Welcome to Tesla Motors Club

Discuss Tesla's Model S, Model 3, Model X, Model Y, Cybertruck, Roadster and More.

Register

Install the app

How to install the app on iOS

You can install our site as a web app on your iOS device by utilizing the Add to Home Screen feature in Safari. Please see this thread for more details on this.

Note: This feature may not be available in some browsers.

-

Want to remove ads? Register an account and login to see fewer ads, and become a Supporting Member to remove almost all ads.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Teslawisher

Member

I've been hoping for this for a while. Can you just imagine the gas and maintenance savings? Push it out to DOT's on top of commercial business also. The buget savings and environmental impacts grow exponentially.

gavine

Petrol Head turned EV Enthusiast

N4HHE

Member

Thats nice but its mostly a fool's errand. A Model S weighs 5,000 pounds to serve for what would be 3,000 in a conventional automobile and has a relatively small payload capacity. Don't have that margin in trucks. Model S payload is roughly the same as its battery. Can't carry another 40,000 pounds in an OTR truck. And what about charging?

Believe its Eaton who has an interesting solution for start/stop service such as garbage trucks. They hydraulically compress a spring when stopping and use the stored energy to get moving to the next house for pickup.

Believe its Eaton who has an interesting solution for start/stop service such as garbage trucks. They hydraulically compress a spring when stopping and use the stored energy to get moving to the next house for pickup.

This is not a fool's errand.

If you read the article, they are starting with garbage trucks. That is a good place to start and electric drive can succeed there right now.

Garbage trucks run the exact same route week to week. You know exactly how long each days route is. The service area is very small. They don't drive very fast. The payload is also very consistent. They return to a central depot regularly, which is a good place to charge. The schedule can be managed to include charging time, dedicated charging locations can be placed in the service area, scheduled ahead of time, and shared by the trucks.

After that buses and local delivery trucks ( think UPS ) should be next. Buses are very similar to garbage trucks.

UPS has such a huge fleet of trucks and so many packages to schedule that they could select a portion of the routes to be served by electric trucks. The routes may vary, but with a large fleet they can optimize the problem, and reserve gas trucks for the least dense long routes.

Electric drive technology will have to progress a lot before it can do long haul trucks that are not in a fleet, but there is plenty to do before we get to that.

If you read the article, they are starting with garbage trucks. That is a good place to start and electric drive can succeed there right now.

Garbage trucks run the exact same route week to week. You know exactly how long each days route is. The service area is very small. They don't drive very fast. The payload is also very consistent. They return to a central depot regularly, which is a good place to charge. The schedule can be managed to include charging time, dedicated charging locations can be placed in the service area, scheduled ahead of time, and shared by the trucks.

After that buses and local delivery trucks ( think UPS ) should be next. Buses are very similar to garbage trucks.

UPS has such a huge fleet of trucks and so many packages to schedule that they could select a portion of the routes to be served by electric trucks. The routes may vary, but with a large fleet they can optimize the problem, and reserve gas trucks for the least dense long routes.

Electric drive technology will have to progress a lot before it can do long haul trucks that are not in a fleet, but there is plenty to do before we get to that.

There are already electric garbage trucks, buses and delivery trucks. What are they bringing new to the party?

JER

Member

Wrightspeed's tech is actually a plug in series hybrid (i.e. a REV) with a gas turbine generator. That keeps the cost and mass of the battery and generator to reasonable levels, while having minimal service requirements and very long service life. They recently announced their own (more efficient) in-house generator design with integrated recuperator.

Apparently, it's a lot easier to meet emissions requirements with a gas turbine than a piston engine. Theirs beats current limits with no catalyst and no urea injection.

The regen is another big deal for multi-drop use. Their system provides hard braking under regen with a unique traction control system to maintain stability. As well as contributing to fuel efficiency, this also means big saving on servicing the brakes - usually a major cost in that work cycle.

Another interesting trick up its sleve is near-instant, clutchless gearchanges using the PEM software to sync motor to road speed. The system has two ratios in order to meet the torque and speed range specifications for a heavy truck.

Apparently, it's a lot easier to meet emissions requirements with a gas turbine than a piston engine. Theirs beats current limits with no catalyst and no urea injection.

The regen is another big deal for multi-drop use. Their system provides hard braking under regen with a unique traction control system to maintain stability. As well as contributing to fuel efficiency, this also means big saving on servicing the brakes - usually a major cost in that work cycle.

Another interesting trick up its sleve is near-instant, clutchless gearchanges using the PEM software to sync motor to road speed. The system has two ratios in order to meet the torque and speed range specifications for a heavy truck.

Last edited:

J

jbcarioca

Guest

I wonder how they deal with the inherent fuel inefficiency of gas turbines. Thus far turbines have been cost effective only in a few specialised applications, most notably aircraft where the triple advantages of very low weight, very high reliability and tolerance of fuel impurities have made them ubiquitous. They still have not come anywhere near ICE, specifically diesel, in terms of fuel efficiency. I'm perplexed.Gas turbine is interesting... I wonder how loud the thing is.

