Hi all, I'm looking for some insight on whether my panels are currently wired optimally for my situation. I don't have a background as an electrician or anything, so apologies in advance if I make any incorrect assumptions.

I had my 18-panel (340W Qcells) system installed in September 2021. My install includes 8 panels on my main roof (4 south-facing, 4 east-facing) and 10 panels on my detached garage (5 south-facing, 5 north-facing). For about 4-5 months of the year (late fall through early spring) I have some shading on some or all of my south-facing garage panels from 10am-12pm. No shading on any of the other 13 panels. So I asked for the installers to keep that in mind when they set up strings. Recently, I had a DC arc fault 36 error show up on my inverter, and my service tech rewired the inverter and changed the strings from 2 strings wired in parallel (jumpers on Strings 1 and 2) to 2 strings wired in series (no jumpers).

I want to know if there are any drawbacks to the current wiring set-up, and if I need to push a fix so the two sets of panels can each be wired in parallel again. I tried to include relevant info, but let me know if there's any other info that would help. Any insight is much appreciated, as I don't want to leave an issue unaddressed, but I also don't want to bother the technician if the current wiring fits my needs.

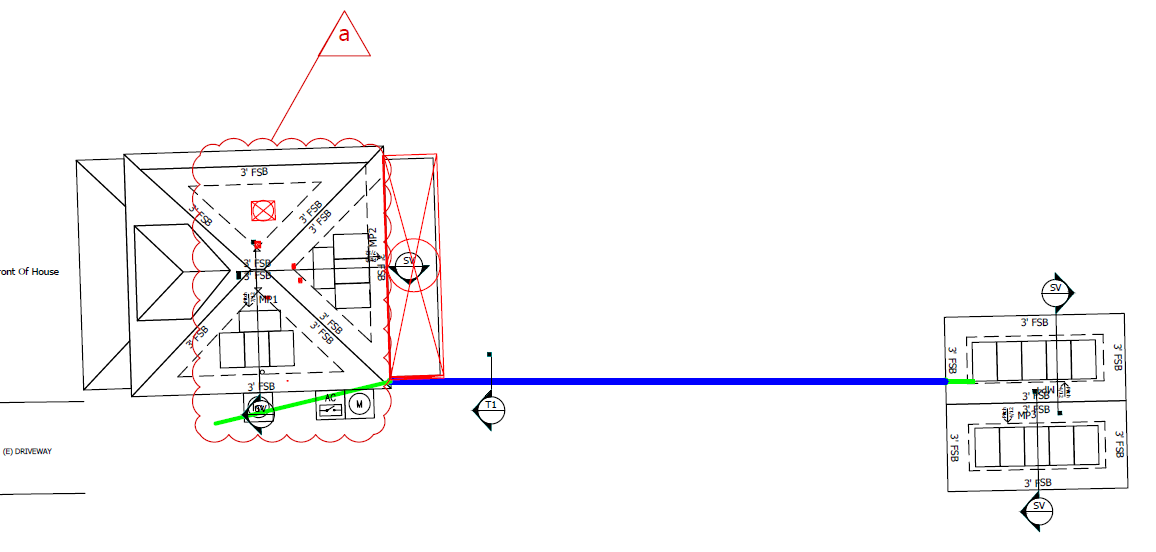

Layout on roofs. Bottom of image is South, so 4 panels on main roof are S, 4 panels are E. 5 panels on garage roof are S and 5 are N. Partial shading on garage S roof from 10am-12pm).

