I hereby relinquish to Tesla Motors, Inc.or now to the end of eternity, for me, my heirs and assigns, all rights and claims of any kind whatsoever to "Tesla Pizzazz". This relinquishment specifically does not apply to any entity other than Tesla Motors, Inc. or its assigns.Has a lot more cache than 'model 3'........I think you are on to something.

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla Gigafactory Investor Thread

- Thread starter teddyg

- Start date

-

- Tags

- Gigafactory TSLA

To boot, it is a reprint of an article out over a month ago I believe.

Indeed, there is an editor's note at the top stating that the article was originally published on June 21. The article reappeared shortly after today's current high. There is no allowance for comments to today's posting of he article. Why does TheStreet feel it needs to perform the service of regurgitating old FUD? Why won't it allow rebuttals to the article?

Indeed, there is an editor's note at the top stating that the article was originally published on June 21. The article reappeared shortly after today's current high. There is no allowance for comments to today's posting of he article. Why does TheStreet feel it needs to perform the service of regurgitating old FUD? Why won't it allow rebuttals to the article?

Curt.....We are debating whether the ER dates for TM and Panasonic being the same is coincidence or by design.....your thoughts? Thanks

Curt.....We are debating whether the ER dates for TM and Panasonic being the same is coincidence or by design.....your thoughts? Thanks

Coincidence, of course, is quite possible. However if there were to be a major announcement involving both companies, then scheduling nearly simultaneous earnings reports would seem rather appropriate.

Coincidence, of course, is quite possible. However if there were to be a major announcement involving both companies, then scheduling nearly simultaneous earnings reports would seem rather appropriate.

I think given the different market hours, this wouldn't be the best way to do a major announcement. Panasonic's earnings would come out in the morning (a full trading day) before Tesla. Tesla's earnings call would be early in the morning and brush up right against the open of the Japanese market, not ideal for letting the market digest a material announcement.

A joint press release is a much more appropriate mechanism for a big TM/Panasonic announcement. I think earnings are most likely on the same calendar day by coincidence. (Who knows though, they may press release a day ahead then both talk about it during earnings)

...(Who knows though, they may press release a day ahead then both talk about it during earnings)

Indeed, if there were to be a major joint announcement, that would be the sensible way to handle it.

Muskol

Member

Causalien

Prime 8 ball Oracle

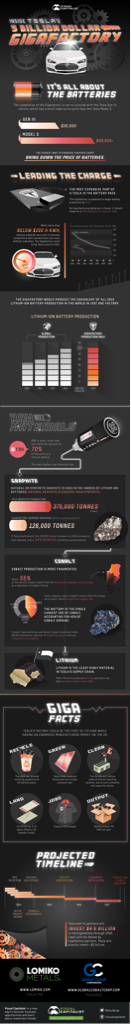

Interesting implication in Cobalt and Graphite miningNeat info graphic: Inside Teslas $5 Billion Gigafactory | Visual Capitalist

chickensevil

Active Member

As long as they can get the graphite in a minimal polluting process, I can see them shifting away from synthetic. And while most combat comes from the Congo, aren't there other, closer options? And finally no mention of Nickel?

As long as they can get the graphite in a minimal polluting process, I can see them shifting away from synthetic. And while most combat comes from the Congo, aren't there other, closer options? And finally no mention of Nickel?

FWIW, Elon recently said that the synthetic graphite they currently use is better than natural as it results in a more reliable battery.

Causalien

Prime 8 ball Oracle

So, for the chemists out there. If battery chemistry changes in the future, will synthetic graphite still be part of the mixture? Or is the usage of graphite right now just a one shot thing specifically for this chemistry?FWIW, Elon recently said that the synthetic graphite they currently use is better than natural as it results in a more reliable battery.

chickensevil

Active Member

So, for the chemists out there. If battery chemistry changes in the future, will synthetic graphite still be part of the mixture? Or is the usage of graphite right now just a one shot thing specifically for this chemistry?

Not a chemist, but my basic understanding is that Carbon is needed as part of the reaction. I would guess that you could use some other kind of carbon bond for it, but I assume there is good reason that graphite is the carbon of choice.

- - - Updated - - -

FWIW, Elon recently said that the synthetic graphite they currently use is better than natural as it results in a more reliable battery.

Makes sense. I was just thinking about it from a cost stance since I believe synthetic graphite is about 2x the price. But synthetic would ensure no impurities in the chemical.

Zzzz...

Member

So, for the chemists out there. If battery chemistry changes in the future, will synthetic graphite still be part of the mixture? Or is the usage of graphite right now just a one shot thing specifically for this chemistry?

Graphite is used by 95+% of all li-ion cells currently in production. Virtually all chemistries used in Leafs, Volts, Sparks, Teslas and tablets/smartphones have very similar anode formulations, essentially a graphite.

But going forward it probably would not be the case. First smartphones with silicon based anode entered production this year. Silicon is an emerging and very promising tech that potentially could provide more kWh per kg. But currently it got it share of problems, biggest of which is fast degradation as cell cycles.

Another very promising tech is lithium sulfur cells. They also are entering limited commercialization. Again, no place for graphite. Samer promise - more energy per mass plus they potentially could be produced much cheaper. And very similar bag of problems... Interestingly Elon was asked about Li-S chemistry(last shareholder meeting IIRC), his reply was along the lines of low volumetric density of lithium sulfur cells. IMO it is not the biggest problem of Li-S as a tech, may be problem of specific cells that hit Tesla testing lab. But!

There are a good reasons as to why silicon based anodes and Li-S are not in mass production yet. But I hope situation will change in next three to four years from now. With Li-S starting to replace conventional li-ion at least in high end applications like in smartphones.

