Could be a great Christmas gift for some of us! To me, from me. This is the one I've been waiting for, I know it'll be well worth the wait!

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

tomp

Member

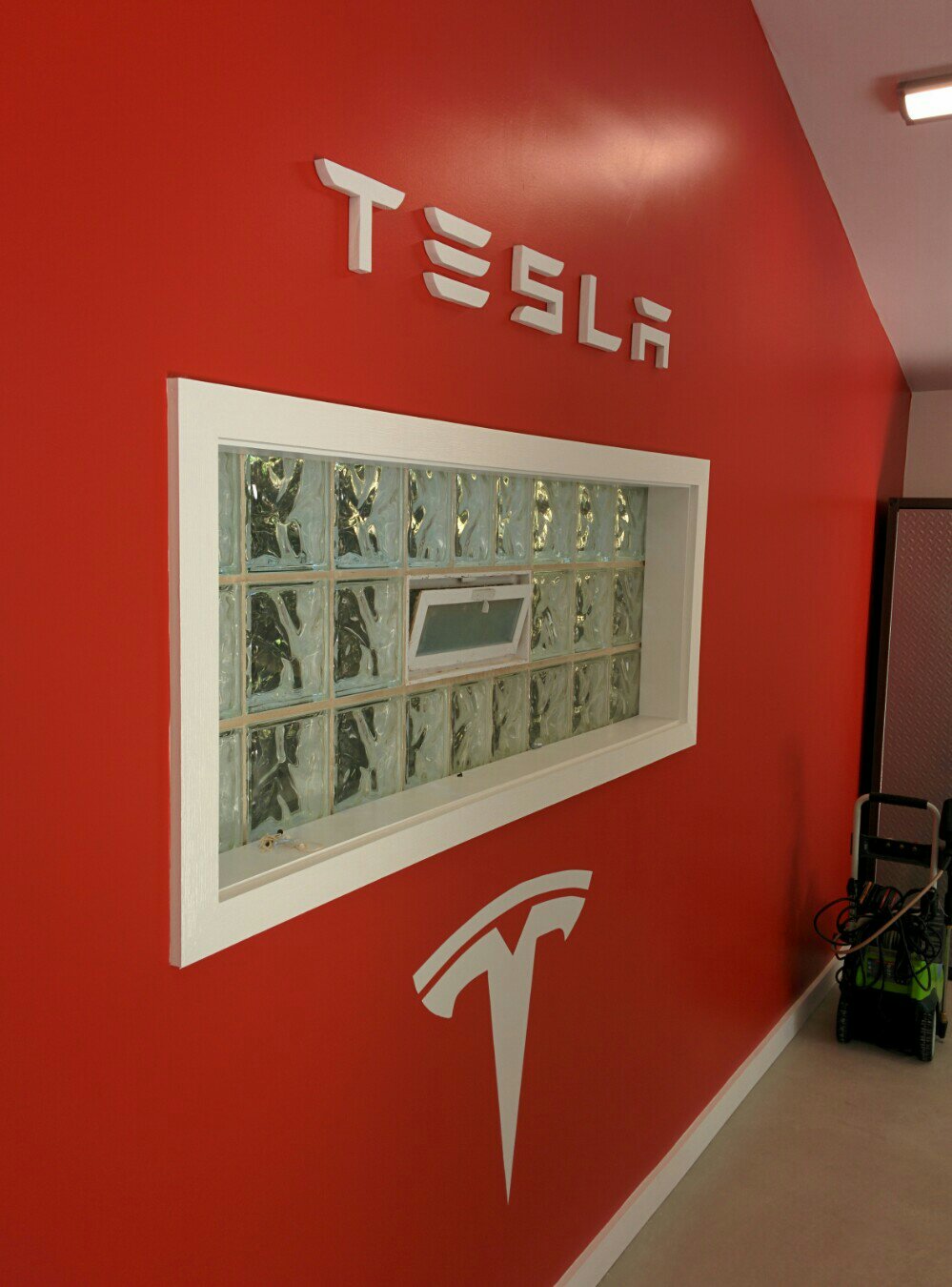

That is an incredible garage!

I wonder if there is a difference between the PC TTF and the Mac TTF. I purchased the font package as well. I noticed that the "S" is grabbed from the Emblem Bold C (I think) package and the letters in general did not appear to have the same height as the font Tesla uses.

Did you notice this as well? I wonder if there are clear differences in the PC/Mac versions.

For example, these letters in my garage were printed and cut from David's font but seem to be slightly different from the actual Tesla font.

I wonder if there is a difference between the PC TTF and the Mac TTF. I purchased the font package as well. I noticed that the "S" is grabbed from the Emblem Bold C (I think) package and the letters in general did not appear to have the same height as the font Tesla uses.

Did you notice this as well? I wonder if there are clear differences in the PC/Mac versions.

For example, these letters in my garage were printed and cut from David's font but seem to be slightly different from the actual Tesla font.

