What will make-up the first gen 3 exterior structure? Likely to be a "Model 2" hatchback.

Single choice

No changing

Anonymous

No peaking

Closes in 1 week

Boring Co vehicle style would count as glass:

This would count as plastic:

DeLorean panels are 0.8mm

Gigacast outer would be a first

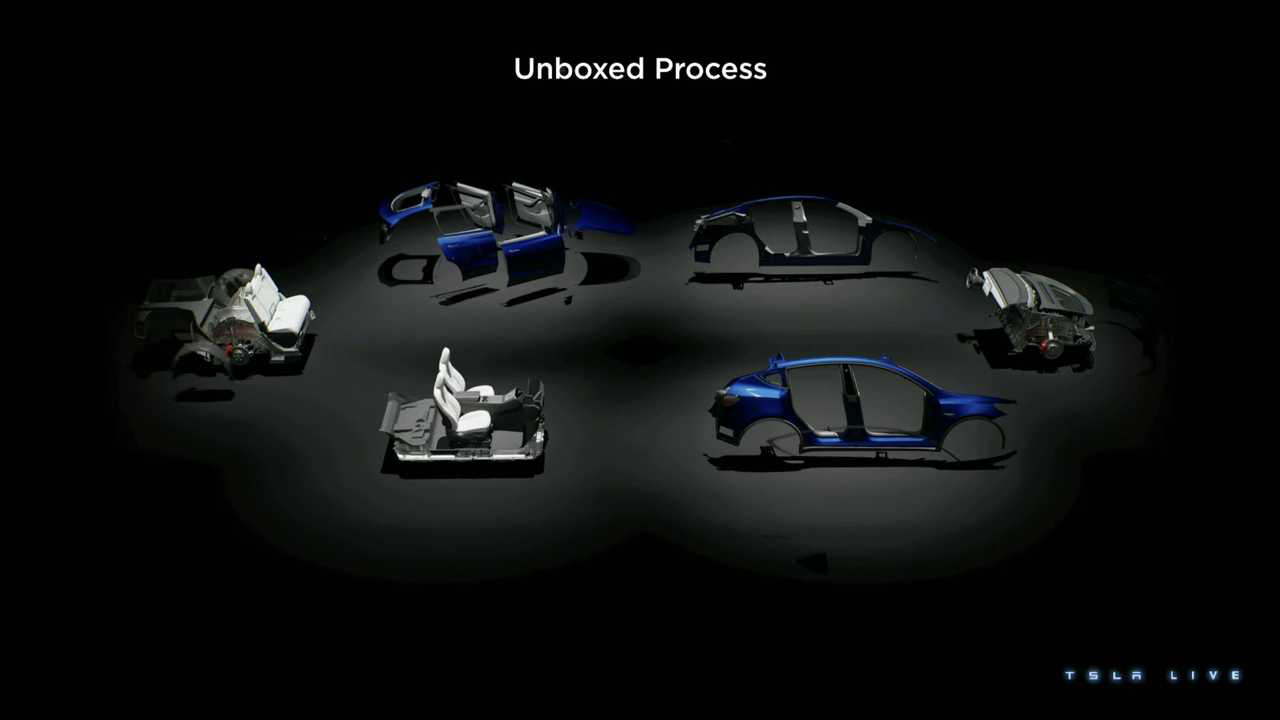

Unboxed pictures suggested traditional shell structure.

Silhouette suggests not glass or thick stainless:

“Yeah. Just to be clear, it will be cool, but it’s utilitarian. It’s not meant to, you know, fill you with magic. It’s to get you from A to B. It will still be beautiful, but it’s utility,” shared Elon Musk.

Single choice

No changing

Anonymous

No peaking

Closes in 1 week

Boring Co vehicle style would count as glass:

This would count as plastic:

DeLorean panels are 0.8mm

Gigacast outer would be a first

Unboxed pictures suggested traditional shell structure.

Silhouette suggests not glass or thick stainless:

“Yeah. Just to be clear, it will be cool, but it’s utilitarian. It’s not meant to, you know, fill you with magic. It’s to get you from A to B. It will still be beautiful, but it’s utility,” shared Elon Musk.

Last edited: