Artful Dodger

"Neko no me"

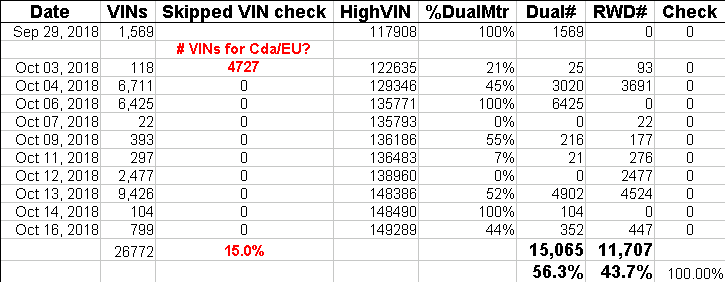

Here are the stats and analysis I promised in my Comment #49890 above for Model 3 Dual Motor/RWD VIN production split:

Stats with Inferences:

Stats with Inferences:

- approx. 26,770 Model 3s are currently planned for production

- AWD is about 56.3% of planned production

- RWD is about 43.7% of planned production

- this proportion will likely change due to intro of L3MR (see below)

- there is likely about 2-weeks leadtime in prod. planning vs. VINs

- let's assume planned VINs above are for 31 days (October) - W.A.G.

- current production plans imply about 6,045 Model 3s per week

- that implies Panasonic's current production is 6K LR packs/wk worth of cells

- wag. if L3MR uses 25% fewer cells vs LR, then prod. multiple is 1.33x cars/cells

- assuming AWD production remains the same, Nov production becomes:

- 3,400 AWD per week

- 3,525 L3MR per week

- 6,925 Model 3s per week

- assuming a 50/50 L3MR/T3LR bty cell split, then Nov prod. becomes:

- 3,020 AWD per week

- 4,030 L3MR per week

- 7,050 Model 3s per week

- Note: to get to 8,000 Model 3s per week under current battery cell constraints, about 97% of production would have to be L3MR.

Last edited: