Checks out:Indeed, and let's not forget the straight-out criminal practice of marking short sales as long. It's an offense which takes the $EC 7 yrs to prosecute (if ever), and then the token fines they issue are no deterent whatsoever:

Illegal Naked Short Selling Appears to Lie at the Heart of an Extensive Stock Manipulation Scheme | Smith on Stocks (Oct 15, 2023)HSBC, BNP Paribas may face criminal charges over short selling | Korea Joon Gang Daily (Oct 18, 2023)

Hmm, HSBC again...

Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla, TSLA & the Investment World: the Perpetual Investors' Roundtable

- Thread starter AudubonB

- Start date

UkNorthampton

TSLA - 12+ startups in 1

$900 per gigacasting (Model Y rear, cost for repair centres pre-taxes)

www.autocar.co.uk

www.autocar.co.uk

Paywalled - but I found some info on a Turkish X post, this could be unreliable reporting, but another source below.

[Google translate]

Another report - Model Y insurance costs may be lowered as Tesla addresses gigacast part deformation concerns and repair prices

Megacast pioneer Tesla moves to calm insurer fears | Autocar

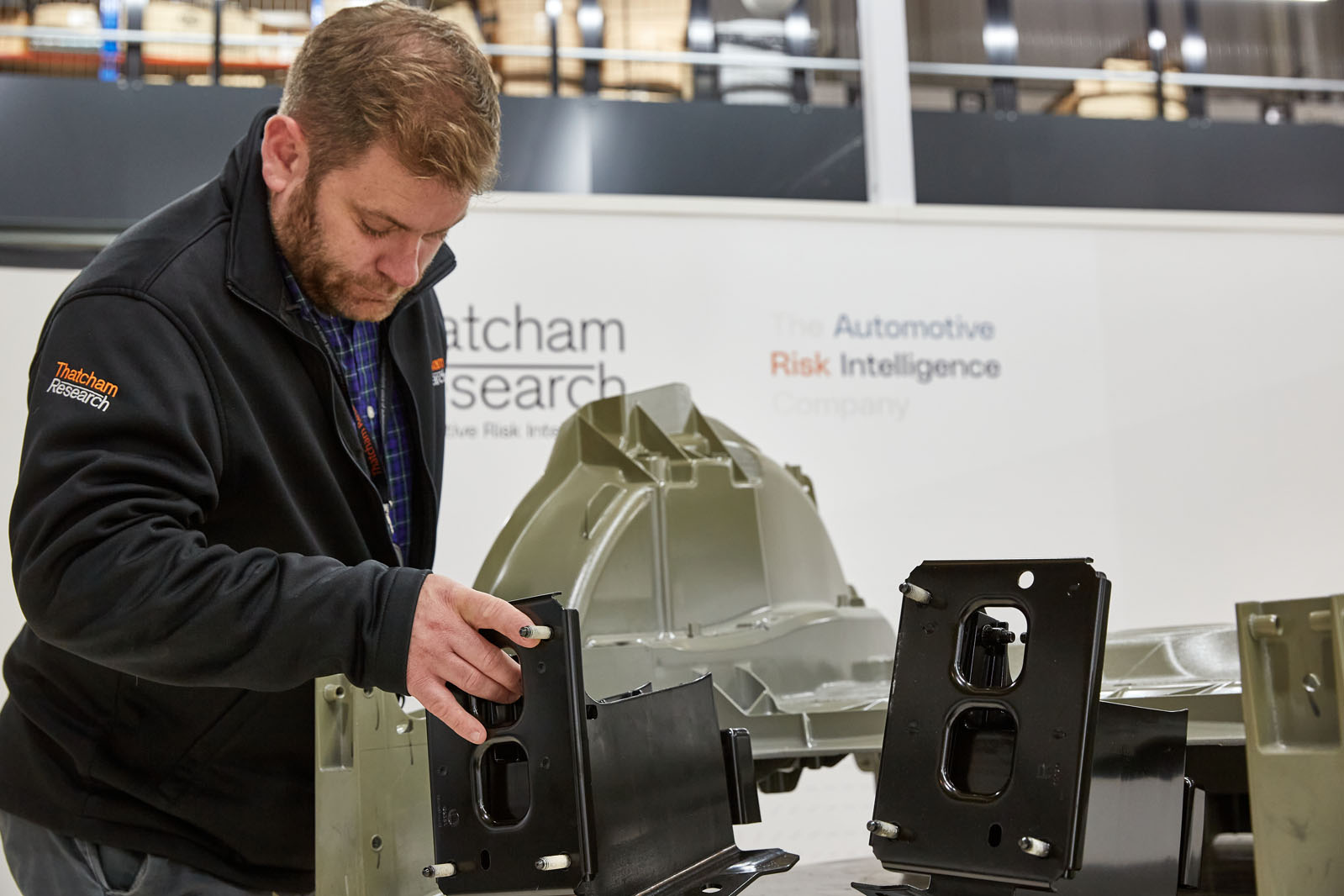

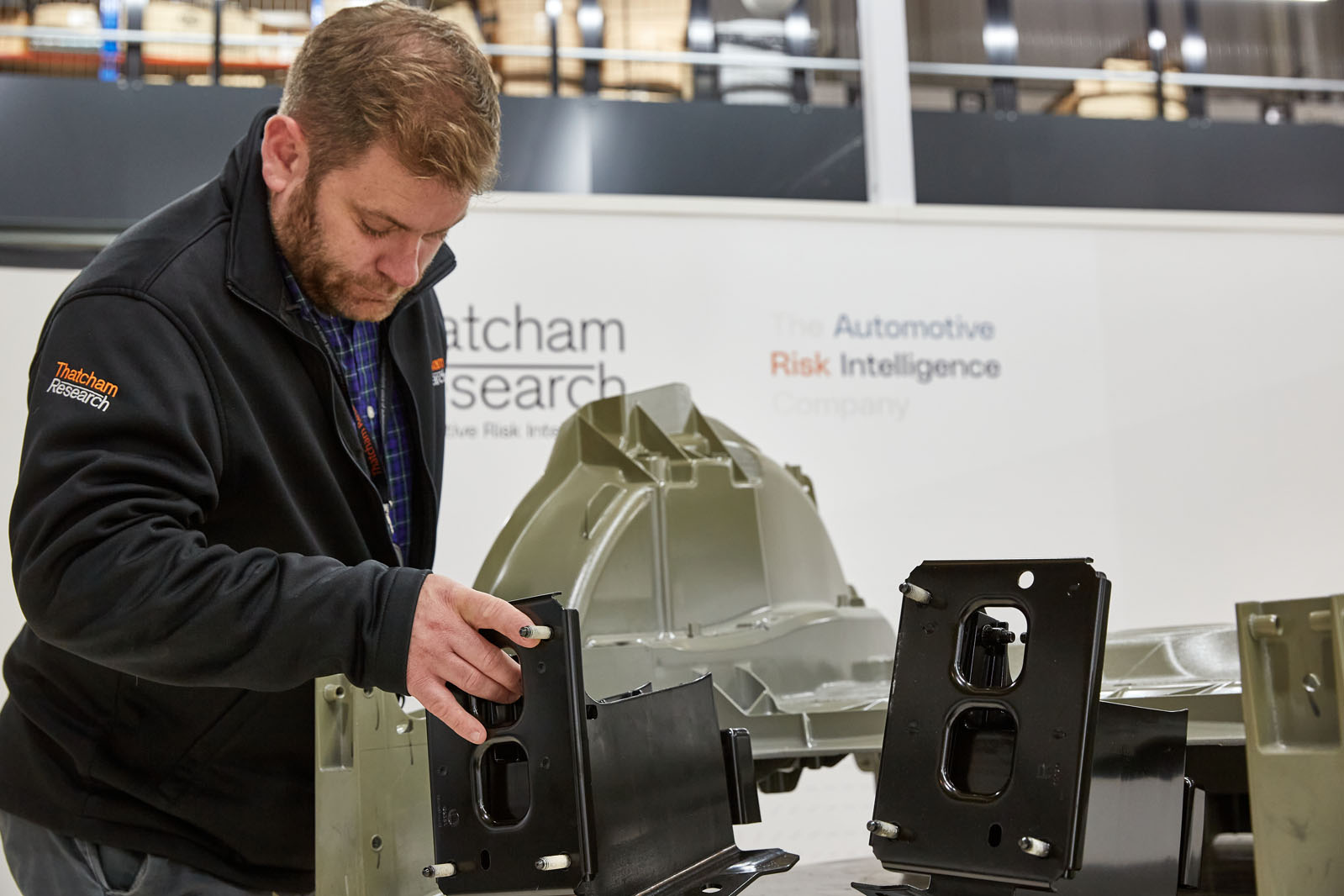

Thatcham Research tasked with testing EV maker's new underbody after concerns raised over repair costs

Megacast pioneer Tesla moves to calm insurer fears

Thatcham Research tasked with testing EV maker's new underbody after concerns raised over repair costs

Paywalled - but I found some info on a Turkish X post, this could be unreliable reporting, but another source below.

