MikeBur

ManualPilot

Below are some additional comparisons between the existing P85DL and Bill D's new Run1 . I've created a new sub-directory for these comparisons between Model S P85DL and P90DL in the Mikebur directory under "SP85DL to SP90DL compare...", or just click on this link: https://drive.google.com/open?id=0BzwKZAn3p2LTZXRIeVNaQ3R6aW8

I've also added Bill D's virtual drag strip calculations (thanks Bill ), though there appears to be something funky in calculations so hoping this is just because these are not full 1/4mile runs(?)

), though there appears to be something funky in calculations so hoping this is just because these are not full 1/4mile runs(?)

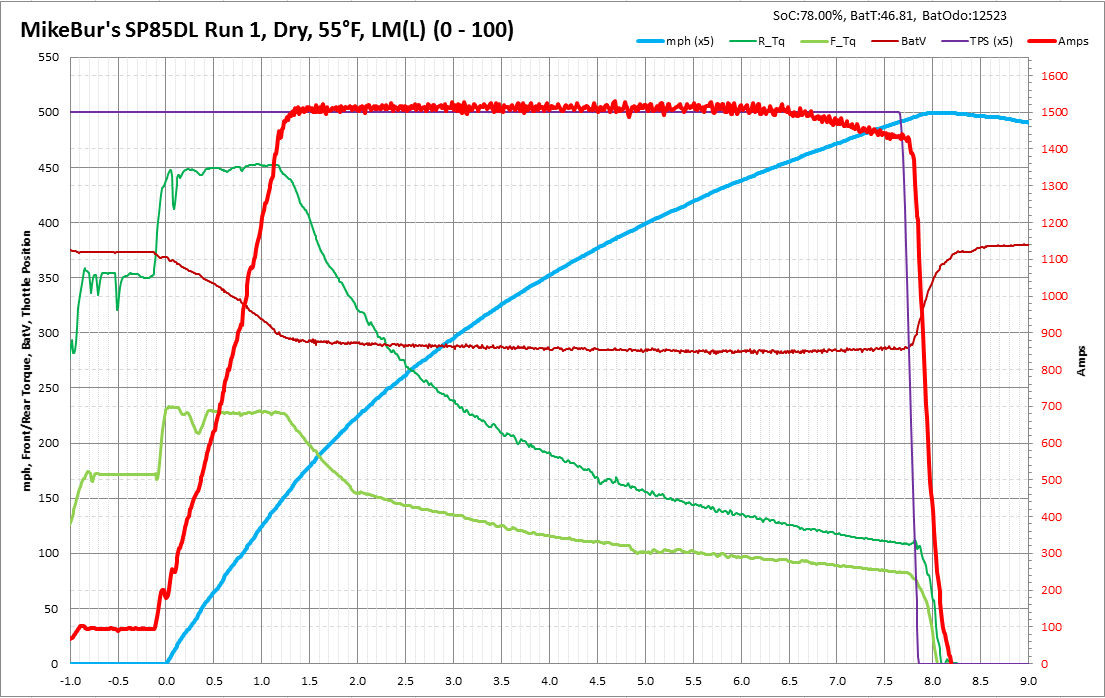

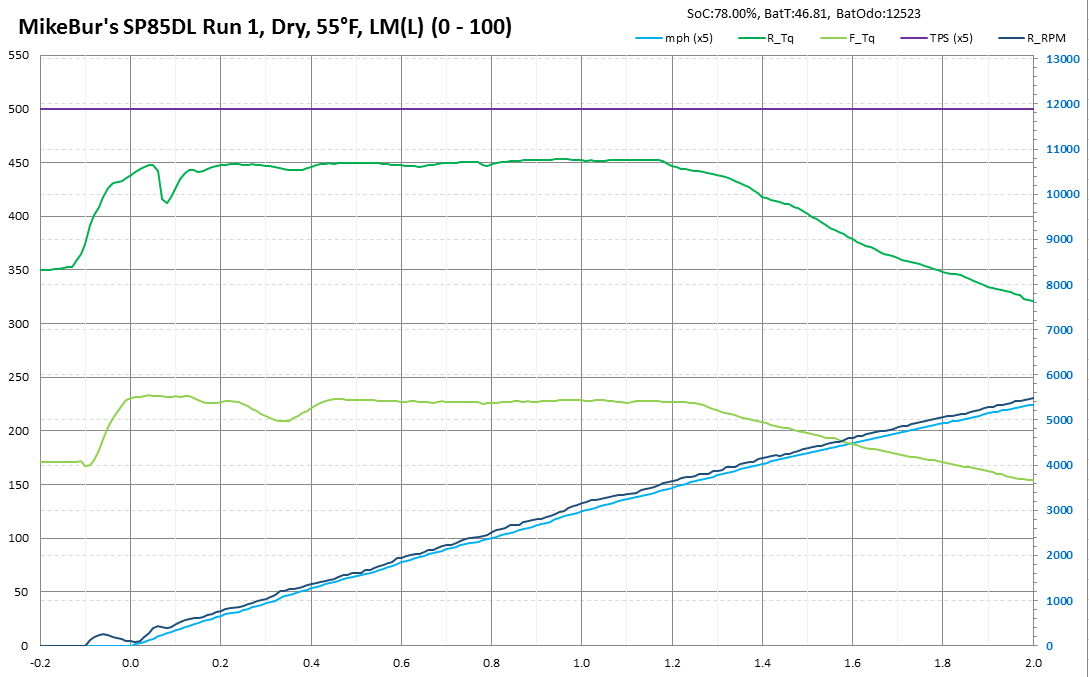

First, here's the original graph from mine to put all in one place for comparisons. Nothing new, though updated formatting to match Bill D...

Also, virtual drag timestrip numbers for 0-60 and rollout times now. Ignore 1000', etc.

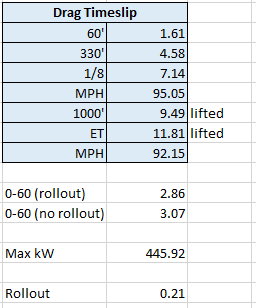

Ok, so back to comparing this run with the new run from Bill D, we can see significant similarity though the increased battery voltage, due to higher SoC, does makes more power available. It's too wet here currently for me to do a 95% SoC MaxBat run, so although a likely theory is not proven fact:

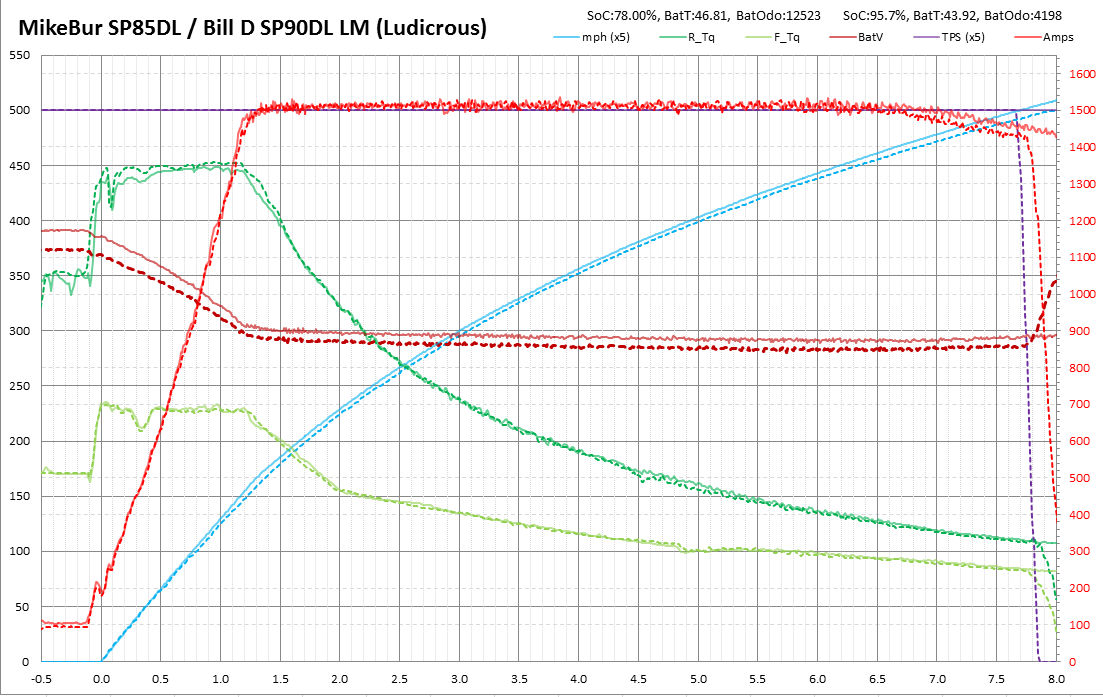

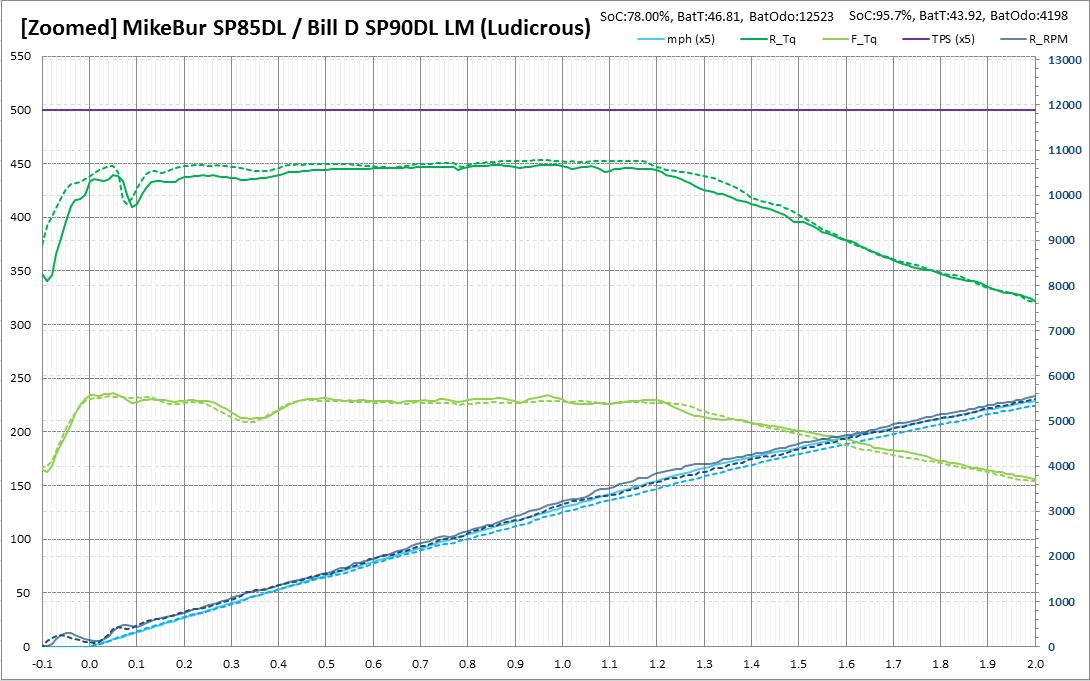

Zooming in on launch again appears to confirm that all available power is not being made available and this is not a traction limitation, otherwise we should see a steeper ramp on Bill D's higher SoC P90DL:

