I think the 2170 is the second generation cell that you see now and there will be a third. Tesla is pushing for a cobalt free cell. The 2170 has less cobalt than the 18650. The supply of cobalt is the Achilles heel of battery production. Permits for a Lithium mine has been applied for near the Gigafactory and nickel is in abundance. The top Cobalt producing countries are the Congo, Russia, Australia, Canada, Cuba and the Philippines. The Congo is the top producer at 64,000 metric tons. With more and more EVs being made it would make sense to eliminate cobalt from the cell with the top producers are unstable countries.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think the 2170 is the second generation cell that you see now and there will be a third. Tesla is pushing for a cobalt free cell. The 2170 has less cobalt than the 18650. The supply of cobalt is the Achilles heel of battery production. Permits for a Lithium mine has been applied for near the Gigafactory and nickel is in abundance. The top Cobalt producing countries are the Congo, Russia, Australia, Canada, Cuba and the Philippines. The Congo is the top producer at 64,000 metric tons. With more and more EVs being made it would make sense to eliminate cobalt from the cell with the top producers are unstable countries.

As has been stated who knows how many times in this and other threads, the size of the cell has nothing to do with its composition. There's no reason that the same chemistry cannot be put in the 18650 s as in the 2170 s. Packaging is important, but not the most important thing. The 18 650 can be updated.

It's likely that the production processes are very different with the new chemistry so the change in chemistry would require investments. Maybe Tesla has a contact to take the production for X years and they are waiting for it to expire before they transition to the new cells that are gonna have better costs since they've payed for the building at GF1.

As a matter of production efficiency, it seems more streamlined to invest in a S/X pack redesign so that you can use the same cell size and chemistry for all products.As has been stated who knows how many times in this and other threads, the size of the cell has nothing to do with its composition. There's no reason that the same chemistry cannot be put in the 18650 s as in the 2170 s. Packaging is important, but not the most important thing. The 18 650 can be updated.