AntronX

Member

I wonder how they deal with the inherent fuel inefficiency of gas turbines...

Take a look at Capstone turbine product catalog on this page. Their smallest 28KWe NG turbine gets 25% electrical efficiency. That's comparable to regular non hybrid gasoline engine. Prius engine has peak efficiency of 36% mechanical, or about 32% electrical with 90% efficient generator.

gavine

Petrol Head turned EV Enthusiast

Turbines are best for constant speed applications. I always thought that Chevy should have used a turbine for the range extender.

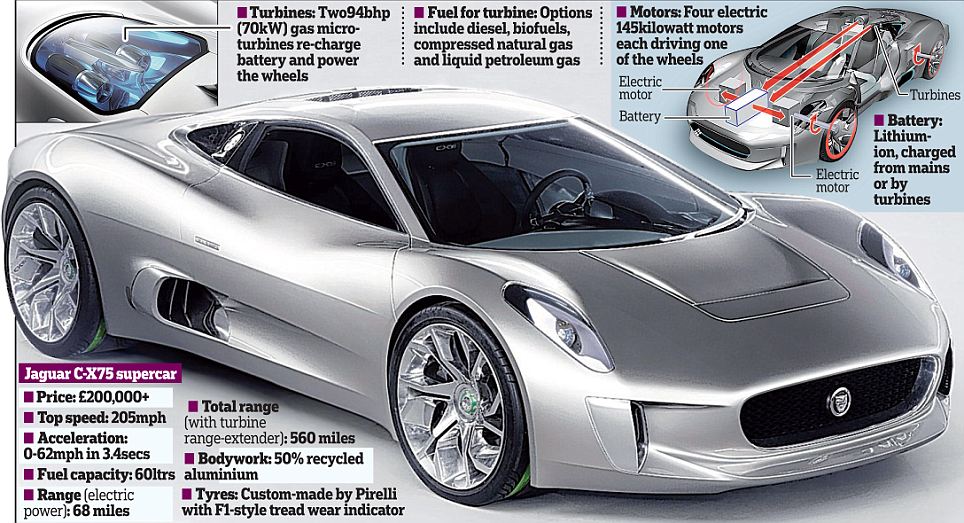

Jaguar toyed with the idea:

Jaguar toyed with the idea:

JER

Member

The main reason for gas turbine is that a piston powered generator rated for the same duty cycle and lifespan weighs about ten times as much and occupies a lot more volume. Piston engines can do high power density or high duty cycle, but not both - not without wearing out really fast, anyway.

As for efficiency, Ian Wright concedes that it's really hard to match piston engines. However, their own design (called "Fulcrum") has a good stab at it: Fulcrum has a two-stage compressor with intercooler and an exhaust gas to pre-combustion recuperator with an unusual design. I've not heard an official figure for thermodynamic efficiency, but I'd bet it's higher than 25%. Their website claims "substantially more efficient than single-stage microturbines"

As for noise, it's bound to be quieter (and produce far less vibration than) a piston engine. With combustion and expansion being a continuous process, there'll be less sound pressure for the muffler system to absorb.

FYI, Fulcrum’s output is 80kWe. It weighs about 120kg including the recuperator and generator, and has a claimed service life of 10,000 hours - though Ian mentioned 40k hours for the turbine in an interview.

As for efficiency, Ian Wright concedes that it's really hard to match piston engines. However, their own design (called "Fulcrum") has a good stab at it: Fulcrum has a two-stage compressor with intercooler and an exhaust gas to pre-combustion recuperator with an unusual design. I've not heard an official figure for thermodynamic efficiency, but I'd bet it's higher than 25%. Their website claims "substantially more efficient than single-stage microturbines"

As for noise, it's bound to be quieter (and produce far less vibration than) a piston engine. With combustion and expansion being a continuous process, there'll be less sound pressure for the muffler system to absorb.

FYI, Fulcrum’s output is 80kWe. It weighs about 120kg including the recuperator and generator, and has a claimed service life of 10,000 hours - though Ian mentioned 40k hours for the turbine in an interview.

There are already electric garbage trucks, buses and delivery trucks. What are they bringing new to the party?

Tesla co-founder Ian Wright is transforming garbage trucks into electric green machines | Inhabitat - Sustainable Design Innovation, Eco Architecture, Green Building

Bangor Bob

Member

The regen is another big deal for multi-drop use. Their system provides hard braking under regen with a unique traction control system to maintain stability. As well as contributing to fuel efficiency, this also means big saving on servicing the brakes - usually a major cost in that work cycle.

This apparently is one of the big pluses of the Wrightspeed retrofits, the garbage trucks reportedly use their brakes to the point of activating the ABS systems, hundreds of times per day. Normal brake service intervals are measured in weeks, not months. Service intervals after conversion goes way up.

The trucks are supposed to be much quieter as well, especially when using the hydraulic lifts, which is of benefit to the garbage company's customers (and their neighbors).

Similar threads

- Replies

- 70

- Views

- 4K

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 855