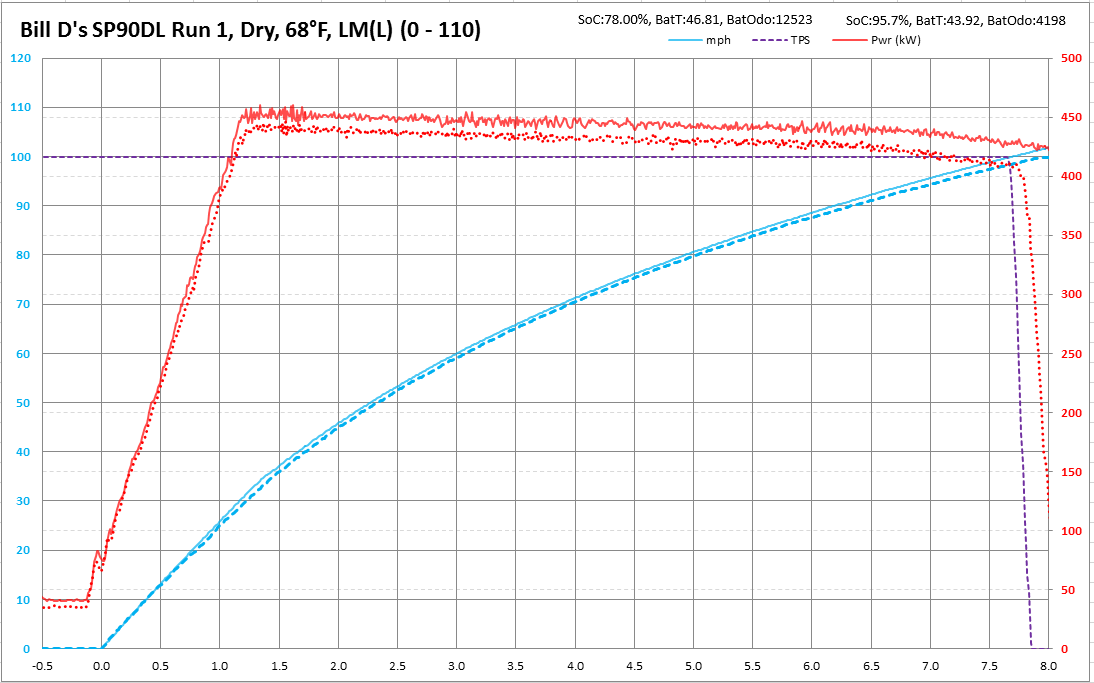

This becomes more apparent when looking at the Power, vs. doing the I*V by eye

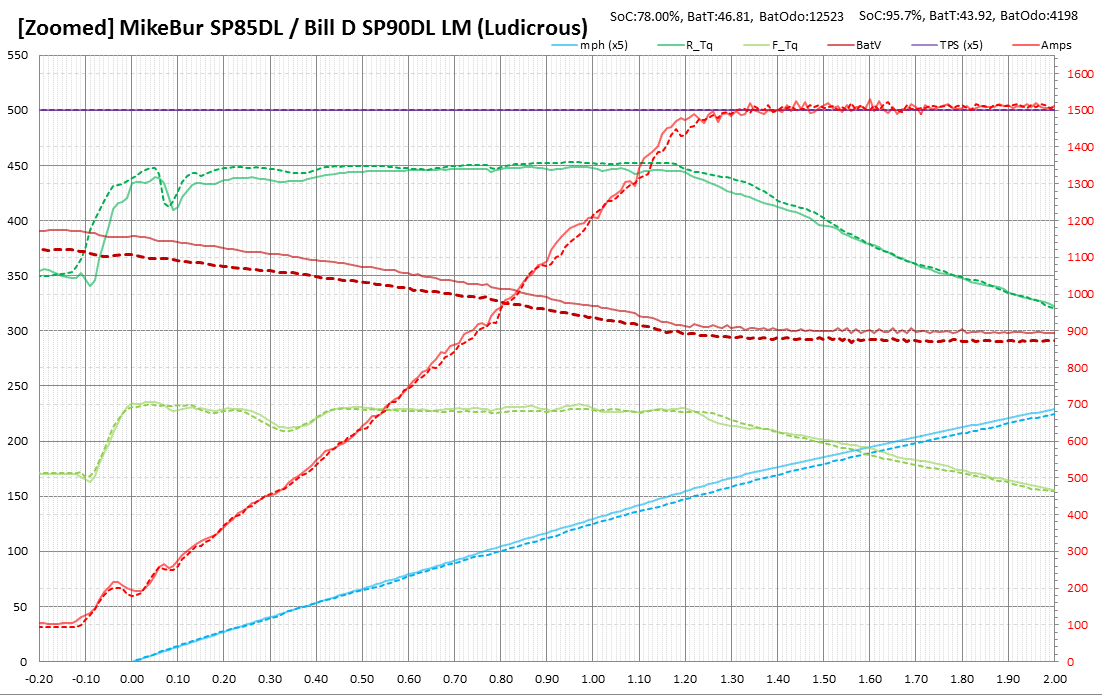

Bill D, when looking at the launch mode profiles, I agree that these are extremely similar, though I would rather posit that this is loading the tire sidewalls, rather than traction control - the shape of the RPM curve is very closely related to the blip we see in torque, ie. from the same run on my p85dl, the shape of these initial bumps are too coincidental for two different sets of wheels and tires at two different ambient temperatures to be coincidence. For launch mode, these are identical and for fast foot it also appears to be extremely similar (though smoother indicating this is the normal behavior vs. programmed behavior on launch):

