Because I add the front and rear torques when calculating mechanical power I am assuming the two motors are turning at very close to the same speed, so the two motors are geared the same. The MS owners manual implies this when it claims a single final drive ratio of 9.73:1. I checked this for the rear by calculating the diameter of 245/35-21 tires and calculating MPH per rear motor RPM given 9.73:1. The result is interesting because the RRPM data fits the MPH data very closely after twelve seconds when the car is coasting. During the run, rear motor RPM was 3% too high about two seconds in, followed a curved descent to 1% too high at the end of the quarter mile. In other words, it shows the tire slippage one would expect under hard but decreasing acceleration, where slippage goes slightly the other way once decelerating. It raises the question of how MPH is measured. Personally, I suspect it’s integrated from an accelerometer, which is periodically calibrated against motor RPM when the car is cruising without accelerating.

There's no doubt that big gaps between the rear RPM line and the MPH line indicate tire slip, but I would also love to know the source of the MPH number. I have pondered the paradox of MPH being generating from wheel speed and then using that MPH data for AWD traction control. Duh!

I thought this paradox could only be solved by getting MPH from something other than the wheels. But your theory on wheel speed sensors is very interesting - that MPH is integrated from an accelerator and periodically calibrated against wheel speed when the car is cruising without accelerating.

However, I tend to agree with Mike, that MPH is probably from the front wheels. This works if the power applied to the front wheels is always low enough that they don't slip. The graphs show that when the rear wheels slip, the TC reduces power to all wheels assuming the front wheels might also be slipping. In heavy spin, it even cuts front torque to zero.

Getting data from the chassis CAN bus may lead to more info on this.

I ask for your forgiveness in advance but I’m going to torture you all with some tribology – the physics of friction – as it applies to tires and cars. Of course a tire spins when its grip is overwhelmed by torque, but even when a tire is hooked up and appears to be rolling synchronously with the road there is still some slip whenever torque is being transmitted to the road as either a driving or a breaking force. The slip is only a few percent of the speed of the tire over the ground, but it is still measurable. Here is an interesting academic paper I found on the subject.

View attachment SlmillerGerdesACC.pdf

The topic here is longitudinal slip under torque. There is also lateral slip in a turn, where a car loaded with lateral g forces doesn’t exactly track the angle at which the tires are pointing, even when the tires are not sliding, so the car is not drifting. I bet lolachapcar is familiar with this, since he has experience with racing.

This chart from the attached paper shows how tires slip up to a few percent. Once force increases over the hump of the curve, additional slip provides less traction and the tire breaks free and spins. The point of the paper is to measure slip under acceleration and deceleration, comparing tire speed from its rotation (the speedometer) to car speed from GPS. Here is their chart. When velocity ramps up there is slip one way, when velocity decreases there is slip the other way over a total of about a 3% range of slip.

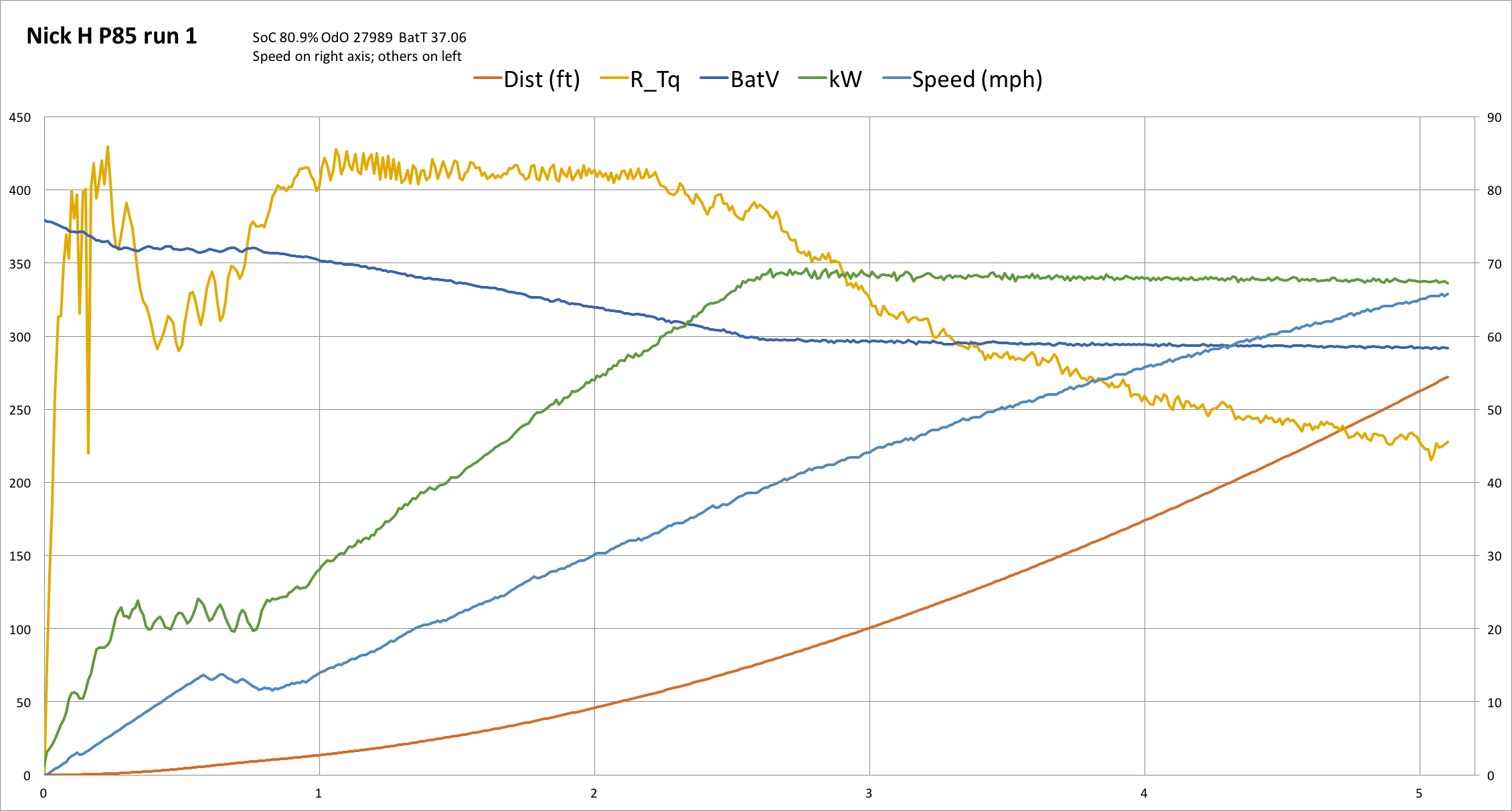

Now here is my chart for rear wheel slip, which I mentioned in my earlier post. This is the same run, where the first 12 seconds are under hard acceleration followed by coasting. There is about a 3% range of slip. The dots going off the chart in the first two seconds are where the tires are sliding or spinning (not yet hooked up) rather than slipping.

Compare with the left half from the chart in the paper. The zero slip axis is about 1% lower than it should be, but that's because I calculated the non-slip rotational velocity based on MPH from the CAN bus, my calculation of tire diameter, and the 9.73:1 gear ratio in the manual. The comparison is with rear motor RPM. The tire calculation in particular is probably the source of the error. The fact that this works at all proves that 9.73:1 is the correct ratio for the rear motor. I wish I could confirm that was correct for the front too: I agree there is room for doubt.

The point of this exercise is that even though the FRONT tires never spin because there is not enough torque, they will still slip by a percent or so during hard acceleration thanks to the torque of the front motor. Thus they do not give an accurate measure of MPH while accelerating. That's why I think the MPH numbers come from integrating an accelerometer rather than measuring any of the tire rotations, which are all slipping while accelerating. And after reading the paper, where the researchers use GPS to measure vehicle speed, I suspect the calibration of the accelerometer integration might also be by GPS. They couldn't just use GPS for speed because there isn't always a good signal. Also (half tongue in cheek) integrating accelerometers and gyroscopes is how you guide rockets (SpaceX) so there might be some experience there.