Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Semiconductor Shortage and Car Production

- Thread starter gnuarm

- Start date

Terminator857

Active Member

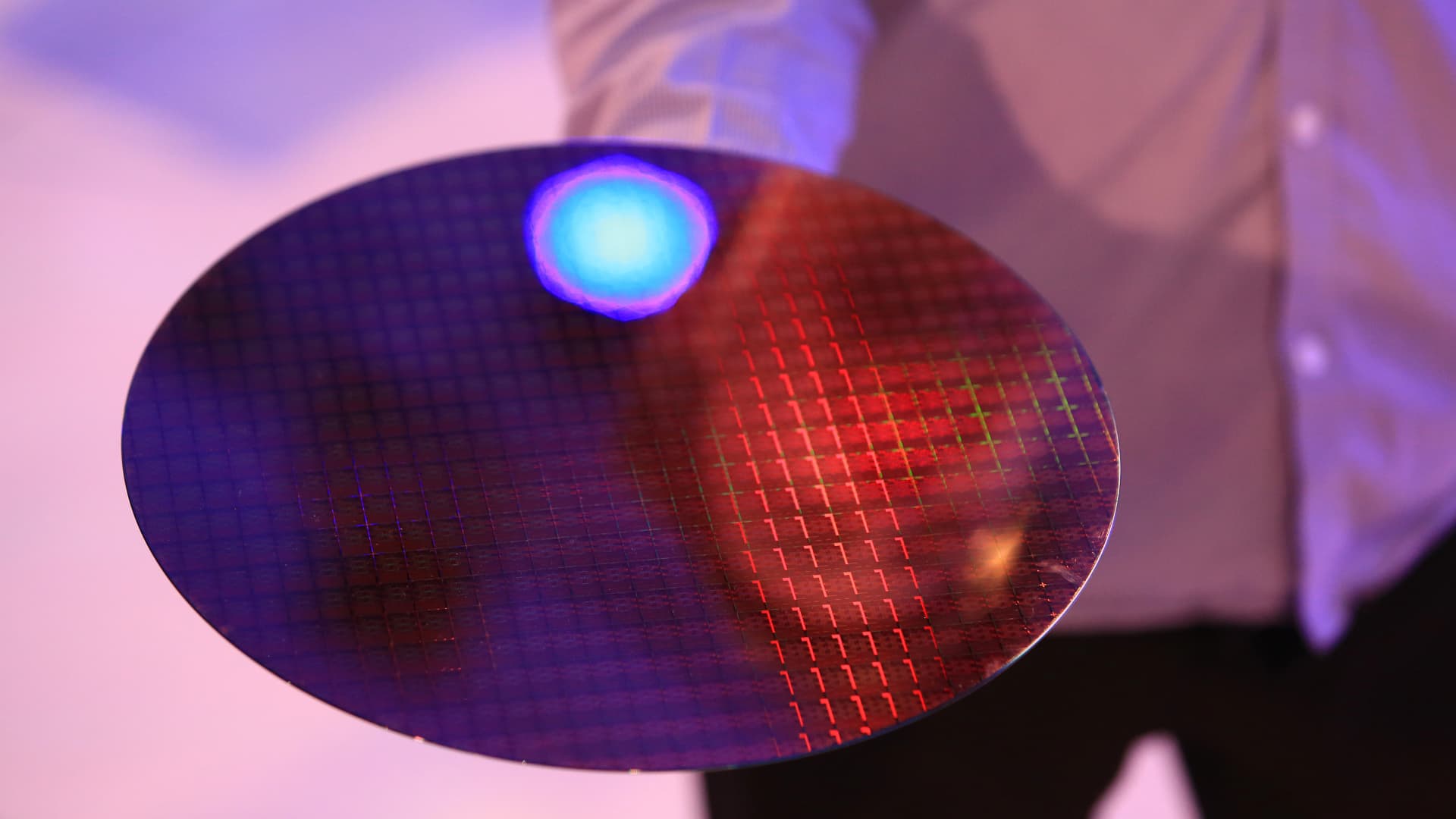

A Tiny Part’s Big Ripple: Global Chip Shortage Hobbles the Auto Industry (Published 2021)

Almost every carmaker has had to curtail production, hampering the economic recovery.

Porsche warned dealers in the United States this month that customers might have to wait an extra 12 weeks to get their cars, because they lack a chip used to monitor tire pressure.

One big reason automakers can’t find enough chips is that semiconductor manufacturers have given priority to manufacturers of smartphones, video game consoles and other consumer electronics, which tend to be more lucrative customers.

A modern car can easily have more than 3,000 chips.

Over all, the chip shortage and other supply chain snarls curtailed production by 1.3 million vehicles in the first three months of the year, according to IHS Markit, a consultancy.

General Motors, which has had to halt production temporarily at a half-dozen plants since the beginning of the year, has in some cases been producing cars without electrical components and parking them until the parts are available. Ford Motor said Wednesday that it would keep several U.S. plants idle longer than expected because of the chip shortage.

“We are missing the most simple of chips, that maybe only cost cents or dollars,” he said. “That’s holding us up from building a product that costs $75,000.”

Terminator857

Active Member

Quote:

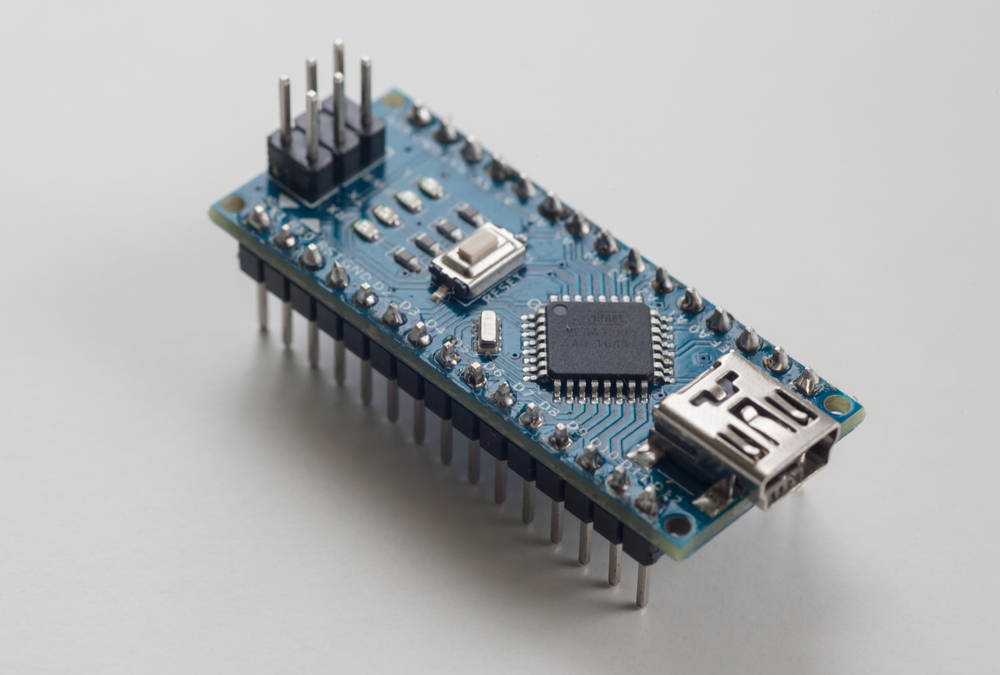

Meanwhile, fab capacity for power and compound semiconductors is seen leveling off beginning at the end of this year, with the rate of increase declining steadily through 2024 as fab capacity begins to meet pent-up demand for automotive electronics.

