To prevent water incursion, I am thinking about finding the lowest part of the pull cable, either cut a small slot or drill a small hole so that any water drips down through the latch area will drip away before it pools up in the sheath and work its way into the motor. Obviously, all the seams of the motor should be sealed with silicone too. It's too bad that we have to do things to mitigate the bad or cheap design. Worse, deal with a failure. I, for one, would gladly pay a bit more and have a better product. Are you listening--Hansshow and EVOffer?

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What to do when Power Frunk Completely Fails to Open?

- Thread starter JustAnotherY

- Start date

I think the part EVOffer/Hansshow use is meant to be installed in or to something else. It clearly isn’t designed FOR Teslas, it just works with the kit they provide.

If I were installing my auto frunk again I’d seal all of the joints with silicone, including the screw heads, and also aim to stick it inside a bag or box of some kind.

If I were installing my auto frunk again I’d seal all of the joints with silicone, including the screw heads, and also aim to stick it inside a bag or box of some kind.

bobbythecat

New Member

what i did was remove the power frunk ECU, suction motor and lock bracket. put everything to stock but leave the power struts. Now you can open and close the frunk but you would have to Manuel push down the frunk to lock it. other then that it works. you can use your screen , and your phone to open and closing it to the latch, but you will have to push down to lock it all the

I thought the power struts needs the ECU to operate? In this case what is "sending the signal" to the power struts to get them to close/open ?

I thought the power struts needs the ECU to operate? In this case what is "sending the signal" to the power struts to get them to close/open ?

The power struts plug into the harness that plugs into the frunk control box so I have absolutely no idea how that’s supposed to work?

Since the struts have no power it's working like a manual frunk. You still have to lift it and close it by hand.

KevinT3141

Member

This seems to be the most recent thread on this issue, so I'm adding our experience. (There's a TLDR at the bottom for those that want to skip the novel.)

My wife's a visiting nurse, going in to multiple houses and schools all day, and the frunk seemed a great place to store her nursing supplies and equipment as it's dry, secure, and easily accessible when backing into parking spots. Getting her hands dirty all the time opening and closing it was a non-starter though, so I installed the Hansshow power frunk to make her life easier. Five months to the day after installing it though, it jammed closed. I thought it would just be a quick pull of the manual release to get back in to fix (or disconnect) it, but as many have discovered, that's often not the case.

For a while we ignored the issue as I had a major snowboard trip to go on and winter isn't the greatest time for DIY, but shortly after I got back the washer fluid ran low. (Thank you relentlessly-stupid-but-largely-ineffectual-on-greasy-winter-roads, auto-engaged, auto wipers!) We couldn't ignore the problem any longer, so last weekend we heated the garage as best we could and I took the plunge.

I started by jacking the front of the car (yes, with the proper pucks) to set the wheels on ramps and get underneath. My plan was to access the latch by removing the lower portion of the front bumper, called the valance in Tesla's service manual. The manual has you pull the entire fascia just to get the valence off; a non-starter when you can't open the frunk to undo the bolts at the top, and it also showed internal clips joining the valence to the fascia. Ugh. So I gave up on that and worked on the fender liners, borrowing some jack stands to support the suspension while pulling the wheels. Things were getting ugly, but I didn't want to pay the big $$$ to Tesla to take the car apart and risk any opportunity to get the power frunk working again. Once the liner was out of the driver's side fender, I got a good view of how the valance attached to the fascia, popping the internal clips for better access.

Unfortunately, as many have discovered (but I hadn't yet realized), you can't access the latch from under the valance because of the giant horizontal radiator in the way. What I could get to though was the power frunk retractor cable, and the giant zip ties holding its motor in place:

I know some folks here have just cut the retractor cable at this point, but I figured I could snip the zip ties to release the motor, hopefully getting enough access to unplug it and poke some voltage down its connector. With the zip ties cut and the motor unplugged, it dropped down to where I could handle it, and I discovered that its release cable was kinked:

Unthreading that cable from the bumper so it was entirely external to the car along with the motor, I held it in a nice straight line to try one more pull, and huzzah!, it moved and released something. I grabbed my phone, popped the frunk in the app, and to my intense relief it opened automatically just as if nothing was wrong. I reconnected the motor, hit the button in the frunk to close it, and it happily auto-closed but would not latch.

After a few more cycles without success, I finally figured out how to reset the manual release: Once the power struts have the hood just about closed, push it down to manually to latch it. The retractor motor spins until it hits resistance, reverses as normal, and is magically reset. After that I played with both the power functions and manual release a few more times, just to verify the proper operation and reset.

