There has recently been released a series of new research reports containing tests on Tesla Model 3 Cells (Panasonic 2170 NCA).

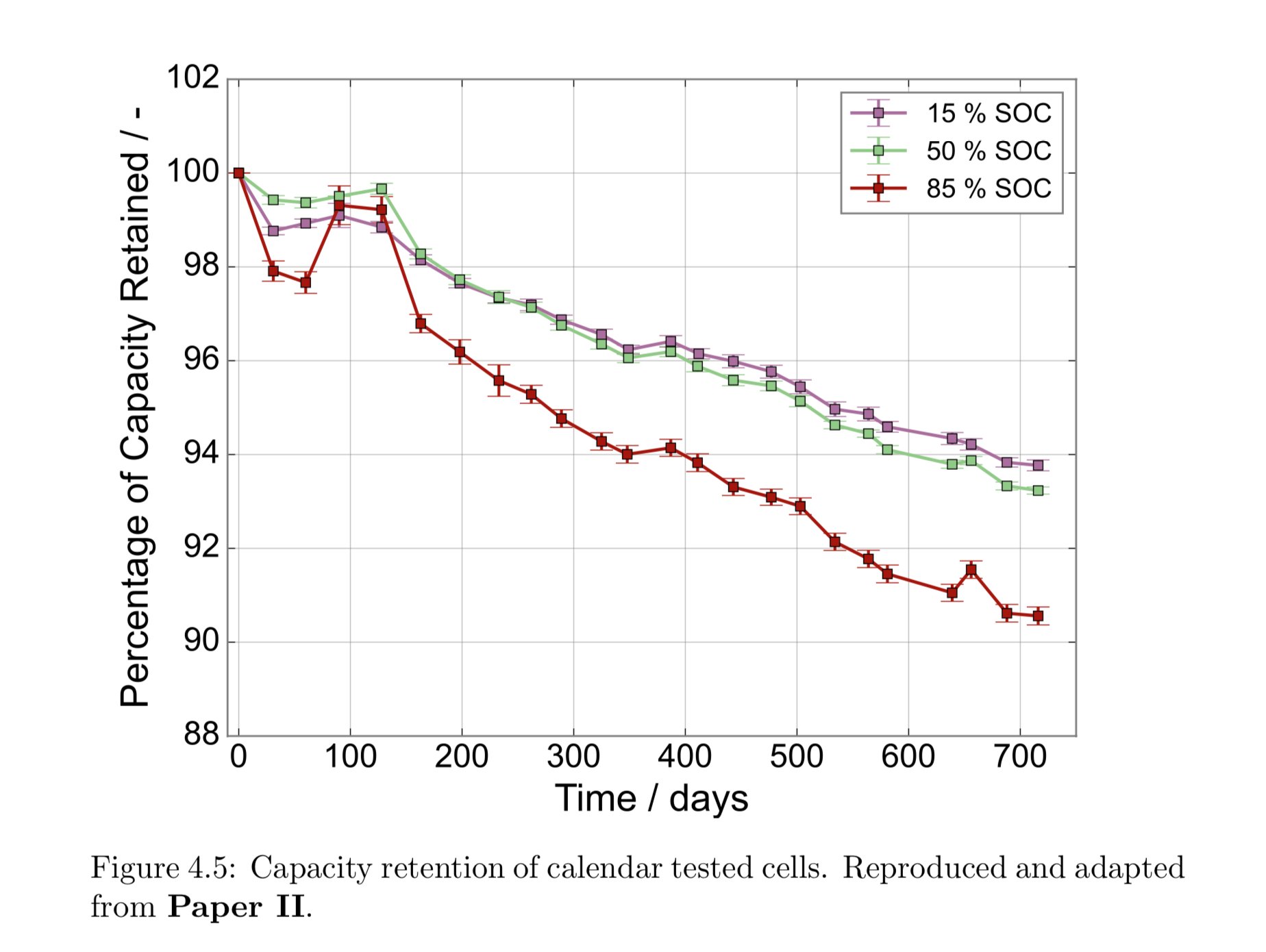

This is the calendar aging test from one of them (25C, 15, 50 and 85% SOC. Checkup once a month):

Using the datapoints from these and putting them in the old charts I ususally post, these match the olds ones quite good. As there is only three points, it do not show the real form of the curve, but all three points match the usual graphs.