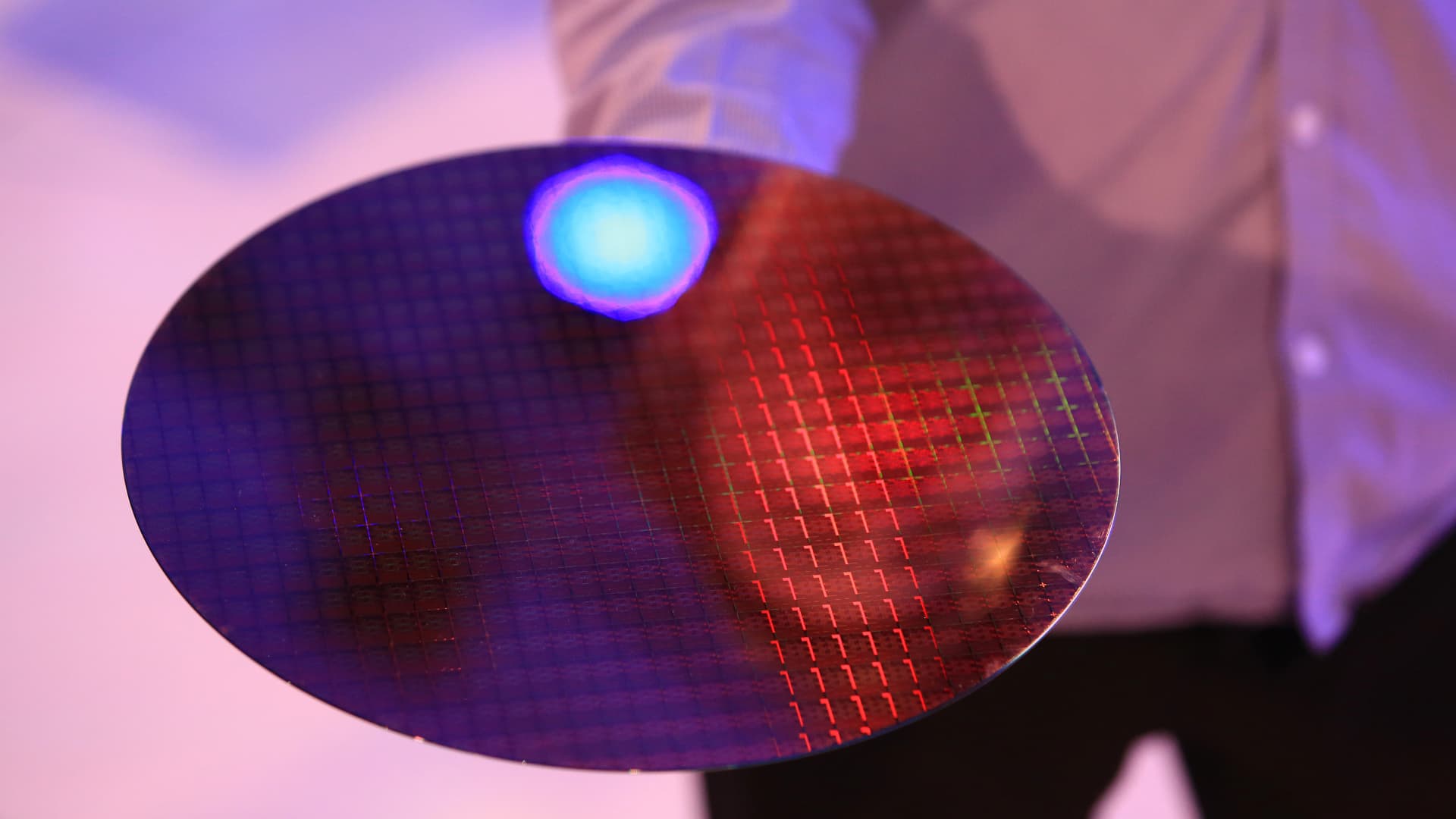

Installed capacity for power and compound semiconductor fabs is projected to reach 10.6 million wafers per month (in 200-mm equivalents) by 2024. China is leading the ramp aimed at meeting surging automotive demand, accounting for about one-third of installed wafer capacity by 2023.

Meanwhile, fab capacity for power and compound semiconductors is seen leveling off beginning at the end of this year, with the rate of increase declining steadily through 2024 as fab capacity begins to meet pent-up demand for automotive electronics.

Installed capacity for power and compound semiconductor fabs is projected to reach 10.6 million wafers per month (in 200-mm equivalents) by 2024. China is leading the ramp aimed at meeting surging automotive demand, accounting for about one-third of installed wafer capacity by 2023.

Terminator857

Active Member

Toyota cuts February output, expects to miss annual production target on chips crunch

Toyota had been aiming for a high February production plan to meet strong demand.

After holding strong for months, Toyota now expects to miss its global production target as the automaker capitulates to the double whammy of parts shortages and the pandemic.

Toyota said it expects global production to come in under the 9 million-vehicle target for its fiscal year to March 31 that the company had been clinging to since last autumn. It's the second time this fiscal year that Toyota has dialed down its companywide production figure.

In a statement on Tuesday, Toyota said the semiconductor shortage would force it to reduce worldwide output by 150,000 units in February to about 700,000 vehicles. Toyota put the blame for the February downturn on the ongoing microchip crisis.

Terminator857

Active Member

Used car prices start to decline

www.cargurus.com

www.cargurus.com

Used Car Price Trends - CarGurus Pricing Index

Stay on top of used car price trends and get real-time industry-leading market insights.

Terminator857

Active Member

GM declares chip crisis over—and says it's time to let the cheap cars roll

The carmaker's confidence this early in the year surprised analysts skeptical it can boost global annual production volumes by 25% at least.

General Motors expects to boost global volumes by 25% to 30% this year as it bulks up production of smaller, more affordable crossovers and sedans that could not be built previously due to missing chips.

..., executives from the Detroit manufacturer say the crisis appears to be over. Supply remains constrained, yet it continues to steadily improve since the third quarter.

“The run rate that we’ve seen sequentially from 3Q to 4Q to 1Q is giving a heightened level of confidence,” finance chief Paul Jacobson told investors during an earnings call on Tuesday. “We expect ongoing semiconductor availability improvements throughout 2022.”

Terminator857

Active Member

China is being hit hard by U.S. sanctions on advance chip making equipment.

DanCar

Active Member

/cloudfront-us-east-2.images.arcpublishing.com/reuters/W3NOV7GNFZNPHMW2M4HDKZFGIM.jpg)

Automakers, chip firms differ on when semiconductor shortage will abate

Automakers, including General Motors , Ford Motor and Hyundai Motor , predict a near two-year chip constraint will ease in the second half of 2022, but automotive chipmakers, on the other hand, expect a recovery to take longer.

Automakers, including General Motors (GM.N), Ford Motor (F.N) and Hyundai Motor (005380.KS), predict a near two-year chip constraint will ease in the second half of 2022, but automotive chipmakers, on the other hand, expect a recovery to take longer.

During their quarterly results reporting over the past two weeks, GM CEO Mary Barra projected the semiconductor shortage would diminish in the second half, Ford forecast a significant improvement in the second half after a first-quarter low in vehicle sales, and Hyundai predicted chip supply would return to normal levels in the third quarter of this year.

Tesla (TSLA.O), which managed chip supplies last year through strategies including writing new software to handle changes in chips, expects chip shortages to last through this year before easing next year.

Chief Executive Elon Musk told an earnings call last month the shortage was not a long-term issue, with factories increasing capacity and automakers guilty of panic buying of chips which slowed the supply chain.

He described that to investors in blunt terms. "I think there's some degree of the toilet paper problem as well, where, you know, there was a toilet paper shortage during COVID, and like, obviously, it wasn't really certainly a tremendous enhanced need for ass wiping. It's just people panicked..."

DanCar

Active Member

Made up example of the toilet paper problem mentioned above by Elon:

Toyota has a 4 month supply of radar chips. GM needs radar chips but has 4 month supply of pic controllers that cost 50 cents each. Toyota has trouble shipping because it needs pic controllers.

Toyota has a 4 month supply of radar chips. GM needs radar chips but has 4 month supply of pic controllers that cost 50 cents each. Toyota has trouble shipping because it needs pic controllers.

Terminator857

Active Member

Ford says it has a problem with 37 suppliers: Ford pushing back dealer allocations until late May; 100,000 units lost as suppliers struggle to deliver parts

Terminator857

Active Member

Ford shipping vehicles without rear climate control because of chip shortage.

jalopnik.com

List of features lost because of parts shortages:

jalopnik.com

List of features lost because of parts shortages:

www.carexpert.com.au

Some excerpts:

www.carexpert.com.au

Some excerpts:

Audi - Wireless phone charger

BMW - Adaptive cruise control

Mercedes

www.express.co.uk

www.express.co.uk

Renesas which has been blamed for parts shortage in the past, shuts down production due to earthquake:

/cloudfront-us-east-2.images.arcpublishing.com/reuters/LBVKMPKWGJNH5B7W6UM72QIWYY.jpg)

www.reuters.com

www.reuters.com

europe.autonews.com

europe.autonews.com

Ford Plans To Ship Cars That Are Missing Features To Dealers Because Of The Chip Shortage

The company said that the missing features will be installed in the vehicles within a year.

jalopnik.com

jalopnik.com

Running list of cars with spec changes, due to chip shortage

Here are some of the cars confirmed to have had features temporarily removed due to the global semiconductor shortage.

Audi - Wireless phone charger

BMW - Adaptive cruise control

Mercedes

- Autonomous emergency braking

- Adaptive cruise control

- Blind-spot assist

- Rear-cross traffic alert

- Exit warning

Putin sparks EU panic as shortage of key materials force car plants

RUSSIA'S invasion of Ukraine is sparking panic across Europe as the shortage of key materials is threatening to shut down car plants.

Renesas which has been blamed for parts shortage in the past, shuts down production due to earthquake:

/cloudfront-us-east-2.images.arcpublishing.com/reuters/LBVKMPKWGJNH5B7W6UM72QIWYY.jpg)

Japan parts makers halt output after quake, another blow to supply chain

Japan's Renesas Electronics Corp, Murata Manufacturing Co Ltd, Sony Group Corp and other precision parts makers halted some operations on Thursday after an earthquake jolted the country's northeast, the latest blow to the global supply chain.

Renesas suspends semiconductor plants in Japan after earthquake

Three Renesas chip plants in Japan were affected after a major earthquake hit the country’s northeast.

Last edited:

Terminator857

Active Member

List of features missing from Buick models. Similar for other GM cars.

gmauthority.com

gmauthority.com

2022 Buick Models Get New Microchip Shortage Constraints

Several features are currently affected.

gmauthority.com

gmauthority.com

| Heated Steering Wheel | Heated Front Seats | Ventilated Front Seats | Heated Outboard Rear Seats | Power-Folding 3rd Row Seat | Rear Park Assist | Front And Rear Park Assist |

|---|

Terminator857

Active Member

If you are some micro controllers now, you will get them in a year:

www.theregister.com

www.theregister.com

Chip shortage: Engineers complain of prices, lead times

Never mind those flashy GPUs, MCU drought hits health to automotive

Terminator857

Active Member

VW doesn't expect the chip supply problem to be solved this year.

/cloudfront-us-east-2.images.arcpublishing.com/reuters/7NHMAMT27VKD5KIC5DCEFQ7TQM.jpg)

www.reuters.com

www.reuters.com

/cloudfront-us-east-2.images.arcpublishing.com/reuters/7NHMAMT27VKD5KIC5DCEFQ7TQM.jpg)

Chip undersupply to last until 2024, says Volkswagen CFO

Semiconductor chip supply is unlikely to be enough to completely satisfy demand again until 2024, Volkswagen Chief Financial Officer (CFO) Arno Antlitz said in an interview with German daily Boersen-Zeitung on Saturday.

Terminator857

Active Member

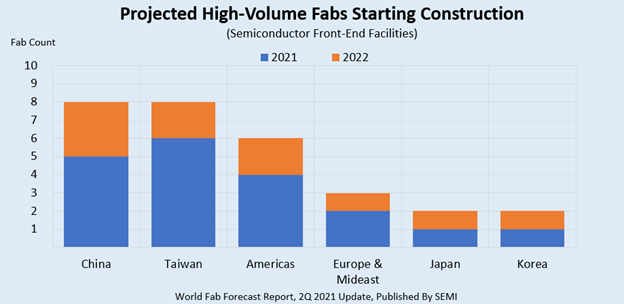

Article from 10 months ago: 29 new semiconductor fabrication plants coming. Will cause $140 billion dollars in spending for manufacturing equipment.