In hindsight, I think I recall a kink in the release cable at the motor when I first installed it, but I never tested it (big mistake!) because Hansshow's instructions tell you not to pull it; implying that it's some sort of one-time use thing. It's not.

So now it was time to pull the frunk tub and put everything back together. Without more of the giant zip ties that came with the kit, I combined what was to hand and took extra steps to ensure that the manual release cable was not kinked:

When I first installed the kit I didn't use the double-sided tape pads Hansshow provided, as the motor is such an irregular shape that I didn't think it would do any good. This time there's a big piece under the motor so it can't slide down that diagonal bar to kink the emergency pull against the shotgun. (The gap there's bigger than it looks in the photo above). I didn't think to do it at the time, but when I have it apart again in spring to replace those red zip ties with beefier ones, I'll also lube the release cable with high viscosity oil. I've used it in the past to unjam grip-shifter cables on kids bikes, and it really gets in there from end to end. It should help prevent internal corrosion, and hopefully make the cable even easier to pull. (It's already pretty good now that the kink's out of it.)

Before buttoning everything back up I tested it a few more times, including pulling the release in its final position behind the emergency access hole in the bumper. With everything good, I got it back together, then took it through the car wash for the wife because of all my hand prints in what TeslaBjörn calls the winter salts-schmutz-fest. (Who expects a 15-minute line up at the car wash after midnight?!) She doesn't fully trust it yet (and I can't say that I blame her), so hasn't put anything back into it. We do cycle it every few days though to make sure that it still works, and hopefully our trust will return over time. It was certainly a brilliant and highly useful feature for those first couple of months.

Looking back, I wasted a lot of time under the car (and unfastened a lot of garnishes, clips, and bolts) that I didn't need to. If this happens again, I'm pretty sure that I can snip the zip ties and access the retractor motor from just the driver's side fender without even pulling the entire liner, and I made sure to leave enough slack in the wiring for that with the motor in its new position. Hopefully things won't come to that again, but we'll see.

TLDR: I still don't know why the retractor jammed, but the emergency release works if you're careful to install it without any kinks, and we got our power frunk back. I'd also suggest lubing the emergency release cable with a high viscosity oil to prevent internal corrosion.

My wife's a visiting nurse, going in to multiple houses and schools all day, and the frunk seemed a great place to store her nursing supplies and equipment as it's dry, secure, and easily accessible when backing into parking spots. Getting her hands dirty all the time opening and closing it was a non-starter though, so I installed the Hansshow power frunk to make her life easier. Five months to the day after installing it though, it jammed closed. I thought it would just be a quick pull of the manual release to get back in to fix (or disconnect) it, but as many have discovered, that's often not the case.

For a while we ignored the issue as I had a major snowboard trip to go on and winter isn't the greatest time for DIY, but shortly after I got back the washer fluid ran low. (Thank you relentlessly-stupid-but-largely-ineffectual-on-greasy-winter-roads, auto-engaged, auto wipers!) We couldn't ignore the problem any longer, so last weekend we heated the garage as best we could and I took the plunge.

I started by jacking the front of the car (yes, with the proper pucks) to set the wheels on ramps and get underneath. My plan was to access the latch by removing the lower portion of the front bumper, called the valance in Tesla's service manual. The manual has you pull the entire fascia just to get the valence off; a non-starter when you can't open the frunk to undo the bolts at the top, and it also showed internal clips joining the valence to the fascia. Ugh. So I gave up on that and worked on the fender liners, borrowing some jack stands to support the suspension while pulling the wheels. Things were getting ugly, but I didn't want to pay the big $$$ to Tesla to take the car apart and risk any opportunity to get the power frunk working again. Once the liner was out of the driver's side fender, I got a good view of how the valance attached to the fascia, popping the internal clips for better access.

Unfortunately, as many have discovered (but I hadn't yet realized), you can't access the latch from under the valance because of the giant horizontal radiator in the way. What I could get to though was the power frunk retractor cable, and the giant zip ties holding its motor in place:

I know some folks here have just cut the retractor cable at this point, but I figured I could snip the zip ties to release the motor, hopefully getting enough access to unplug it and poke some voltage down its connector. With the zip ties cut and the motor unplugged, it dropped down to where I could handle it, and I discovered that its release cable was kinked:

Unthreading that cable from the bumper so it was entirely external to the car along with the motor, I held it in a nice straight line to try one more pull, and huzzah!, it moved and released something. I grabbed my phone, popped the frunk in the app, and to my intense relief it opened automatically just as if nothing was wrong. I reconnected the motor, hit the button in the frunk to close it, and it happily auto-closed but would not latch.

After a few more cycles without success, I finally figured out how to reset the manual release: Once the power struts have the hood just about closed, push it down to manually to latch it. The retractor motor spins until it hits resistance, reverses as normal, and is magically reset. After that I played with both the power functions and manual release a few more times, just to verify the proper operation and reset.

In hindsight, I think I recall a kink in the release cable at the motor when I first installed it, but I never tested it (big mistake!) because Hansshow's instructions tell you not to pull it; implying that it's some sort of one-time use thing. It's not.

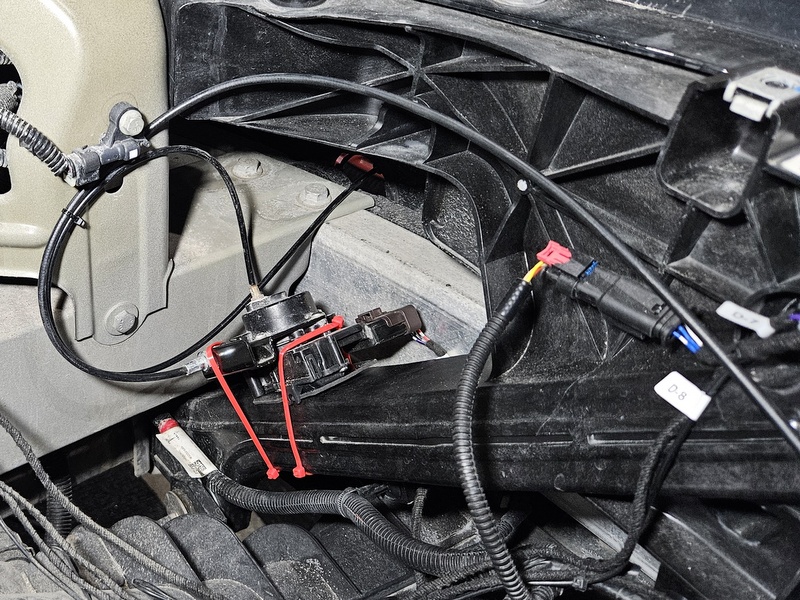

So now it was time to pull the frunk tub and put everything back together. Without more of the giant zip ties that came with the kit, I combined what was to hand and took extra steps to ensure that the manual release cable was not kinked:

When I first installed the kit I didn't use the double-sided tape pads Hansshow provided, as the motor is such an irregular shape that I didn't think it would do any good. This time there's a big piece under the motor so it can't slide down that diagonal bar to kink the emergency pull against the shotgun. (The gap there's bigger than it looks in the photo above). I didn't think to do it at the time, but when I have it apart again in spring to replace those red zip ties with beefier ones, I'll also lube the release cable with high viscosity oil. I've used it in the past to unjam grip-shifter cables on kids bikes, and it really gets in there from end to end. It should help prevent internal corrosion, and hopefully make the cable even easier to pull. (It's already pretty good now that the kink's out of it.)

Before buttoning everything back up I tested it a few more times, including pulling the release in its final position behind the emergency access hole in the bumper. With everything good, I got it back together, then took it through the car wash for the wife because of all my hand prints in what TeslaBjörn calls the winter salts-schmutz-fest. (Who expects a 15-minute line up at the car wash after midnight?!) She doesn't fully trust it yet (and I can't say that I blame her), so hasn't put anything back into it. We do cycle it every few days though to make sure that it still works, and hopefully our trust will return over time. It was certainly a brilliant and highly useful feature for those first couple of months.

Looking back, I wasted a lot of time under the car (and unfastened a lot of garnishes, clips, and bolts) that I didn't need to. If this happens again, I'm pretty sure that I can snip the zip ties and access the retractor motor from just the driver's side fender without even pulling the entire liner, and I made sure to leave enough slack in the wiring for that with the motor in its new position. Hopefully things won't come to that again, but we'll see.

TLDR: I still don't know why the retractor jammed, but the emergency release works if you're careful to install it without any kinks, and we got our power frunk back. I'd also suggest lubing the emergency release cable with a high viscosity oil to prevent internal corrosion.

Last edited:

Similar threads

- Replies

- 17

- Views

- 4K

- Replies

- 0

- Views

- 668

- Replies

- 27

- Views

- 2K

- Replies

- 0

- Views

- 114