All on one cabinet? 4 stalls immediately adjacent? All at the same time? Really? That is extremely likely? Hmm, I guess I have been extremely unlucky to have never ever seen this if it is so common.

If the bus is shared as you suggest means every single component in the cabinet on the incoming side has to be capable of 1mw of power. That’s 1200A at 480V. Derate 80% for charging and you need 1500A input capability per cabinet (and what are they doing with a 1600A breaker for 12 stalls? Shouldn’t it be 4500A?).

Which size cable is that?

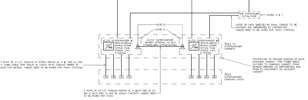

View attachment 848669

2000 kcmil cable is 1.4-1.6 INCHES in diameter. 3 phase power requires 4 wires. 6 inch conduit can only hold 3 2000 kcmil cables. Maybe the ground is small enough to also pass through.

500 kcmil is $30/ft, 1000 kcmil is $90/ft, couldn’t find pricing on 2000 kcmil but at least $180/ft, maybe as much as $270/ft x 3 wires so $800/ft x # cabinets. At $100k valuation for 8 stalls, that’s 125 ft of wire max and that leaves no money to pay workers or for anything else needed on the electrical side. WAIT! 2000 kcmil is only 750A so you’d need 2 runs for every cabinet. $1600/ft and only 62ft max cable per 8 stall site.

All of the full power sharing sounds great until you factor reality. Just like 4680. Just because someone said the DC bus is shared doesn’t mean it works that each cabinet can output 250kw x 4 stalls. Just because Tesla says it’s a 1mw cabinet, doesn’t mean it actually outputs that. The cabinet is limited by code and design based on internal wiring as to how much it can accept and output. And the on site transformer. As stated above, that is 430A or 360kw (which lines up nicely with the 430 max ampacity at 90C for 500 kcmil cable). This is more than the combined output of 300kw of 2 V2 cabinets but not much more. The sharing is better, you aren’t immediately cut to 75kw when someone plugs in next to you but it is still not capable of delivering 4x 250kw from the same cabinet.

If you would like to prove this wrong, please document (with video) 4 cars plugging in to 4 stalls from the same cabinet on an entirely empty V3 site (it’ll allow for full power sharing as you suggest) and getting over 360kw combined output at any time. You need 1290A of 480V 3 phase power to output 1mw. So your chosen V3 site better be at least 12 stalls or there won’t be enough power.

From Wikipedia:

“A 1 MW charge box supplies 4 stalls at up to 250 kW each,

[38][39] and can have a 575 kW battery storage. However the grid input is limited to around 350 kW.”

350kw in and 1000kw out? Now THAT would be amazing synergy right there.

@pdx_m3s I wasn’t implying it was. Just pointing out what people like pb thinks is likely isn’t possible whether it happens or not and if it was so likely, why wouldn’t Tesla have designed the system to handle that? Right, because it doesn’t happen. 360kw across 4 stalls is plenty since 4 cars never arrive to the same cabinet at once.