[Google translate]

How will cars with a single-piece chassis be repaired?

The one-piece chassis design pioneered by#Tesla ; While it allows the production of lighter, more durable, cheaper and faster vehicles, it raises questions about repairability.

According to the latest research published in the UK, Tesla has taken serious measures regarding the repairability of the rear chassis in light and medium-sized damage. In case of a complete chassis replacement, it is possible to obtain a new giant chassis from Tesla by paying a small fee of ~$900 + VAT. (Thatcham Research)

The one-piece chassis produced using3 series aluminum can be welded in case of breaks of a certain size after an accident, and the resulting break does not prevent the vehicle from getting back on the road safely. However, the real problem in major accidents is the damage to the battery pack.

Damage to the battery pack in the event of an accident increases the risk of explosion and fire and also accelerates the loss of capacity of the battery. In this regard, it is very important that the one-piece chassis has high strength and that it bends and breaks in major accidents instead of crushing the battery pack, in order to protect the battery, which constitutes the largest part of the vehicle cost.

According to the forecast shared by S&P Global Mobility, the use of single-piece chassis instead of old-school chassis in the automobile market will reach 15-20% by 2030.

Another report - Model Y insurance costs may be lowered as Tesla addresses gigacast part deformation concerns and repair prices

Now, however, it is becoming apparent that Tesla is not only trying to address deformation concerns, but it has also created a thorough repair manual for service centers and, if all else fails, it is supplying the problematic Model Y body section seemingly at cost. According to Thatcham, the gigacast aluminum rear section of the Model Y is itemized by repair centers for only £752.50.

That price is "really not a lot when you look at how much material is in it," adds Bright. Eventually, these positive gigacast parts repairability and replacement cost observations by the auto insurers' research shop could lead to lower premiums for all Tesla owners.

Skryll

Active Member

And, does this speed up or slow down Tesla owned supercharger buildout.3a. To what extent (and how) will these Tesla-produced, 3rd-party-branded Superchargers be integrated into the navigation and trip planning in Tesla cars?

Don't want another EV1 strangle

cliff harris

Member

If those gigacast prices are accurate, then thats insane!

Q4 margins might be good . Cybertruck pricing may end up being way more competitive than we thought, at least eventually. It would be mad for Tesla not to capitalize in demand outstripping supply for at least the first year...

. Cybertruck pricing may end up being way more competitive than we thought, at least eventually. It would be mad for Tesla not to capitalize in demand outstripping supply for at least the first year...

This also bodes incredibly well for next gen vehicle. In a sane world, if that price is confirmed anywhere, the stock should go nuts. Np wonder the company is all-in on gigacasting.

Q4 margins might be good

This also bodes incredibly well for next gen vehicle. In a sane world, if that price is confirmed anywhere, the stock should go nuts. Np wonder the company is all-in on gigacasting.

This does sound good, but I always thought the cost of the basic chassis in steel or aluminum when first created was fairly cheap. Anyone that can give a ballpark figure what VW is paying for the similar pieces on the ID4 as the parts that are gigacast on the Model Y. I might not grasp the big difference here. I would think VW pays maybe double so $1800 for the same parts but that is still only $900 more that can't be that important in the whole car picture can it?If those gigacast prices are accurate, then thats insane!

Q4 margins might be good. Cybertruck pricing may end up being way more competitive than we thought, at least eventually. It would be mad for Tesla not to capitalize in demand outstripping supply for at least the first year...

This also bodes incredibly well for next gen vehicle. In a sane world, if that price is confirmed anywhere, the stock should go nuts. Np wonder the company is all-in on gigacasting.

It’s more about the Volume of parts and labor/time in the conventional frameThis does sound good, but I always thought the cost of the basic chassis in steel or aluminum when first created was fairly cheap. Anyone that can give a ballpark figure what VW is paying for the similar pieces on the ID4 as the parts that are gigacast on the Model Y. I might not grasp the big difference here. I would think VW pays maybe double so $1800 for the same parts but that is still only $900 more that can't be that important in the whole car picture can it?

Hey-Hey there... we might have to pay for those first few units. At low volume, I doubt any price would make a dent. OTOH, healthy margins would be nice to report.It would be mad for Tesla not to capitalize in demand outstripping supply for at least the first year..

I still say keep it in line with the target price, (conceal initial low or neg margins by clustering the data overall), and create a FRENZY with initial CT demand! Breakout the CT margins next year sometime.

