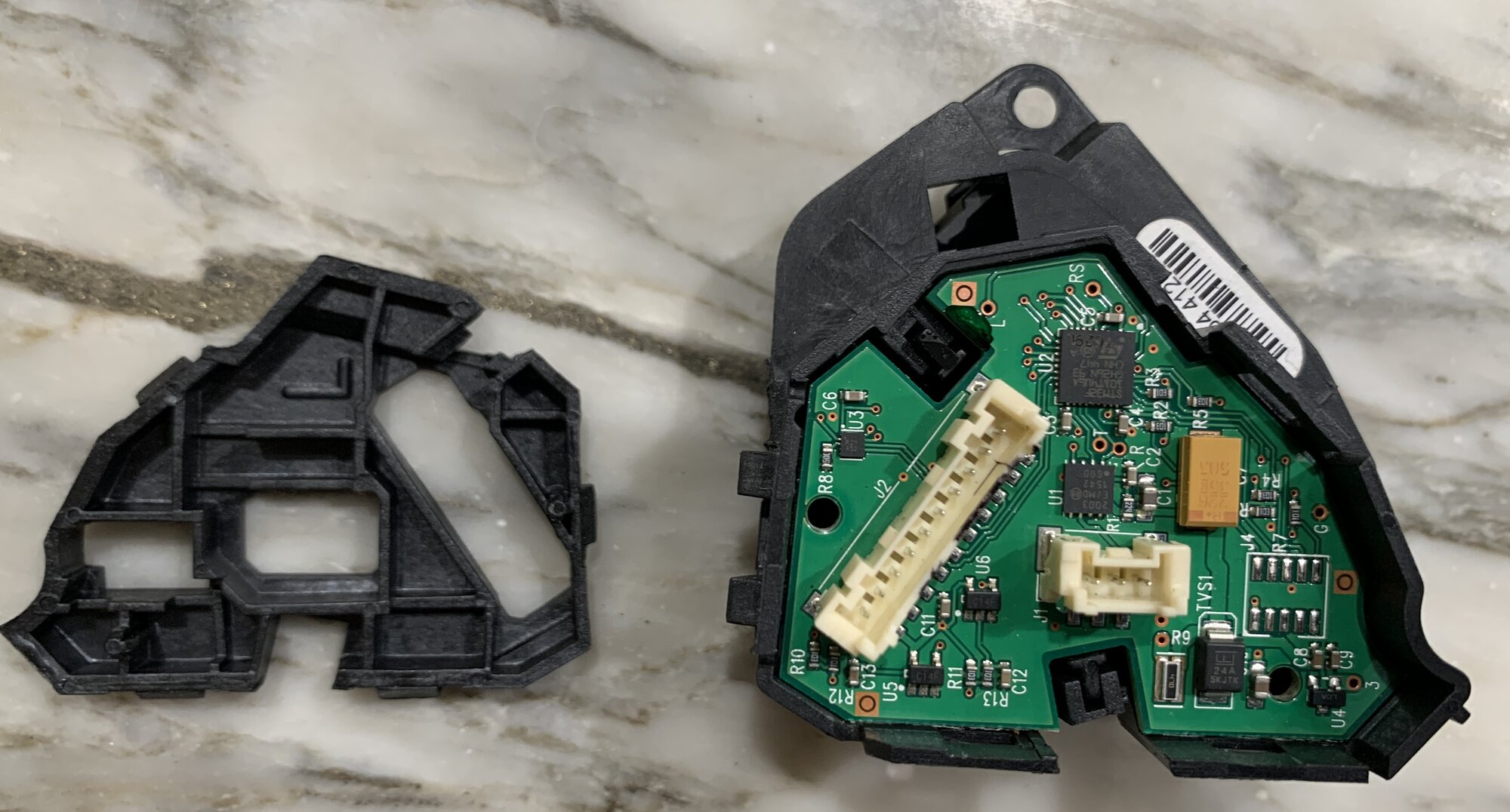

OK. Got my broken unit from ebay. Here are some photos. What I learned is that the encoder is (surprise surprise) a very inexpensive open frame 7mm (tall) mouse wheel rotary encoder. They are standardized with a hex hole that is 1.74mm +- 0.03 mm (a really awful size) which means the shaft can be no bigger than 1.71 mm (0.067 inch) and still fit within tolerance. I was hopeful we would find a 1.7mm hex key, but after searching, I have come up empty handed. I used micrometers to measure the broken shaft and got 0.0672 inches, which makes sense... So that's the target dimension... FWIW, this unit easily came apart with just my pocket knife to lift the snap connectors up. Very easy, tool free design. The soldering is simply atrocious - I am surprised this unit worked at all - maybe the wheels get broken when people start pressing harder when it stops responding?

FlatSix911

Porsche 918 Hybrid

Is the new scroll wheel backward compatible with the old model?this is easy once I have the model of the original wheel.

on a related note, someone mentioned in another thread that new scroll wheels are metal, but the feel isn’t nice compared to the rubbery one.

I would like to retrofit it if it is more durable with a metal shaft.

FlatSix911

Porsche 918 Hybrid

Great design... are you planning to make a few available for sale to TMC members?Will print it in the morning... (This is a render of a solidworks model I just made)View attachment 709077

Similar threads

- Replies

- 15

- Views

- 445

- Replies

- 2

- Views

- 174

- Replies

- 3

- Views

- 254

- Replies

- 143

- Views

- 7K