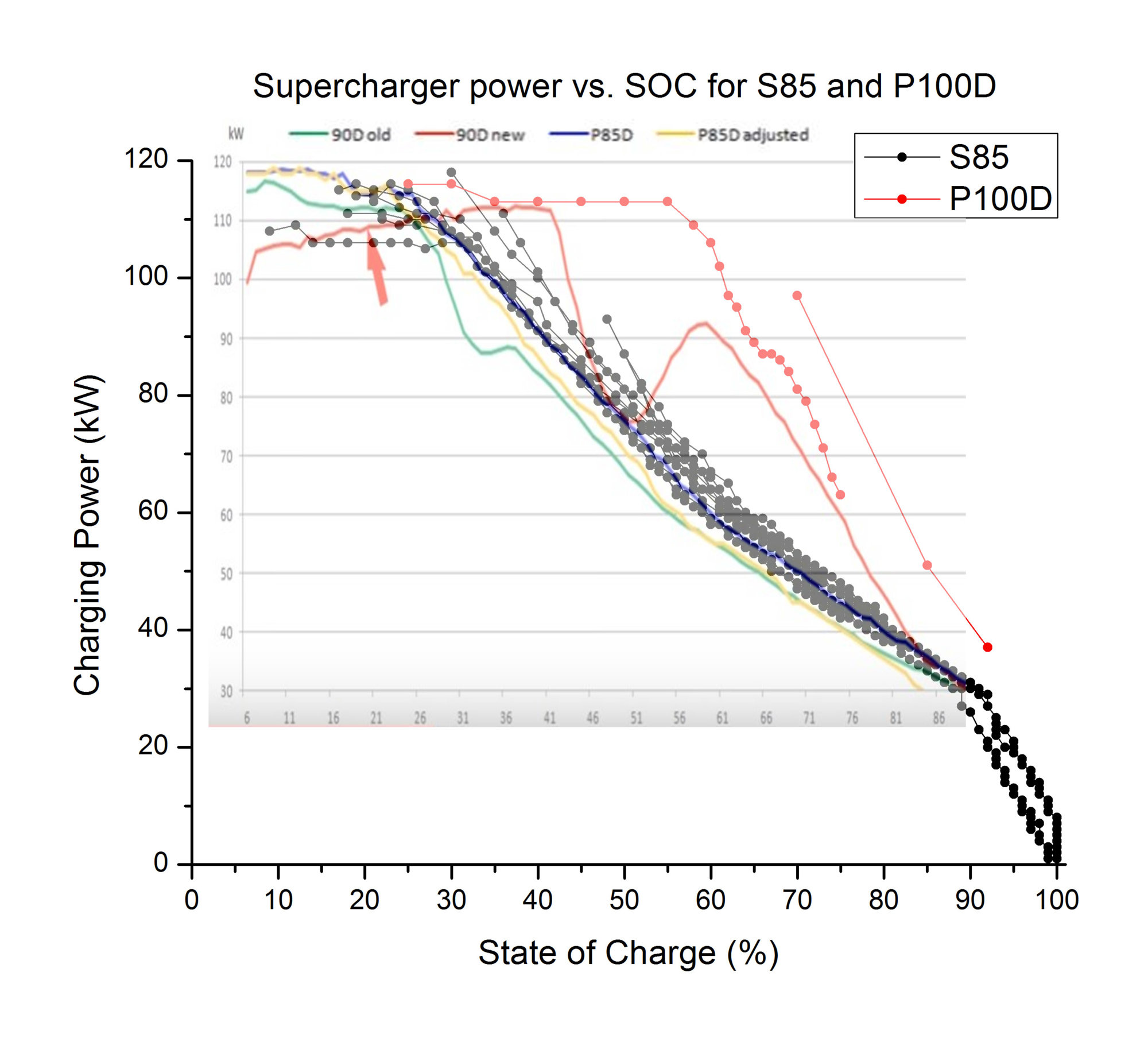

I think the interesting position they'll be put in is that the new packs on the 3 appear to be capable of charging at 1.5C vs. 1C on the 100 packs. Supercharging is going to be faster on the 3 than on the S/X with the old cells.

The 100KWh packs seem to get the same near-120KW peak on superchargers that other cars do... so almost 1.2C. given that the 75KW packs can do about the same and that's ~1.6C

There's some likelihood that the current superchargers and/or cabling are the limiting factor.

Now that's not to say that the new 2170 cells don't also have some superior ability, but I'm just not sure that any 100KWh pack, regardless of composition, is going to see much better on current gen superchargers...

Last edited:

Sorry, I wasn’t clear. The 100D packs sit near 1C at 50% SOC. The LR 3 packs are at 1.5C at the same point. The taper gets pushed back significantly with the new packs.The 100KWh packs seem to het the same near-120KW peak on superchargers that other cars do... so almost 1.2C. given that the 75KW packs can do about the same and that's ~1.6C

There's some likelihood that the current superchargers and/or cabling are the limiting factor.

Now that's not to say that the new 2170 cells don't also have some superior ability, but I'm just not sure that any 100KWh pack, regardless of composition, is going to see much better on current gen superchargers...

As a matter of production efficiency, it seems more streamlined to invest in a S/X pack redesign so that you can use the same cell size and chemistry for all products.

Agreed. The title of this thread indicates my belief that they will in fact standardize on 2170 size cells. The problem is that the demand for Tesla products that use the 2170 form factor, and thus the equipment that produces it, is much, much higher than Tesla anticipated. So, I thin, they pushed back the conversion of their flagship vehicles perhaps some months yet. Hopefully not much more than a year.

They're also fighting the need for profitability. Replacing the 18650 equipment, or upgrading it if possible, will cost a lot. Tesla and Panasonic could do it together, but it would push out of the time when Tesla shows overall positive cash flow.

Ah, I see.Sorry, I wasn’t clear. The 100D packs sit near 1C at 50% SOC. The LR 3 packs are at 1.5C at the same point. The taper gets pushed back significantly with the new packs.

This seems to indicate it steps down from about 117KW to ~112KW at about 40% and holds it there til about 60%. The other 100 in that chart seems to be close to 100KW when starting at about 75% SOC.

If the taper on the 3 is much better I wonder how much of it is thermal variance between sessions vs. pack/cell capability differences?

There is a little discussion starting here. Seems like it may not merely be cell chemistry but also the pack’s thermal properties. No way to be certain but the data do seem to indicate that the new packs can take more power longer.Ah, I see.

This seems to indicate it steps down from about 117KW to ~112KW at about 40% and holds it there til about 60%. The other 100 in that chart seems to be close to 100KW when starting at about 75% SOC.

If the taper on the 3 is much better I wonder how much of it is thermal variance between sessions vs. pack/cell capability differences?

Agreed. The title of this thread indicates my belief that they will in fact standardize on 2170 size cells. The problem is that the demand for Tesla products that use the 2170 form factor, and thus the equipment that produces it, is much, much higher than Tesla anticipated. So, I thin, they pushed back the conversion of their flagship vehicles perhaps some months yet. Hopefully not much more than a year.

They're also fighting the need for profitability. Replacing the 18650 equipment, or upgrading it if possible, will cost a lot. Tesla and Panasonic could do it together, but it would push out of the time when Tesla shows overall positive cash flow.

The new cells are at GF1 and Panasonic handles cell production and the cost of the machines, Tesla handles the building and an empty shell is not that much.

For 18650 it's all Panasonic and they make those in Japan.

Demand for 2170 cells is well behind schedule as Tesla messed up the M3 production so Panasonic had to adjust down and this is not gonna be something that delays an update. Panasonic has been rather annoyed by the Tesla delays as it their profitability.

Some more discussion about the C rate differences here:

Is Tesla Shipping Model 3 With 2X Model S P100D Supercharging C Rate?

A little circular since it references the thread I linked earlier, but worth posting, I think.

Is Tesla Shipping Model 3 With 2X Model S P100D Supercharging C Rate?

A little circular since it references the thread I linked earlier, but worth posting, I think.

Sorry, I wasn’t clear. The 100D packs sit near 1C at 50% SOC. The LR 3 packs are at 1.5C at the same point. The taper gets pushed back significantly with the new packs.

For the (de)charging power relative to the capacity, I would really prefer if we could use C-rate, and reserve C for the actual charge stored in the battery. In the above statement (especially with the inactive 'sit') 1C would naturally be interpreted as 1 Coulomb, although given the context and the actual numbers it is clear that C-rate is what is meant.

Also because Tesla doesn't have any spare 2170s. All of them are going to the Model 3 ramp up, the Tesla Semi, and the upcoming roadster. We're not likely to see an S/X refresh until after the roadster comes out if I had to bet.

Current production ramping notwithstanding I would be surprised if the dimensioning of the Gigafactory had left out the projected battery capacity needed for coming versions of the Model S/X.

.....

What pack would a future S/X/ full size pickup use?

.......

A 200 kWh 2020 Roadster pack would be nice.

Very nice.

GSP

The new cells are at GF1 and Panasonic handles cell production and the cost of the machines, Tesla handles the building and an empty shell is not that much.

For 18650 it's all Panasonic and they make those in Japan.

Demand for 2170 cells is well behind schedule as Tesla messed up the M3 production so Panasonic had to adjust down and this is not gonna be something that delays an update. Panasonic has been rather annoyed by the Tesla delays as it their profitability.

As earlier, the source of your data would be helpful. Much of what you are saying is exactly the opposite of what I've read.

Additionally I believe pack production is at least as intensive as cell production and, to quote one of the gurus, the Model 3 pack is a work of art.

dhanson865

Well-Known Member

Tesla claimed in a results call ( likely Q4) that they are limited to 100k units for S&X this year because they would need a substantial redesign for the new cells. Don't have a clue where to find a transcript to provide a quote anymore but you can try finding one.

I remember that differently. I heard it was because the space / assembly lines / machinery assigned to S/X are limited to 100k units period, for all time. Not just this year but all years in the past as well. They aren't going to change that production limit because they don't think that demand is high enough to warrant changing all those line sections to increase production.

edit: 27 mins in Q4 Q&A, https://edge.media-server.com/m6/p/iufenmyd

JB says not worth the risk of increasing battery supply...

Elon says (paraphrased as I typed this while he was talking and didn't want to pause and rewind and play a hundred times over to get it exact, and I want you to understand his implied points so I'm rewording some on purpose):

- if you increase the number of 18650s then all the other portions (entire supply chain) have to adjust to match so either you have to overhaul the manufacturing process for S/X (capital expenditure) or you end up with people working overtime (affects gross margin). You design the manufacturing machine for a set rate and to increase that you either redesign the manufacturing machine or run it at red line.

essentially implying that isn't going to happen any time soon. Too busy working on model 3 to redo the high profitability manufacturing lines.

edit2: your post implies a redesign of the car being the issue, the real issue is the redesign of the factory not the car.

Last edited:

dhanson865

Well-Known Member

I think the interesting position they'll be put in is that the new packs on the 3 appear to be capable of charging at 1.5C vs. 1C on the 100 packs. Supercharging is going to be faster on the 3 than on the S/X with the old cells. Hard to know if enough people will care or notice, but it matters a bit to me. If they put new cells and packs in the X that are capable of faster Supercharging, I'm likely to be in line for a new one. Of course, that assumes a bit of extra capacity as well.

I find it funny to hear that old packs are doing 1C for multiple reasons

1. If they do 115 or 120 peak they are doing 1.15C or 1.2C

2. older cars did much higher peaks in terms of C

some can charge at 105 KW (60 KWh with older battery pack, 1.75C charge rate)

some can charge at 111 KW (60 KWh with newer battery pack, 1.85C charge rate)

some can charge at 120 KW (85 KWh B, D, or E battery pack, near 1.41C charge rate)

remember those? Old school packs from back in the day charged at near 1.85C at peak. I don't see ~1.5C on the Model 3 as ground breaking (and I haven't paid attention close enough to do the math to see if they got the 1.5 right).

I clarified afterwards that I was talking about at 50% SOC. Either way, it's the area under the curve that matters most.I find it funny to hear that old packs are doing 1C for multiple reasons

1. If they do 115 or 120 peak they are doing 1.15C or 1.2C

2. older cars did much higher peaks in terms of C

some can charge at 105 KW (60 KWh with older battery pack, 1.75C charge rate)

some can charge at 111 KW (60 KWh with newer battery pack, 1.85C charge rate)

some can charge at 120 KW (85 KWh B, D, or E battery pack, near 1.41C charge rate)

remember those? Old school packs from back in the day charged at near 1.85C at peak. I don't see ~1.5C on the Model 3 as ground breaking (and I haven't paid attention close enough to do the math to see if they got the 1.5 right).

Similar threads

- Replies

- 5

- Views

- 401

- Replies

- 10

- Views

- 806

- Replies

- 2

- Views

- 358

- Replies

- 7

- Views

- 1K