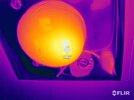

I had to re-use my original one... BUT... I put my FLIR camera to use and I found something perhaps telling... the hottest spot is in the adapter plug, on the positive side. When I pulled the plug and scanned the outlet, that was the same hottest spot... that one very localized area was about 145 degrees F, at the same time the hottest spot on the mobile connector was only 122 degrees. This was measured about 4 minutes after the charging rate dropped from 21 mph to 10 mph, and the amp load from 32 dropped to 16.This is a good point, and if the issue with the connector cable were on the UMC end, it would explain where the heat is. OP, did the second UMC you tried have a like adapter, or did you have to re-use yours?

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

flaky mobile connector charging problem

- Thread starter precisionmike2

- Start date

see below... it could be the adapter or I may have found a problem in the outlet... even though the electrician has checked it twice...Hi All,

The only other "common" item in the tests is the 6-50 connector cable...

I don't imagine the other UMCs had their own 6-50 connector cable.

It could be a defective one...

Shawn

mxnym

Active Member

FYI, I don't think "positive side" is "appropriate terminology" when speaking of AC. Regardless, this definitely sounds like the culprit. Was it always this way, or did it happen after lots of use? Do you unplug and replug frequently? Inexpensive (cheap) outlets aren't necessarily rated for frequent unplugging and replugging, so it is possible the outlet has worn out if the issue is new and you do plug and unplug frequently. Otherwise, it sounds like it could be a faulty outlet (or it could still potentially be the adapter if both are new, not sure how to best validate either one, TBH).I had to re-use my original one... BUT... I put my FLIR camera to use and I found something perhaps telling... the hottest spot is in the adapter plug, on the positive side. When I pulled the plug and scanned the outlet, that was the same hottest spot... that one very localized area was about 145 degrees F, at the same time the hottest spot on the mobile connector was only 122 degrees. This was measured about 4 minutes after the charging rate dropped from 21 mph to 10 mph, and the amp load from 32 dropped to 16.

Hi @precisionmike2,

Was there a reason you chose a 6-50 plug as opposed to the more common 14-50???

The 14-50 is very common at campgrounds in case you are ever nearly stranded.

Electricians may also be more familiar with the 14-50 as it's what most current electric

dryers use...

Keep us posted,

Shawn

Was there a reason you chose a 6-50 plug as opposed to the more common 14-50???

The 14-50 is very common at campgrounds in case you are ever nearly stranded.

Electricians may also be more familiar with the 14-50 as it's what most current electric

dryers use...

Keep us posted,

Shawn

The specifications of any kind of outlet are really clear and simple. I would be drastically worried and wouldn't trust any electrician who would understand a 14-50 but would not understand a 6-50.Electricians may also be more familiar with the 14-50

No, it is not. Dryers only use 30A circuits, so they are either a 10-30 for the older ones up until 1996, or the 14-30 used after that.as it's what most current electric

dryers use...

Hi @precisionmike2 and @Rocky_H,

I made a mistake on the electric dryers.

I meant to say electric range or stove.

14-50 are also one of 2 very common receptacles at campgrounds

for the emergency charge... and for vendors at local festivals and events...

I am still curious about the choice of the 6-50 plug/receptacle combination.

As for this electrician, understanding code etc, I anxiously await the outcome here...

This electrician has checked twice to find nothing wrong while the OP/homeowner brings a FLIR camera

to research and illustrate problems...

Shawn

I made a mistake on the electric dryers.

I meant to say electric range or stove.

14-50 are also one of 2 very common receptacles at campgrounds

for the emergency charge... and for vendors at local festivals and events...

I am still curious about the choice of the 6-50 plug/receptacle combination.

As for this electrician, understanding code etc, I anxiously await the outcome here...

This electrician has checked twice to find nothing wrong while the OP/homeowner brings a FLIR camera

to research and illustrate problems...

