Hi, I have a Model S 2014 P85+

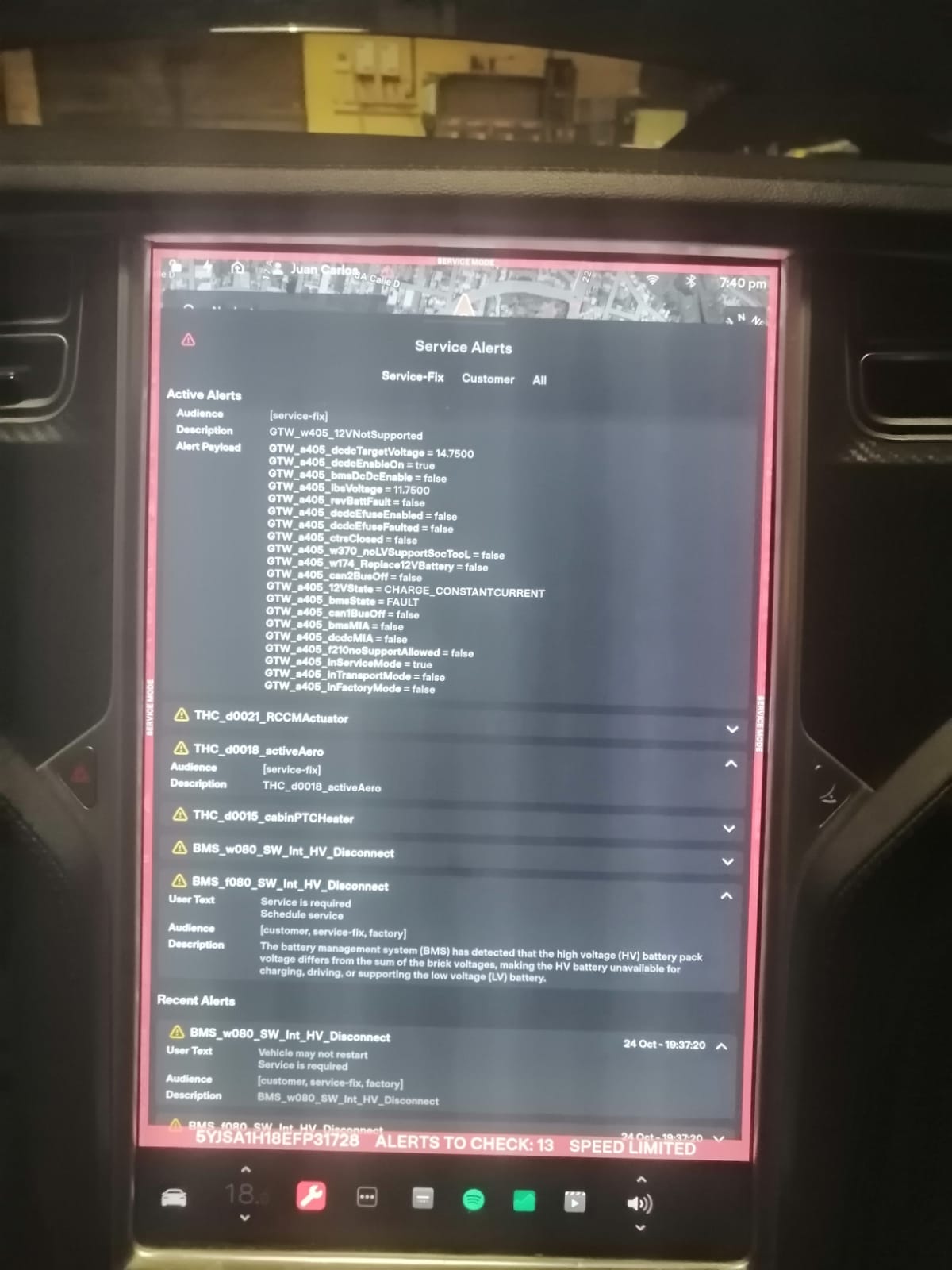

Last Monday I was driving it near from my house in Guatemala, but the car suddenly stoped with the warning: “Unable to drive, supply voltage too low”… I thought that would be a 12V battery failure, so, on my own, I replaced it for a new one. Yesterday, after installed it, the car woke up with 13 alerts on it, so I put it on “Service Mode” and take some pictures of the screen (please find them attached to this email),

The more stressful alert for me was: BMS_f080_SW_Int_HV_Disconnect: the BMS has detected that the HV battery pack voltage differs from the sum of the brick voltages, making the HV battery unavailable for charging, driving or supporting the LV battery…

It look like is something is either not connected completely or properly from the battery, or maybe a problem with the HV battery itself?

Can somebody help me, where should I start to solve this problem?

Thanks a lot for your valuable help!

Juan Carlos

Last Monday I was driving it near from my house in Guatemala, but the car suddenly stoped with the warning: “Unable to drive, supply voltage too low”… I thought that would be a 12V battery failure, so, on my own, I replaced it for a new one. Yesterday, after installed it, the car woke up with 13 alerts on it, so I put it on “Service Mode” and take some pictures of the screen (please find them attached to this email),

The more stressful alert for me was: BMS_f080_SW_Int_HV_Disconnect: the BMS has detected that the HV battery pack voltage differs from the sum of the brick voltages, making the HV battery unavailable for charging, driving or supporting the LV battery…

It look like is something is either not connected completely or properly from the battery, or maybe a problem with the HV battery itself?

Can somebody help me, where should I start to solve this problem?

Thanks a lot for your valuable help!

Juan Carlos