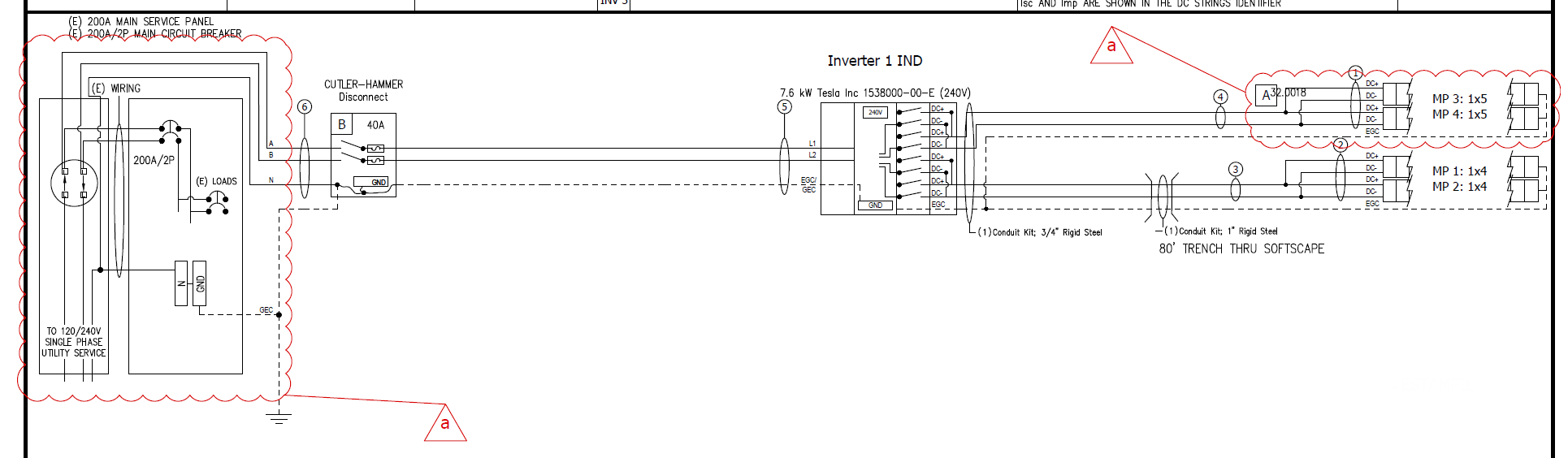

Wiring plan:

Initial inverter wiring when installed (parallel wiring on Strings 1 and 2):

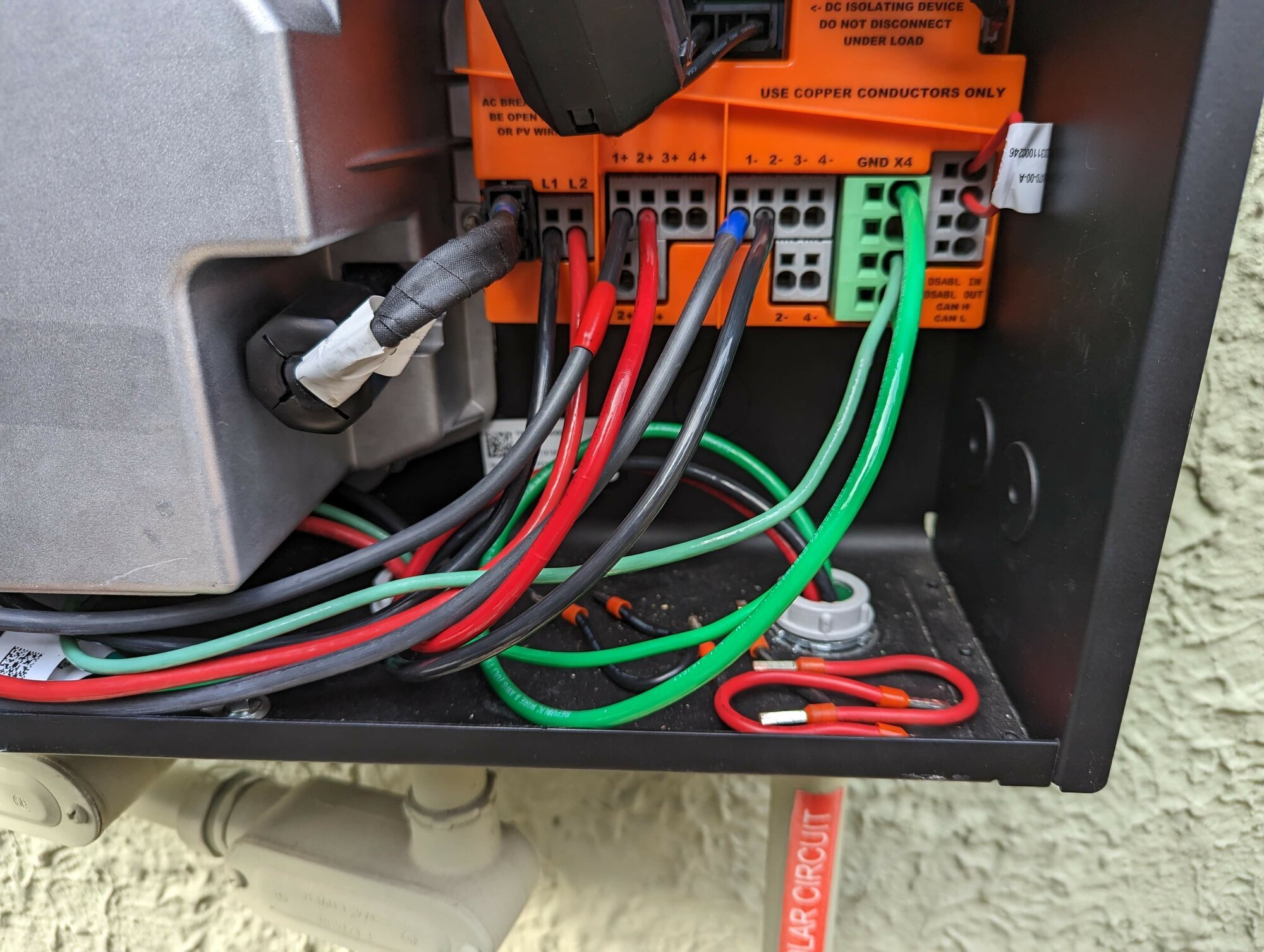

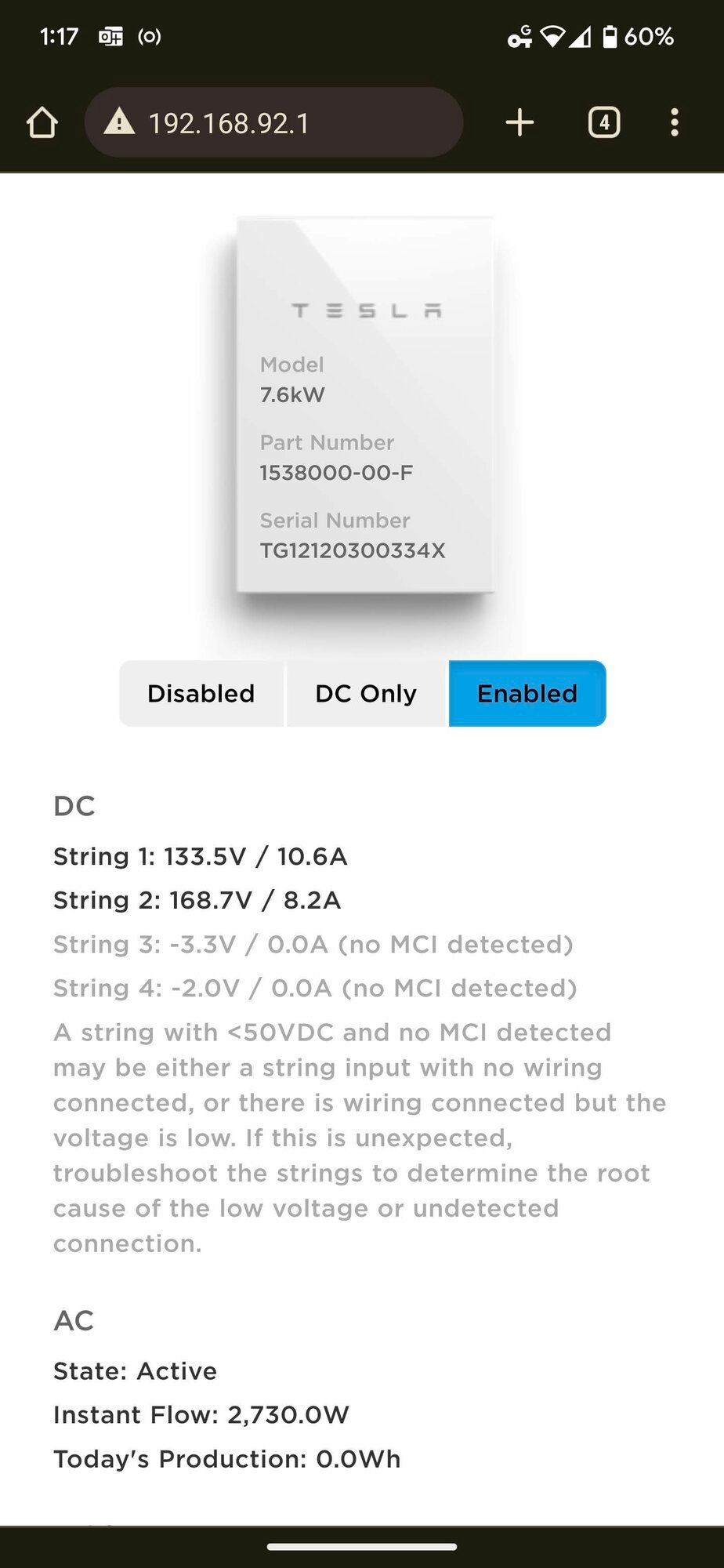

Inverter wiring after tech visit due to DC arc fault 36 (series wiring on Strings 1 and 2):

