Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel Spacer issue, please read!!!

- Thread starter BasharMousa

- Start date

Moving the offset to counter additional overall width when done correctly merely adds width to the outside without removing it from the inside.

This moves the centerline of the wheel out further from where the steering geometry wants it to be located.

You're putting more meat down on the road on the outside steering edge and less on the inside.

Interesting that you think sunken wheels provide an aerodynamic advantage. Why then when manufacturers add wheel well covers do they make them flush with the body panels? Why do trucks place the trailer as close to the cab as possible to decrease the gap and thus less drag?

I think I believe Tesla when their designer was talking about this and the pains they went through to get the car slippery. Slightly sunken is better than flush. Their wind tunnel is much better than mine

EVSteve

110% Solar Powered

This moves the centerline of the wheel out further from where the steering geometry wants it to be located.

You're putting more meat down on the road on the outside steering edge and less on the inside.

As long as none is removed from the inside then the contact point from centerline is widened. The problem occurrs when the wheel is pushed out without widening the wheel. Picture a wrench on a nut. Placing a wrench on one side I enact more torque the further out from center I grip the wrench but that turn wiill place stress at the contact point. If I put a second wrench on the opposite side I can apply more torque while balancing the direction of stress.

I am widening the overall wheel width (not just moving the offset) I have essentially the same centerline. The problem occurs when the width is the same and pushed out (one wrench) which places uneven stress on bearings and higher stress on components. Spacers imo are unsafe as they move the offset without widening the wheel to maintain the distance from center to the inside edge.

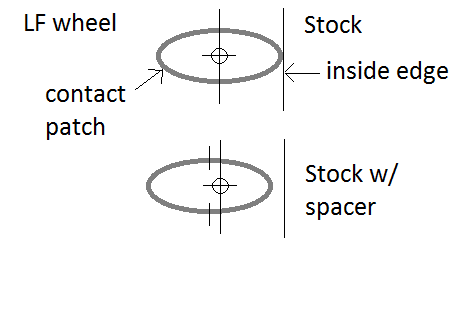

I think a couple diagrams would help show it better, try these out.

The ovals are contact patches. The "target shape" in the middle of the oval is turning axis reference point. Stock setup is the wheel (at top). Most notably the wheel centerline is aligned with steering pivot. Below that shows what happens by tossing in a spacer - the wheel centerline shifts out from the car.

The distance between that centerline and steering axis is a lever creating new stress that suspension has to deal with. The ball joints feel it as extra pull away from the car on the bottom ball, and extra push into the car on the top ball. The spacer and lugs feel it too, and in the case of this thread started to snap.

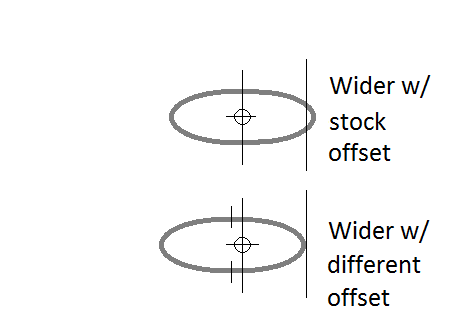

Next diagram shows widening the wheel (and rubber) creating a wider contact patch. The top one shows picking a wheel and spacer pairing that maintains stock offset (40mm) from hub face. For example, picking a wheel that has +40 offset (stock) and no spacer. Or picking a wheel that has +50 and adding a 10mm spacer. These have the same net result of keeping steering axis reference point maintained with centerline, so no new stresses created on suspension. Yes, more rubber fills out wheel well width so if you want that effect and the wider wheels don't hit anything on the inside edge, this is the most stress-free way of doing it.

The bottom setup shows taking a wider wheel (and rubber) and shifting it out with extra spacer to maintain stock inside edge. You might need to do this to help the wider wheel from rubbing on suspension components. (To get this kind of alignment, the extra spacer thickness would be half of the difference of new rubber width minus stock rubber width). Doing this moves the wheel centerline out from the car away from the steering axis and creates those same new stresses already mentioned above, just the same as shifting a stock wheel out with spacers.

Anytime you shift the centerline by not keeping the stock offset to hub distance constant, new stresses are created. This is independent of chosen wheel width.