- - - Updated - - -

Well I'm not a chemist, but I'm reading li-ion related peer reviewed papers for fun of it, from time to time, and some of those papers are not even covered by popsci medias

chickensevil

Active Member

Well I'm not a chemist, but I'm reading li-ion related peer reviewed papers for fun of it, from time to time, and some of those papers are not even covered by popsci medias

See that's pretty much the same boat I find myself in with regards to this. I would love to read over some of the various articles and journals you might have come across on the subject, and certainly the better ones you have found.

In either case, as long as batteries continue to be able to be made in a round cylindrical shape, I am not worried about whatever Tesla seems to put in the car. I am sure it is the best battery for their purposes. Keep in mind that their two critical things that they care most about is cell life and energy density. Most everything else seems to be secondary to their cause.

Graphite is used by 95+% of all li-ion cells currently in production. Virtually all chemistries used in Leafs, Volts, Sparks, Teslas and tablets/smartphones have very similar anode formulations, essentially a graphite.

But going forward it probably would not be the case. First smartphones with silicon based anode entered production this year. Silicon is an emerging and very promising tech that potentially could provide more kWh per kg. But currently it got it share of problems, biggest of which is fast degradation as cell cycles.

Didn't they fix this issue by using Sand?

Zzzz...

Member

I would love to read over some of the various articles and journals you might have come across on the subject, and certainly the better ones you have found.

Mine favorite paper so far: http://homepages.rpi.edu/~koratn/resources/publications/ncomm2.pdf

1) Only carbon for anode and cathode, plus lithium for cathode of course. No nickel, no cobalt, no aluminum.

2) No need for current collectors, so no aluminium and copper there.

3) Extremely stable electrodes, no degradation. Provided stable enough electrolyte 20+ years without degradation seems possible. Well more testing needed but this is what I see.

4) Fully compatible with all widely used commercially available electrolyte systems and separators.

5) Should have no temperature related degradations(we are speaking about electrodes again).

6) High enough coulombic efficiency, so no usual crap that potentially cripple other "breakthrough" batteries. And I do not see why proposed cells will get problems with self discharge.

7) No extreme or semi-extreme temperatures required to operate(like >70[SUP]0[/SUP]C requirement to operate efficiently, no such crap).

8) Seems it is possible to fully discharge cell without bricking it(they cycled cells down to 0.03V...)

9) Potentially electrodes are capable of 150C(recharge in 24 sec anyone?). High C rates confirme low or no degradation. But who needs more than 10C anyway?

10) Last but not least, I would estimate around ~340Wh/Kg specific energy on a cell level(please do not pay too much attention to Wh/Kg numbers in the paper). Not a record, but coupled with above points make this chemistry very interesting for EV applications, especially if you take into account possibility that thermal management would not be needed for the battery pack(stable electrodes).

Interestingly, just one month AFTER this paper got published news media started to cry out about "revolutionary" carbon-carbon battery from some Japanese startup. Which coincidentally decided to came out of stealth mode right after above paper saw light of the day. While providing virtually no data about performance of their carbon-carbon cells...

And sure there were other interesting papers.

Price is also a crucial one.they care most about is cell life and energy density. Most everything else seems to be secondary to their cause.

- - - Updated - - -

There many dozens of startups that develop silicon anode tech. Some of them in stealth mode. Many hundreds papers are published by academy. The big players are also developing. Last year big japanese firm announced commercial availability of silicon based anode material. But such development is a very complicated process. Usually there are catches/fine prints/tradeoffs. Price vs performance vs longevity vs gravimetric density vs power density vs temperature envelope etc. One could optimize for some parameters at expense of others. There is no easy fixes that improve everything. Here is "the real" thing, something that consumers could actually buy: At long last, new lithium battery tech actually arrives on the market (and might already be in your smartphone) | ExtremeTechDidn't they fix this issue by using Sand?

Last edited:

chickensevil

Active Member

My understanding of the carbon/carbon cells is that they are not dense enough which would hurt the range of the Tesla. And sure you could potentially fit more cells in one space but that just means more overall weight on the vehicle. And how much of a theoretical cost savings are we talking about here. Because unless it is enough that you could add another 1000 or so cells to the car and come under the current cost of the battery then my understanding is that it wouldnt pan out.

I sawa energy density graph on these cells and it didn't look so great when compared to other cells. The rest of it does seem interesting, and I am not saying that they shouldnt research it further, but as of right now, I don't see it being the fix that Tesla is primarily interested in which is density.

In fairness I haven't read the linked paper, and I will do so tomorrow sometime, so maybe I will be singing a different tune at that point. It is interesting tech and I do love the rest of the properties it has. It is true that there doesn't seem to be that magic bullet of a battery where you get everything you could want in a cell... There is always a trade off it seems

I sawa energy density graph on these cells and it didn't look so great when compared to other cells. The rest of it does seem interesting, and I am not saying that they shouldnt research it further, but as of right now, I don't see it being the fix that Tesla is primarily interested in which is density.

In fairness I haven't read the linked paper, and I will do so tomorrow sometime, so maybe I will be singing a different tune at that point. It is interesting tech and I do love the rest of the properties it has. It is true that there doesn't seem to be that magic bullet of a battery where you get everything you could want in a cell... There is always a trade off it seems

Mitthrawnuruodo

Member

More details on the Sparks\Reno site Guest Post: Top-Secret Groundworks Outside Reno, NV Mark First Tesla Gigafactory Site

Anybody watching this stock ticker react to every news article referencing gigafactory Reno?

WESTERN LITHIUM USA: OTCMKTS:WLCDF quotes & news - Google Finance

Similar threads

- Replies

- 1

- Views

- 770

- Replies

- 0

- Views

- 201

- Replies

- 3

- Views

- 519

- Replies

- 1

- Views

- 510