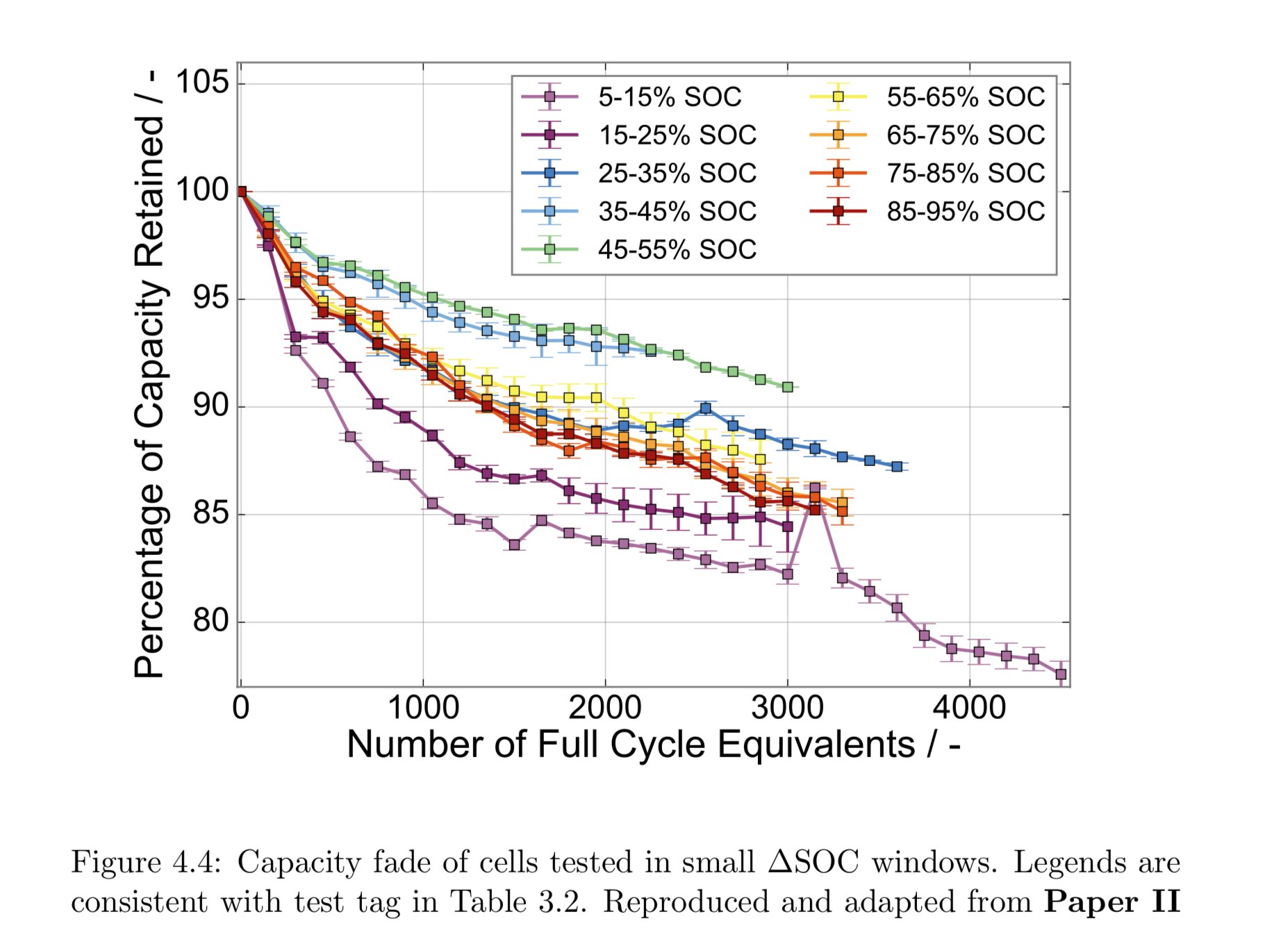

For the cyclic tests, they did use rather high currents, not really respresentative to normal EV use. (To the researchers defense, the currents used is sort of the most EV-battery manufacturers current in the specifications but still not close to the regulkar EV usage).

Charged with 0.33C which would match about a 25kW DC charger, or double to four times the usual rate EV owners use mostly. Probably not offsetting the result much, but to be clear this is how it was done.

Discharged with 1C, which would be 78kW, about enough to drive constant at 200kph. This is way above the average power used from a regular EV. Driving at higway speeds at 120kph/80mph or so, we normally use like 1/4 of that power.

The average car often has a average speed longterm of about 50-60kph, meaning we often use 1/8-1/4 of the power in these cyclic tests.

From other tests we can se that lower power reduce the wear, the degradation often reduces to somewhere down to 0.5-0.7C.

In this report the author was a bit surprised over the increased wear at 5-15% SOC and 15-25% SOC. I would say that it it a very high probability of that this is induced by the 1C discharge rate, and that our normal power rates used IRL would make this look different. This is nothing I can promise but from several other research tests we can see that there ususally is a tendency to slightly increase the cyclic degradation at the lowest SOC ranges.

According to this chart, the best cycling range is 55 % down to 35%( see note below about true SOC).

Note: These are “True SOC”. 0% in this chart is where the car already has stopped, and 5% in-chart is about 0% displayed and 55% in-chart is is about 57% displayed.