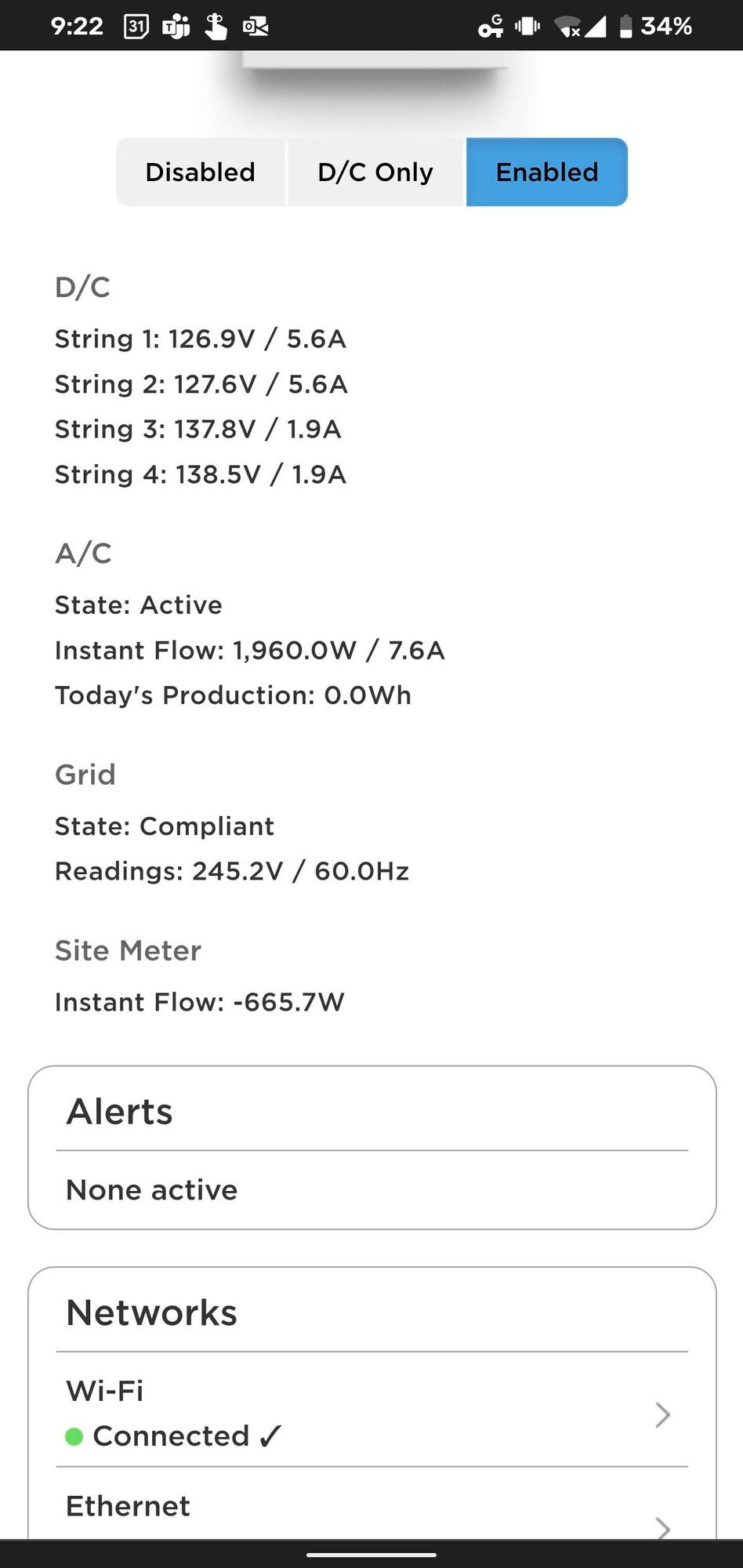

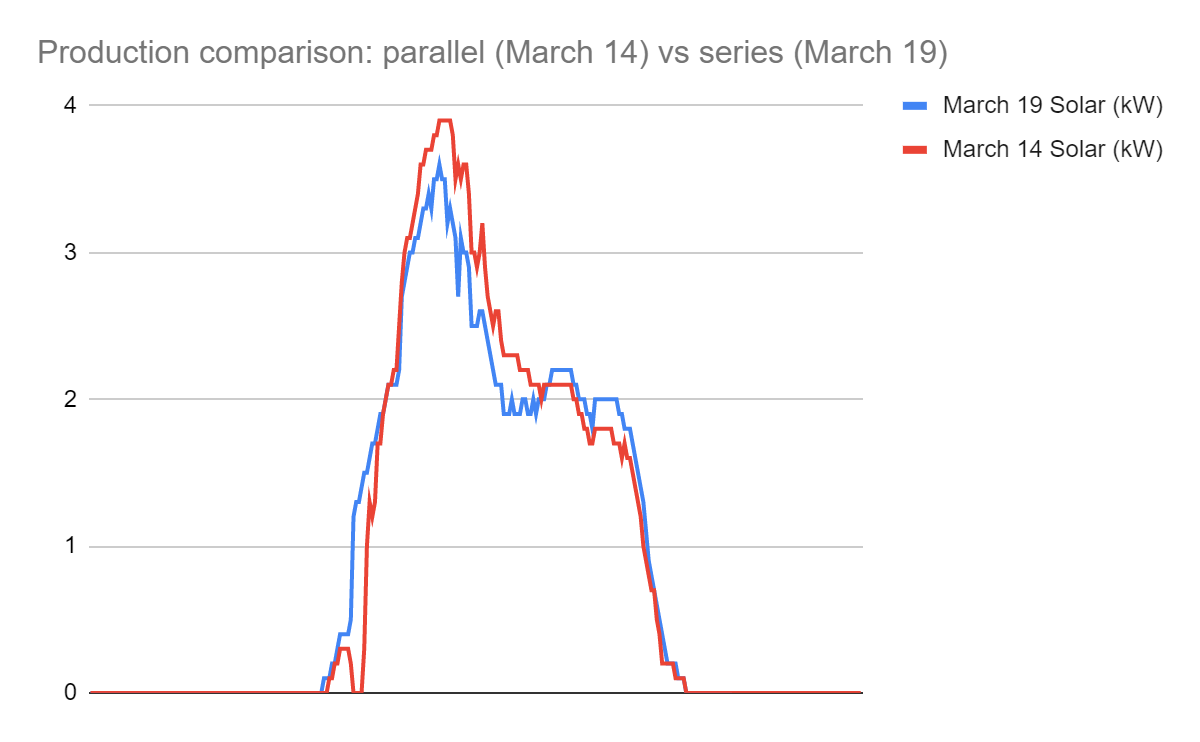

Production on cloudless days (similar temperatures): prior to arc fault (parallel wiring) vs after repair/rewiring (series wiring):

I had my 18-panel (340W Qcells) system installed in September 2021. My install includes 8 panels on my main roof (4 south-facing, 4 east-facing) and 10 panels on my detached garage (5 south-facing, 5 north-facing). For about 4-5 months of the year (late fall through early spring) I have some shading on some or all of my south-facing garage panels from 10am-12pm. No shading on any of the other 13 panels. So I asked for the installers to keep that in mind when they set up strings. Recently, I had a DC arc fault 36 error show up on my inverter, and my service tech rewired the inverter and changed the strings from 2 strings wired in parallel (jumpers on Strings 1 and 2) to 2 strings wired in series (no jumpers).

I want to know if there are any drawbacks to the current wiring set-up, and if I need to push a fix so the two sets of panels can each be wired in parallel again. I tried to include relevant info, but let me know if there's any other info that would help. Any insight is much appreciated, as I don't want to leave an issue unaddressed, but I also don't want to bother the technician if the current wiring fits my needs.

Layout on roofs. Bottom of image is South, so 4 panels on main roof are S, 4 panels are E. 5 panels on garage roof are S and 5 are N. Partial shading on garage S roof from 10am-12pm).

Wiring plan:

Initial inverter wiring when installed (parallel wiring on Strings 1 and 2):

Inverter wiring after tech visit due to DC arc fault 36 (series wiring on Strings 1 and 2):

Production on cloudless days (similar temperatures): prior to arc fault (parallel wiring) vs after repair/rewiring (series wiring):