I'm not arguing exact Cd specs but you can't look at that truck and logically tell me that it wouldn't have a lower Cd if that roof line break weren't so harsh and the wheel well arches weren't more curved that the leading and trailing faces. Regardless of exact wind tunnel Cd numbers that fact can't be disputed. This is exactly the point of the conversation and yet some here who know nothing of aerodynamics aren't even questioning the motive because Tesla can do no wrong and everything they do is right.

This leads to the current state of the conversation being that we can't even bring up the "why" of the design when some people are still convinced that it's 100% for aerodynamics. It's simply not. Once we can admit that we can get into the why and I think that once these same people realize that we could have a more "normal" looking truck that is even more efficient in terms or energy use and aerodynamics we can have a more intelligent conversation about which they prefer. Many right now are stuck on stupid though and convinced that function is coming before form with this design and those of us who want different are choosing form over function which simply isn't the case.

Well you're right that it's not 100% for aerodynamics you're wrong that "we could have a more "normal" looking truck that is even more efficient in terms or energy use" ( aerodynamic efficiency is redundant here as that feeds energy efficiency )

The following are considerations it appears Tesla worked towards

- Durability or toughness

- Range

- Power ( or towing capacity for this conversation )

So to break these down into the design decisions that feed each

-Durability or toughness

-- SpaceX alloy - Using this alloy necessitates the angular panels as it's prohibitively expensive to put in compound bends as you can't stamp it at the thickness they're using as well bending could introduce weakness into the panels

-Range

--Weight reduction by moving to the exoskeleton necessitating the triangular shape and rear sail panels

--Retractible tonneau cover to prevent the bed from catching air

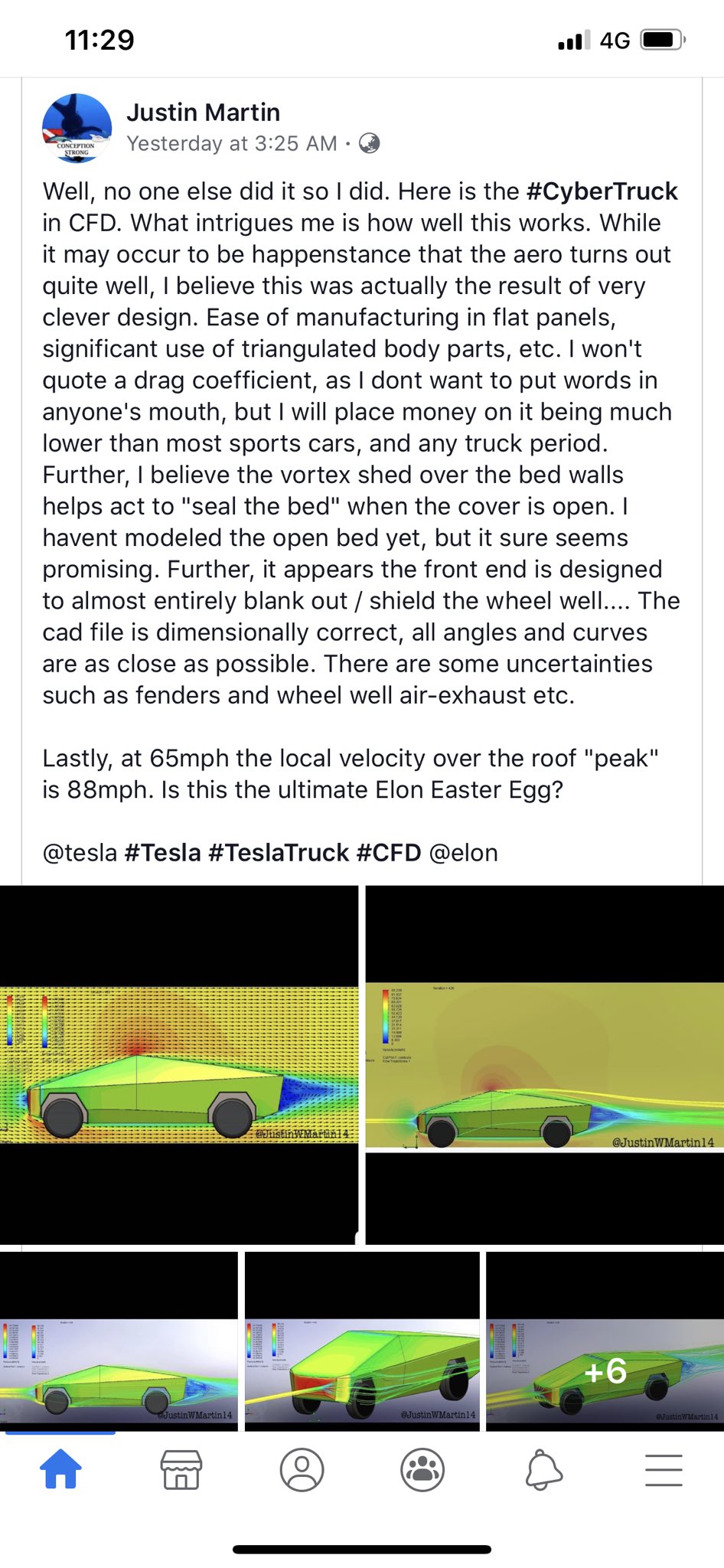

--Aero - within the bounds of the material using "most optimal" shape ( low triangular shape)

-Power

--Weight reduction as above

--Exoskeleton design for body rigidity and make space for higher forward leaning dual stack battery pack

--Adjustable Air suspension

I'm inevitably missing some things here but you couldn't achieve a standard design with the range, power, weight and towing capacity the cybertruck has with existing tech. You'd have to sacrifice something

Example the R1T

- Towing Capacity 11,000lbs

- $69000 starting they haven't even release prices for the mid and high end one

- Range 200mi, 300mi or 400mi ( and the top end one has reduced HP to hit that range)

- Fastest one is 0-60 in 3s