Stellantis offering buyouts to about half its US salaried employees

(Reuters) -Chrysler-parent Stellantis said Monday it is offering 6,400 U.S. salaried employees voluntary buyouts as it works to cut costs amid the transition to electric vehicles and agreeing to a new United Auto Workers contract. The buyouts would be about half the company's salaried U.S...

1/2 the salaried workforce, I feel bad for them.

Well it's "about two weeks" away...Surprised TSLA kept going (past 200 day, and past Max Pain). Isn't it too early for FOMO on Nov 30th.

tmoz

S85D, Y LR, ex Prius PiP

2nd Update. Another white Model Y LR has arrived in Scottsdale. We will hopefully take delivery on Thursday.Update. Almost took delivery on 11/7, but the hood was warped, leaving a bit of a bump at the front seal with the bumper. Plus some bubbles in the paint near the headlight. Would have been in the shop for 2 to 5 weeks. The bump in the hood worried me as to being bad at higher speeds on the highway. There is another vehicle in transit. So hopefully next week. Crossing my fingers on the next one not having issues. Other than that, the rest of the car was fine.

But I have the tax info. Registration fees were about $906, and sales tax $4100.

Hoping for a good experience on Thursday - will give a final update.

We are transferring free lifetime supercharging from the 2015 S to the LR Y

cliff harris

Member

Thats only one casting, so if you save double that on a single car for front and rear, thats $1,800 saved. Not much for the manufacturing cost total of a plaid model S, but for a next gen model 2, thats a BIG saving.This does sound good, but I always thought the cost of the basic chassis in steel or aluminum when first created was fairly cheap. Anyone that can give a ballpark figure what VW is paying for the similar pieces on the ID4 as the parts that are gigacast on the Model Y. I might not grasp the big difference here. I would think VW pays maybe double so $1800 for the same parts but that is still only $900 more that can't be that important in the whole car picture can it?

Plus castings mean way better alignment, as no inaccuracies to build up with separate components. Much faster build time, much smaller factory footprint and presumably less end-line QA due to the better alignment?

I think if gigacastings saved *nothing* but factory space, it would likely still make sense. For it to improve build quality and reduce production cost and time is just a bonus.

I really think shareholders are yet to see the real impact of gigacasting, or 4680s on the balance sheet. This stuff seems to take ages to filter through, but its clear the final plan is everything made in single casting, structural 4680 battery. Once that vision is realized its going to be very clear in margins.

AFAIK we don't yet even have one vehicle yet that is front+rear+structural+4680? I get the impression *some* model Ys are rear casting plus 4680s, but nowhere has the full setup yet?

The 4680 Model Y's that Giga Texas was producing until recently had front and rear castings plus structural battery pack.AFAIK we don't yet even have one vehicle yet that is front+rear+structural+4680? I get the impression *some* model Ys are rear casting plus 4680s, but nowhere has the full setup yet?

Not sure about the Berlin BYD blade Model Y's but these could also use both castings as Berlin has produced both.

Same. Will test next Tuesday. Received a test drive invitation last week, almost all slot were still free yesterday.I´ll have a Highland test drive Thursday. If there is anything I should look for or any questions I should ask, PM me! I own a 2019 M3 for comparison.

cliff harris

Member

Interesting. I suspect thats still a relatively small number of all model Ys made at the moment though. When shanghai/texas/berlin/fremont are all making 3's and Y's this way, the impact should be significant.The 4680 Model Y's that Giga Texas was producing until recently had front and rear castings plus structural battery pack.

Not sure about the Berlin BYD blade Model Y's but these could also use both castings as Berlin has produced both.

GhostSkater

Member

Oh my wallet, a guy that import battery cells here in Brazil got some 4680s, and so it just happens I'm in need of replacing the pack in one of my projects

My hand is itching, I need to check if I can make them fit, I really hope they don't

My hand is itching, I need to check if I can make them fit, I really hope they don't

dhanson865

Well-Known Member

TLSA's got the creepers in AH at 225+. Solid proof today that poetry has no effect.

Artful Dodger

"Neko no me"

trying to time the bottom

Tesla Inc TSLA:NASDAQ

After Hours: Last | 7:06 PM EST225.26 +1.55 (+0.69%)

Volume: 2,406,754

Similar threads

- Locked

- Replies

- 0

- Views

- 4K

- Locked

- Replies

- 0

- Views

- 6K

- Locked

- Replies

- 11

- Views

- 11K

- Replies

- 6

- Views

- 5K

- Locked

- Poll

- Replies

- 1

- Views

- 12K