Shawn

Oh, sorry, I thought that had been answered or explained above. Here's why:I am still curious about the choice of the 6-50 plug/receptacle combination.

The 6-XX outlet types are just 240V only. They have just the ground wire, and the Hot1, Hot2 that make the 240V circuit. Any kind of electric vehicle charging only needs a 240V connection. It doesn't need lower voltage.

The 14-XX series of outlet types are dual voltage. They can supply 240V and 120V. They have ground, Neutral, and Hot1, Hot2. They do this because some of those appliances, like the stove, have some smaller electronics parts like the light, timer, vent, etc. that are more common parts that are built to run from a 120V system. But then the really high power thing of the heating elements need the higher power of the 240V connection.

So, the 14-XX outlets have an extra neutral wire that is simply useless and not used in an electric car charging device. It is a pointless waste of money running that extra wire at your house that isn't going to be connected to anything anyway.

Granted, if someone really wanted to have a more general multi-purpose outlet at their garage and wanted to be able to plug in mobile homes from visiting relatives, then sure, you would want it to be a 14-50 outlet for that other purpose.

Hi all, thanks for your answers... Rocky already answered the "why did you use that plug" question, thanks Rocky. And the three feet of cable is actually THHN rated to 90 degrees C and rated to 55A so that wasn't the issue... but see below.

MXYMN, "positive" side was my layman way of saying the smaller prong... and up until yesterday, the outlet was used "occasionally" for my wife's kiln, (maybe once a month) she's a potter. The issue was not there initially, it developed and got worse over time... plugging and unplugging perhaps being the biggest culprit... or a loose connection... again see below.

What happened... I learned that I misspoke when I said my electrician had already checked it out. "my" favorite electrician installed the circuit originally for the kiln. The first time (almost a year ago) when I noticed the charging issue he came back and said everything was ok. When I called again, after many more problems to say I think there is something wrong, a different electrician from the company came to check it out when I was travelling. My wife told me "the electrician was here and he said everything is ok" and I assumed (I know...) that my favorite electrician showed up. I don't know what if anything this second guy did. This time I asked for and got my preferred electrician to show up... I showed him my FLIR photos where the plug had a hot spot of 135F, and the outlet, in the same position had a temp of 146F. The other side of the outlet was only about 112F. I hope that shows up in the attachment. .

First thing my electrician said is "you should have two outlets... the plug on the kiln uses a heavier-duty big brass prong than the TESLA adapter plug, so it is stretching out the connection spring inside the outlet and when you switch back and forth, you probably are not getting a good connection on the TESLA". He pointed out where he could see evidence of overheating on the outlet where the FLIR indicated the hot spot. Then he went through all the connections from the panel to the outlet and tightened everything up... although he said nothing needed to be tightened.

He then plugged the TESLA in and went onto another project. An hour later we went back to the car and it was still charging at 21 mph and the hot spot on the back of the plug was only 98F, in the same place it was 135F before. The cold side was 90 - 91F so there was still an imbalance (?) which might have been the burnt outlet. So the magic screwdriver did the trick, even though "nothing needed to be tightened..."

The final plan was a new outlet for the tesla, and run a separate line and for the kiln with it's own outlet, and no more unplugging / plugging in. Everything seems to be fine now... it wasn't a problem with the mobile connector, rather, as everyone said, something in the connecting circuit.

MXYMN, "positive" side was my layman way of saying the smaller prong... and up until yesterday, the outlet was used "occasionally" for my wife's kiln, (maybe once a month) she's a potter. The issue was not there initially, it developed and got worse over time... plugging and unplugging perhaps being the biggest culprit... or a loose connection... again see below.

What happened... I learned that I misspoke when I said my electrician had already checked it out. "my" favorite electrician installed the circuit originally for the kiln. The first time (almost a year ago) when I noticed the charging issue he came back and said everything was ok. When I called again, after many more problems to say I think there is something wrong, a different electrician from the company came to check it out when I was travelling. My wife told me "the electrician was here and he said everything is ok" and I assumed (I know...) that my favorite electrician showed up. I don't know what if anything this second guy did. This time I asked for and got my preferred electrician to show up... I showed him my FLIR photos where the plug had a hot spot of 135F, and the outlet, in the same position had a temp of 146F. The other side of the outlet was only about 112F. I hope that shows up in the attachment. .