The ovals are contact patches. The "target shape" in the middle of the oval is turning axis reference point. Stock setup is the wheel (at top). Most notably the wheel centerline is aligned with steering pivot. Below that shows what happens by tossing in a spacer - the wheel centerline shifts out from the car.

The distance between that centerline and steering axis is a lever creating new stress that suspension has to deal with. The ball joints feel it as extra pull away from the car on the bottom ball, and extra push into the car on the top ball. The spacer and lugs feel it too, and in the case of this thread started to snap.

Next diagram shows widening the wheel (and rubber) creating a wider contact patch. The top one shows picking a wheel and spacer pairing that maintains stock offset (40mm) from hub face. For example, picking a wheel that has +40 offset (stock) and no spacer. Or picking a wheel that has +50 and adding a 10mm spacer. These have the same net result of keeping steering axis reference point maintained with centerline, so no new stresses created on suspension. Yes, more rubber fills out wheel well width so if you want that effect and the wider wheels don't hit anything on the inside edge, this is the most stress-free way of doing it.

The bottom setup shows taking a wider wheel (and rubber) and shifting it out with extra spacer to maintain stock inside edge. You might need to do this to help the wider wheel from rubbing on suspension components. (To get this kind of alignment, the extra spacer thickness would be half of the difference of new rubber width minus stock rubber width). Doing this moves the wheel centerline out from the car away from the steering axis and creates those same new stresses already mentioned above, just the same as shifting a stock wheel out with spacers.

Anytime you shift the centerline by not keeping the stock offset to hub distance constant, new stresses are created. This is independent of chosen wheel width.

Last edited:

EVSteve

110% Solar Powered

Even your drawing shows the wider patch providing the same base despite the slight shift in centerline. Assuming your theory is correct then explain why after 12,000 miles with factory alignment my tires are not showing accelerated wear on the inside edge. If pressure was being exerted off centerline then more wear would be shown on that side. I even run the car with air suspension lowering brackets in the low setting often which based on other cars should make inside edge wear even worse.

Last edited:

explain why after 12,000 miles with factory alignment my tires are not showing accelerated wear on the inside edge.

Your suspension is well aligned with not too much negative camber.

Shifting wheels out with spacers does not change camber.

EVSteve

110% Solar Powered

EVSteve

110% Solar Powered

Your argument is increased stress on components. If more pressure is being exerted at an odd angle it will show up in tire wear. I had a feeling the camber argument would get shoved into this. Unless I have a camber setup to balance the pressure offset wear would be shown. I have not and do not.

If pressure was being exerted off centerline then more wear would be shown on that side.

I think as long as camber is reasonable you'd have even wear, regardless of extra / added offset.

There's a couple of different kinds of forces exerted... static and dynamic. Statically (not rolling) the suspension doesn't care where you've located your centerline... the load bearing weight of the car is felt "from the hub" up through the suspension. Just sitting there, any wheel that doesn't have zero offset will be experiencing a torque at the interface between the wheel and hub face, the mounting gear will feel this. Add offset and add even more offset with spacers and this torque increases. Stressing the mounting gear. A 40 offset on model S warrants heavy lugs @ 129 ft-lb torque spec for a reason... its a heavy car and that's a good chunk of offset. So any offset at all is strike one for busting lugs.

Add dynamic forces, now the car is rolling and hitting bumps. Even weight distributed over the contact patch, and you hit a speed bump, the whole wheel moves up as a whole absorbed and aligned by suspension. But now zoom in on the interface between wheel and hub and notice the extra offset acts as a lever multiplying the stress that the extra bump pressure to what was already being experienced at the point. Lugs are now outside of their natural habitat of tolerance. PLUS the whole upward hit is arriving at the suspension at a place outside of where the ball joints were placed to expect the hit, acting like a lever there too, putting pressure on them.

The point of this thread is impact to the hard components created by shifting offset. Even tire wear is no assurance that these forces are not happening.

Last edited:

SSedan

Active Member

I have to wonder if the nuts came a little loose. Could be studs weren't seated, studs stretched etc., Tiny bit of slack will start breaking things.

Far as aerodynamics of flush vs inset, comparing tractor trailer and skirts is not a thoughtful argument because those aren't rotating wheels with their own airflow.

Far as suspension stress and geometry, these parts are not at the ragged edge of design limits, spacers are safe if done right and maintained in the form of checking torque.

Far as aerodynamics of flush vs inset, comparing tractor trailer and skirts is not a thoughtful argument because those aren't rotating wheels with their own airflow.

Far as suspension stress and geometry, these parts are not at the ragged edge of design limits, spacers are safe if done right and maintained in the form of checking torque.

Hello all and sorry for the update delay.

Today the car went to SC to het some work done and as the tech was taking of the front wheel another stud broke from the front spacers, so now these are off.

Here is a picture of the wheel from the inside please note the marks the original studs left on the wheel.

It apears like my 19mm spacers are not wide enough from the original turbines to clear the orginal tesla studs.

Pictures are sent to vendor and awaiting feed back.

Today the car went to SC to het some work done and as the tech was taking of the front wheel another stud broke from the front spacers, so now these are off.

Here is a picture of the wheel from the inside please note the marks the original studs left on the wheel.

It apears like my 19mm spacers are not wide enough from the original turbines to clear the orginal tesla studs.

Pictures are sent to vendor and awaiting feed back.

davidc18

Active Member

thanks for the update and the photos. I have 20 mm spacers and will have to take the wheels off to check for any similar markings.

The picture you posted of the studs hitting the back of the wheel I think is the most valuable lesson learned in this whole thread. Good piece of detective work that was, flipping the wheel over to have a look!

Whether studs hit or not probably depends on wheel style and maybe even lot-to-lot variance of wheel castings. Bottom line: always check after mounting, maybe even after rotating tires. Pop them off the car and have a look see for hits.

Whether studs hit or not probably depends on wheel style and maybe even lot-to-lot variance of wheel castings. Bottom line: always check after mounting, maybe even after rotating tires. Pop them off the car and have a look see for hits.

In my opinion, there is no such thing as a properly installed and torqued spacer. You have two surfaces instead of one, which causes looseness after a bit of vibration. In addition, you've changed the centerline of the tire from the OE setting which puts additional stress on the suspension and wheel bearings. I've seen too many vehicles that rolled over because spacers were used. A Tesla is most immune to rollovers, but not to other damage. Scottm is spot on.Bought a set of 19mm spacers to fit in May 2018. Spacers where installed and torqued properly mid Jun 2018.

thanks for the update and the photos. I have 20 mm spacers and will have to take the wheels off to check for any similar markings.

so do your 20mm spacers clear the 21 turbines?

davidc18

Active Member

Hi Fellow Model S owners,

Ive been a member of this forum for almost a year now but mostly a reader and haven't contributed nor posted any thread before.

Today i feel that i need to post this for all owners running spacers on their model S, 21” rims in particular as this is what i have.

I own a 2013 P85 running 21” wheel non-staggered. Bought a set of 19mm spacers to fit in May 2018. Spacers where installed and torqued properly mid Jun 2018.

View attachment 334918 View attachment 334919

Today early morning ive noticed a weird noise, metalic scrapping, from the rear left wheel so i pulled over and inspected the car but found nothing to report. On my second drive i noticed the sound had become more pronounced, so again i pulled over and tried to shake the wheel and thats when a lug nut fall on the ground. Lucky enough i was less than 10 minutes away from a tire shop, took off both rear wheels to find out that the spacer studs are snapped

View attachment 334895 View attachment 334896

View attachment 334897

As you can clearly see the rear left spacer has one stud broken and resting within the lug nut. Right side had 3 studs broken as we removed the lug nuts.

Now this is my daily car that i drive atleast 150-200km a day with my family inside. I cant imaging what wouldve happened if i lost more studs and wheel came off. I am glade that i noticed it early enough to prevent and harmful damage.

I have sent the manufacturer an email, and i will not disclose their name yet as i will give them the chance to justify/explain the reason for such issue to happen. But the main purpose of this thread is for all owners with spacers to check their setup thoroughly and periodically as this is extremely dangerous.

Similar threads

- Replies

- 22

- Views

- 2K

- Replies

- 18

- Views

- 2K

- Replies

- 5

- Views

- 1K

- Replies

- 7

- Views

- 2K