From more than a year ago: Intel to spend $20 billion for two new fabs in Chandler Arizona.

www.allaboutcircuits.com

www.allaboutcircuits.com

www.cnbc.com

www.cnbc.com

Outer shell of TSMC's Arizona fab complete this year and equipment setup to start next year:

asia.nikkei.com

asia.nikkei.com

www.tomshardware.com

TSMC says it will spend $35 billion over the next 8 years on the Arizona fab:

www.tomshardware.com

TSMC says it will spend $35 billion over the next 8 years on the Arizona fab:

It takes more than 2 years from start of building a semiconductor plant to start of manufacturing and about 3 years to reach high volume manufacturing.

Samsung plant in Austin to go online by end of 2023, cost $17 billion. Samsung Foundry: New $17 Billion Fab in the USA by Late 2023

China spending $150 billion on semiconductor manufacturing capabilities:

From more than a year ago: Intel to spend $20 billion for two new fabs in Chandler Arizona.

New Fabs Crop Up Globally in 2021 as Chip Crisis Continues - News

GlobalFoundries, SK Hynix, and Intel have all announced plans to either break ground on new manufacturing plants or expand existing operations.

Intel is spending $20 billion to build two new chip plants in Arizona

Intel also said on Tuesday that it will act as a "foundry," or a manufacturing partner, for other chip companies.

Outer shell of TSMC's Arizona fab complete this year and equipment setup to start next year:

Construction of TSMC's U.S. chip plant delayed by labor crunch, COVID

Taiwan chip titan faces fight for workers as Intel also builds in Arizona

TSMC Will Reportedly Move Equipment Into Arizona's Fab21 in Q1 2023

Mass production plans remain on track for early 2024.

It takes more than 2 years from start of building a semiconductor plant to start of manufacturing and about 3 years to reach high volume manufacturing.

Samsung plant in Austin to go online by end of 2023, cost $17 billion. Samsung Foundry: New $17 Billion Fab in the USA by Late 2023

China spending $150 billion on semiconductor manufacturing capabilities:

Last edited:

Terminator857

Active Member

Somewhat off topic: Department of Defense spending money on domestic chip production.

DoD Announces $117 Million Defense Production Act Title III Agreement With GlobalFoundries

As part of the nation's effort to sustain the microelectronics manufacturing capability necessary for national and economic security, and in support of Executive Order 14017, America’s Supply Chains,

www.defense.gov

Terminator857

Active Member

Video touches on different subjects, but mostly about Samsung new FAB in Texas to start production by 2024.

Terminator857

Active Member

Car inventories have increased for 3 consecutive months.

wardsintelligence.informa.com

wardsintelligence.informa.com

U.S. Light-Vehicle Inventory in July Records First Year-Over-Year Increase Since 2019

<p style="margin-top: 6pt;"><span>Although inventory declined from the prior month in July, U.S. light-vehicle sales in August are expected to improve on July’s 13.4 million-unit seasonally adjusted annual rate and post a third consecutive month-to-month increase.</span></p> <br class="t-last-br" />

UkNorthampton

TSLA - 12+ startups in 1

Light truck inventories?Car inventories have increased for 3 consecutive months.

U.S. Light-Vehicle Inventory in July Records First Year-Over-Year Increase Since 2019

<p style="margin-top: 6pt;"><span>Although inventory declined from the prior month in July, U.S. light-vehicle sales in August are expected to improve on July’s 13.4 million-unit seasonally adjusted annual rate and post a third consecutive month-to-month increase.</span></p> <br class="t-last-br" />wardsintelligence.informa.com

Cars still looks like trending down (with blips).

Something to do with cost of fuel and lack of supply for Electric Vehicles (mostly cars)?

Light trucks make the most profit, so manufacturers should prioritise them, but then might find the market goes into a "Valley Of Death" hidden by chip shortages and covid

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 9

- Views

- 1K

- Replies

- 11

- Views

- 637