First thing my electrician said is "you should have two outlets... the plug on the kiln uses a heavier-duty big brass prong than the TESLA adapter plug, so it is stretching out the connection spring inside the outlet and when you switch back and forth, you probably are not getting a good connection on the TESLA". He pointed out where he could see evidence of overheating on the outlet where the FLIR indicated the hot spot. Then he went through all the connections from the panel to the outlet and tightened everything up... although he said nothing needed to be tightened.

He then plugged the TESLA in and went onto another project. An hour later we went back to the car and it was still charging at 21 mph and the hot spot on the back of the plug was only 98F, in the same place it was 135F before. The cold side was 90 - 91F so there was still an imbalance (?) which might have been the burnt outlet. So the magic screwdriver did the trick, even though "nothing needed to be tightened..."

The final plan was a new outlet for the tesla, and run a separate line and for the kiln with it's own outlet, and no more unplugging / plugging in. Everything seems to be fine now... it wasn't a problem with the mobile connector, rather, as everyone said, something in the connecting circuit.

Attachments

mxnym

Active Member

This is a bit hokey. There are specifications for how tight everything should be, and in theory, a calibrated torque tool (screwdriver/wrench, depending on the torque required) should be used. While many electricians may often tighten these by feel without a tool, and I assume yours did the same. If I am correct, this would mean your electrician's hand is clearly out of calibration as evidenced by the tightening helping in spite of his comment to the contrary. I also find it concerning that he would tighten them while simultaneously saying they don't need it, because over-torquing can theoretically be bad, too. Regardless, the results speak for themselves. Something was loose, most likely a screw on the back of the outlet. Perhaps the electrician was using a torque tool to check/reset each connection and only meant that none of the others needed it but was checking them all when it appeared to you that he was tightening them?First thing my electrician said is "you should have two outlets... the plug on the kiln uses a heavier-duty big brass prong than the TESLA adapter plug, so it is stretching out the connection spring inside the outlet and when you switch back and forth, you probably are not getting a good connection on the TESLA". He pointed out where he could see evidence of overheating on the outlet where the FLIR indicated the hot spot. Then he went through all the connections from the panel to the outlet and tightened everything up... although he said nothing needed to be tightened.

<snip>

The final plan was a new outlet for the tesla, and run a separate line and for the kiln with it's own outlet, and no more unplugging / plugging in. Everything seems to be fine now... it wasn't a problem with the mobile connector, rather, as everyone said, something in the connecting circuit.

I thought he was using a regular screwdriver... and just put a little extra umph into each screw... as you said, the results speak for themselves. I've charged it three times since he was here and each time was problem free. Maybe to him nothing needed significant tightening, but just that little bit of extra on one of the screw connections did the trick... and it was probably the screw on the back of the outlet!This is a bit hokey. There are specifications for how tight everything should be, and in theory, a calibrated torque tool (screwdriver/wrench, depending on the torque required) should be used. While many electricians may often tighten these by feel without a tool, and I assume yours did the same. If I am correct, this would mean your electrician's hand is clearly out of calibration as evidenced by the tightening helping in spite of his comment to the contrary. I also find it concerning that he would tighten them while simultaneously saying they don't need it, because over-torquing can theoretically be bad, too. Regardless, the results speak for themselves. Something was loose, most likely a screw on the back of the outlet. Perhaps the electrician was using a torque tool to check/reset each connection and only meant that none of the others needed it but was checking them all when it appeared to you that he was tightening them?

Similar threads

- Replies

- 17

- Views

- 712

- Replies

- 3

- Views

- 331

- Replies

- 9

- Views

- 449

- Replies

- 6

- Views

- 355