David told me when I talked to him that Tesla's designers/art department may have made a few modifications in the way the font was used. As I don't have the PC version I can't determine if there are differences. But I guess I'll find out when the laser cutting begins.

RLA12194

Member

Any updates?

I should have the appliqués with the letters cut out by the end of the week. LAI is a few weeks behind schedule. Once I have them work will begin on the 3D printing for the letters and the lighting. I probably won't have a working prototype until the new year.

I starting to get more that a bit ticked off LAI. They told me the work would be completed last week and nothing has happened. They have about $2,000 worth of appliqués. This work was supposed to be completed by the end of October. Not good. And this is a large company that serves the aerospace industry. I suppose this project is small potatoes and not a priority.

Last edited:

That's frustrating...

LAI let me know yesterday that the appliques will ship tomorrow. Once I receive them I'll begin working with the 3D printing company to make and light the 3D T E S L A letters that will be fitted into the cut out letter spaces. I'm guessing we're now about 5-6 weeks away from a working model that I can install on my car and make available to others. I won't know costs until we have the 3D printing and light source worked out.

Rick, here is a idea, which might be too late to work into this project, or too complicated.

I believe you will have the letters brighten with the brake lights. What about also to the turn signals...have each letter individually controlled, and brighten from left to right. and right to left for each directional signal.

Just an idea I had.

I believe you will have the letters brighten with the brake lights. What about also to the turn signals...have each letter individually controlled, and brighten from left to right. and right to left for each directional signal.

Just an idea I had.

How did the appliques look when you got them, Rick? @NJ's idea is awesome but would definitely take more complicated control circuitry and control over individual letters which is likely the hard part...

Regrettably they haven't been delivered yet. I think LAI is incredibly undependable. Perhaps that's what happens when a company becomes a defense contractor. They get into very bad habits, like not delivering anything to customers on time.

- - - Updated - - -

Rick, here is a idea, which might be too late to work into this project, or too complicated.

I believe you will have the letters brighten with the brake lights. What about also to the turn signals...have each letter individually controlled, and brighten from left to right. and right to left for each directional signal.

Just an idea I had.

The letters will brighten with the brake lights.

The direction indicator is an interesting idea but will require a different lighting method. Have to think about that one.

The appliqués were shipped today. The hold up was the method used to cut out the T E S L A letters. Laser was tried first, resulting in destruction of one appliqué. Then water jet was used with great results. Seven appliqués were shipped to me and I should have them by week's end.

In the meantime here are a few photos sent to me by LAI. It looks perfect for development of the 3D printed inserts.

The next step will be to 3D print the letter inserts our of transparent material then figure out a way to light them all. That should go much faster than the cut-out work. Not sure if I'll do more than 7, but that will depend on how things go from hear. Certainly LAI is now set up to do more.

In the meantime here are a few photos sent to me by LAI. It looks perfect for development of the 3D printed inserts.

The next step will be to 3D print the letter inserts our of transparent material then figure out a way to light them all. That should go much faster than the cut-out work. Not sure if I'll do more than 7, but that will depend on how things go from hear. Certainly LAI is now set up to do more.

Rick that looks great! Looking forward to the next step! Was it my applique that was ruined by laser?

No, it was some unnamed other person's

The seven appliqués arrived today. The letter cutouts are perfect as perfect can be. Let the work on lighting begin!

I'll make frequent reports on progress. Now that I'm confident we can do the cutouts at the level of quality necessary, once the original seven are completed and delivered, we can expand production to meet any level of demand.

I'll post some photos tomorrow, some with the lighting effect simulated.

I'll make frequent reports on progress. Now that I'm confident we can do the cutouts at the level of quality necessary, once the original seven are completed and delivered, we can expand production to meet any level of demand.

I'll post some photos tomorrow, some with the lighting effect simulated.

Immobilized today with the flu so I spent some time on the web searching for way to light the appliqué. The effort was rewarded. I found a white light flat strip LED module that's only 2mm thick with a color temp of 6500K. Two will be required for each appliqué. They have soldering pads and are rated for 9-10v DC which will require one resistor to step down the 12 volts from the car. I ordered a bunch for testing and should have them in a week.

Work on the 3D letter inserts starts Monday so I expect to have an operating version for installation on my car in about a month.

I took a bunch of shots of the appliqué lit from behind with flashlights. While it looked pretty cool in person the camera images were not the greatest. Here's my best attempt:

Work on the 3D letter inserts starts Monday so I expect to have an operating version for installation on my car in about a month.

I took a bunch of shots of the appliqué lit from behind with flashlights. While it looked pretty cool in person the camera images were not the greatest. Here's my best attempt:

Last edited:

Similar threads

- Replies

- 23

- Views

- 7K

- Locked

- Replies

- 8

- Views

- 3K

- Article

- Replies

- 46

- Views

- 11K

- Replies

- 4

- Views

- 12K

- Replies

- 52

- Views

- 33K