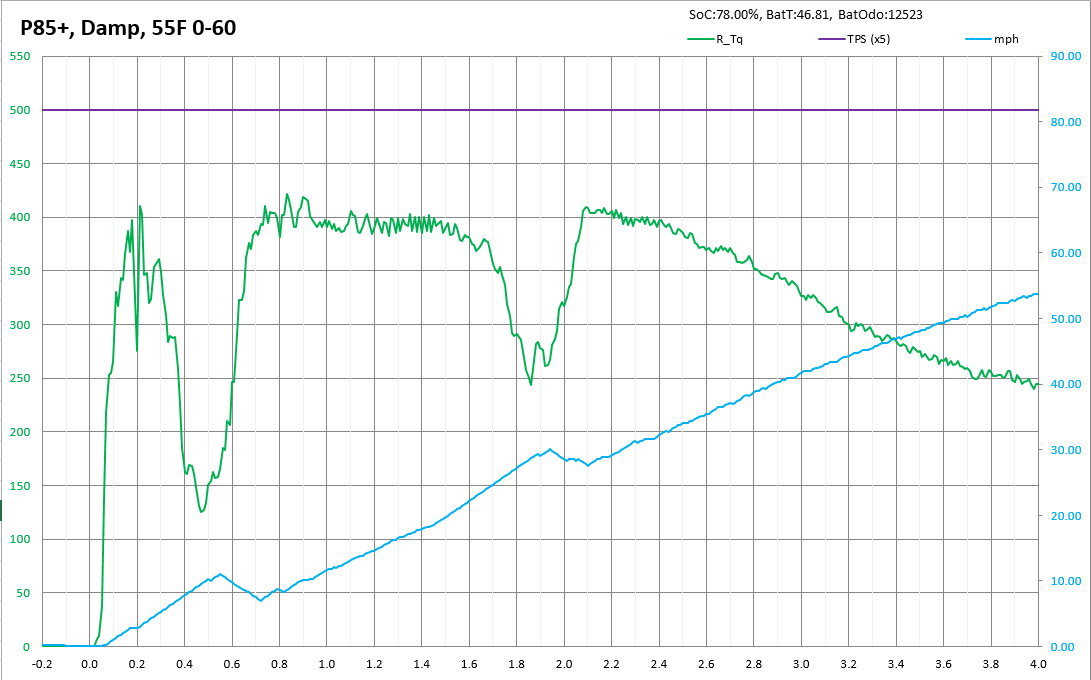

Comparing this to when traction control is engaged significantly (albeit this example from P85+ before R_RPM was captured) shows a very different characteristics of torque variation. Don't know exactly, though interesting nonetheless.

Just because I know someone will ask, how do our cars compare on the mph/rpm representation. To ruin the surprise almost the same again

Ok, this almost brings me back up to date, yes?

Hope this helps, Mike

I've also added Bill D's virtual drag strip calculations (thanks Bill

First, here's the original graph from mine to put all in one place for comparisons. Nothing new, though updated formatting to match Bill D...

Also, virtual drag timestrip numbers for 0-60 and rollout times now. Ignore 1000', etc.

Ok, so back to comparing this run with the new run from Bill D, we can see significant similarity though the increased battery voltage, due to higher SoC, does makes more power available. It's too wet here currently for me to do a 95% SoC MaxBat run, so although a likely theory is not proven fact:

Zooming in on launch again appears to confirm that all available power is not being made available and this is not a traction limitation, otherwise we should see a steeper ramp on Bill D's higher SoC P90DL:

This becomes more apparent when looking at the Power, vs. doing the I*V by eye

Bill D, when looking at the launch mode profiles, I agree that these are extremely similar, though I would rather posit that this is loading the tire sidewalls, rather than traction control - the shape of the RPM curve is very closely related to the blip we see in torque, ie. from the same run on my p85dl, the shape of these initial bumps are too coincidental for two different sets of wheels and tires at two different ambient temperatures to be coincidence. For launch mode, these are identical and for fast foot it also appears to be extremely similar (though smoother indicating this is the normal behavior vs. programmed behavior on launch):

Comparing this to when traction control is engaged significantly (albeit this example from P85+ before R_RPM was captured) shows a very different characteristics of torque variation. Don't know exactly, though interesting nonetheless.

Just because I know someone will ask, how do our cars compare on the mph/rpm representation. To ruin the surprise almost the same again

Ok, this almost brings me back up to date, yes?

Hope this helps, Mike