As I said above, there is a high probability that the low SOC range wear much less with a lower C-rate. Anyway, due to the high impact of calendar aging we most certainly benefit from staying low in SOC.

For the first two years, we would loose about 9-9.5% from calendar aging if staying at high SOC.

During these two years, if we drive 15-20K km annually (10-15Kmiles), and stay in the very low regime cycling (5-25% true SOC, thats 0-20% displayed SOC) we would loose about 1% from ~ 75-100 FCE cycles during these two years/30-40K km.

IRL its not possible to stay that low in SOC without actively stopping the charging, as 50% is the lowest setting (but for reference to low /high SOC).

To reach the same level of cyclic degradation from low SOC cycling according to the chart we would need about 700FCE, or about 280K km, but that is not really possible to do and at the same time stay at 5-25% SOC.

So, a car charged to 80-90%, and used as most EV’s is used, will mostly be above 55% SOC and have a calendar aging close to the 85% graph.

After two years, it will be around 10% degradation if the average cell temp is about 25C.

If the car was charged to 50-55% it would have a calendar aging around 6%, and the cyclic aging would be half the high SOC car, so more or less negligeble.

Link to one report

[Edit]For what its worth, if someone is worried about the low SOC below 20% (I am not, but I’m aware of the classic forum rumors), charging to 50-55% and charging for the daily drives at or above 20% (not talking longer traveling here) all aspect of this report if ticked-in-the-box.

I will not change any of my charging behavior because of this report. There is from time to time small differences in the reports and usually the reason for that can be found by thorougly comparing with other tests. We need much more than one report to state a “fact”.

This is the calendar aging test from one of them (25C, 15, 50 and 85% SOC. Checkup once a month):

Using the datapoints from these and putting them in the old charts I ususally post, these match the olds ones quite good. As there is only three points, it do not show the real form of the curve, but all three points match the usual graphs.

For the cyclic tests, they did use rather high currents, not really respresentative to normal EV use. (To the researchers defense, the currents used is sort of the most EV-battery manufacturers current in the specifications but still not close to the regulkar EV usage).

Charged with 0.33C which would match about a 25kW DC charger, or double to four times the usual rate EV owners use mostly. Probably not offsetting the result much, but to be clear this is how it was done.

Discharged with 1C, which would be 78kW, about enough to drive constant at 200kph. This is way above the average power used from a regular EV. Driving at higway speeds at 120kph/80mph or so, we normally use like 1/4 of that power.

The average car often has a average speed longterm of about 50-60kph, meaning we often use 1/8-1/4 of the power in these cyclic tests.

From other tests we can se that lower power reduce the wear, the degradation often reduces to somewhere down to 0.5-0.7C.

In this report the author was a bit surprised over the increased wear at 5-15% SOC and 15-25% SOC. I would say that it it a very high probability of that this is induced by the 1C discharge rate, and that our normal power rates used IRL would make this look different. This is nothing I can promise but from several other research tests we can see that there ususally is a tendency to slightly increase the cyclic degradation at the lowest SOC ranges.

According to this chart, the best cycling range is 55 % down to 35%( see note below about true SOC).

Note: These are “True SOC”. 0% in this chart is where the car already has stopped, and 5% in-chart is about 0% displayed and 55% in-chart is is about 57% displayed.

As I said above, there is a high probability that the low SOC range wear much less with a lower C-rate. Anyway, due to the high impact of calendar aging we most certainly benefit from staying low in SOC.

For the first two years, we would loose about 9-9.5% from calendar aging if staying at high SOC.

During these two years, if we drive 15-20K km annually (10-15Kmiles), and stay in the very low regime cycling (5-25% true SOC, thats 0-20% displayed SOC) we would loose about 1% from ~ 75-100 FCE cycles during these two years/30-40K km.

IRL its not possible to stay that low in SOC without actively stopping the charging, as 50% is the lowest setting (but for reference to low /high SOC).

To reach the same level of cyclic degradation from low SOC cycling according to the chart we would need about 700FCE, or about 280K km, but that is not really possible to do and at the same time stay at 5-25% SOC.

So, a car charged to 80-90%, and used as most EV’s is used, will mostly be above 55% SOC and have a calendar aging close to the 85% graph.

After two years, it will be around 10% degradation if the average cell temp is about 25C.

If the car was charged to 50-55% it would have a calendar aging around 6%, and the cyclic aging would be half the high SOC car, so more or less negligeble.

Link to one report

[Edit]For what its worth, if someone is worried about the low SOC below 20% (I am not, but I’m aware of the classic forum rumors), charging to 50-55% and charging for the daily drives at or above 20% (not talking longer traveling here) all aspect of this report if ticked-in-the-box.

I will not change any of my charging behavior because of this report. There is from time to time small differences in the reports and usually the reason for that can be found by thorougly comparing with other tests. We need much more than one report to state a “fact”.

Last edited: