If you are like me and living in New England where the roads are salted 4 months out of the year if not more, you're a bit paranoid about rust. An ostensibly well rust proofed from the factory Lexus showed pretty extensive rust after 10 years in New England, adding to my paranoia in the context of Tesla's well documented quality control issues. My paranoia about this was not helped when I saw that there was already rust on the stainless steel hub of the front wheel, after just a month and even before any winter time salt had any opportunity to wreak havoc.

So I decided to investigate undercoating and rustproofing - as much as one can do that - of the undercarriage and suspension parts, starting at the rear. This for sure is not as glamorous as getting new wheels, tires, or coilovers, but you'll be glad you did it 5, 8, and 15 years down the road if you keep the car that long.

Here's what I did and what you will need to duplicate it - and it turned out to be surprisingly easy:

1) 8 cans of Rust-Oleum rubberized undercoating, readily available at Walmart, AutoZone, and on Amazon. Any rubberized undercoating will work pretty much just as well as Rust-Oleum but it's more widely available.

2) 2 cans of CRC, also available on Amazon.

3) Jack the car up safely preferably using a jack pad, and take off the rear tire.

4) remove the liners inside the rear wheel wells which are held on with a connection of screw posts and snap in clips.

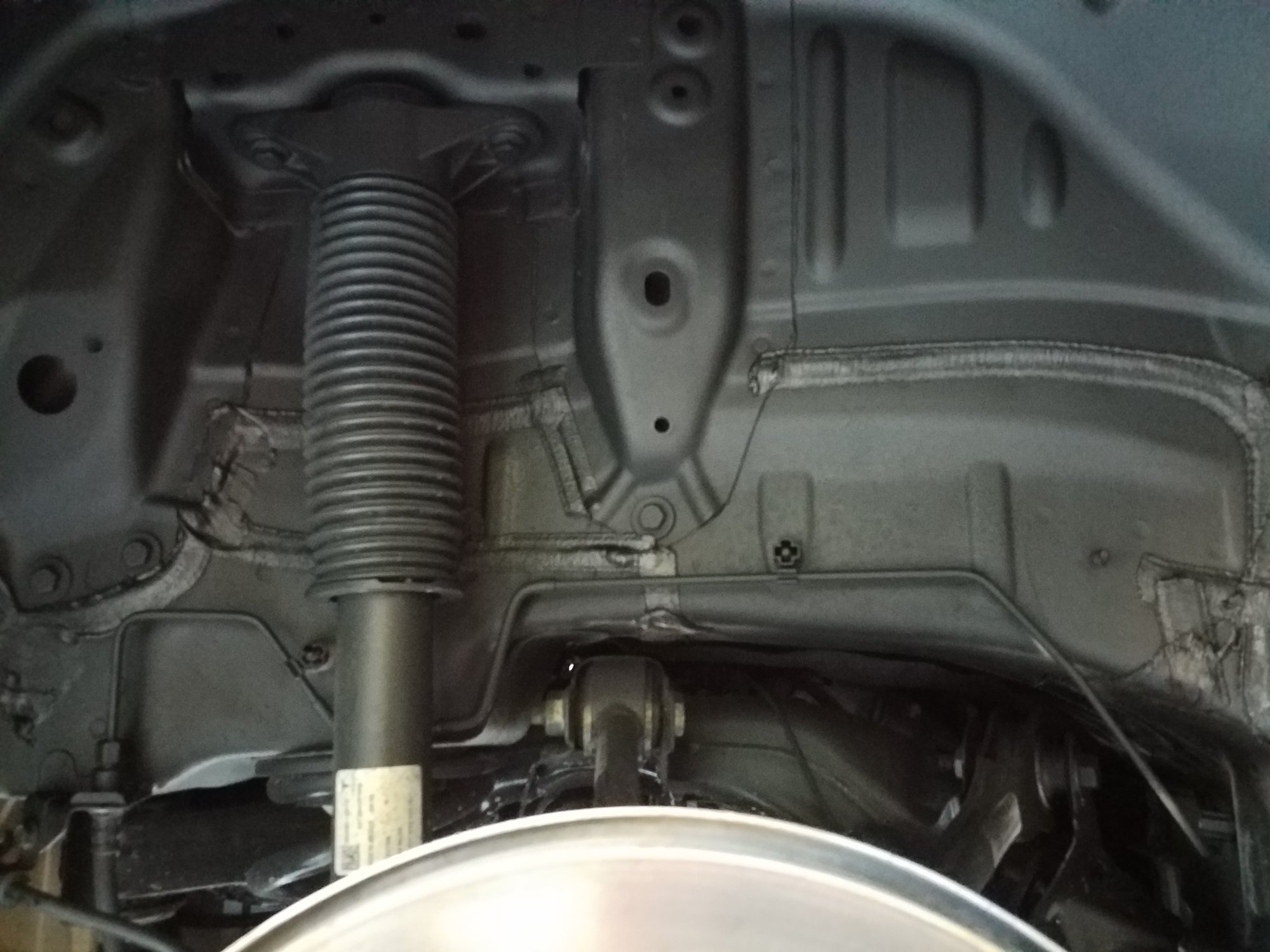

5) you will now have access to sheet metal what you will see presumably coated with some kind of electrically deposited primer. And you will also have access to the rear suspension without as much obstruction. You can see in this first picture how sheet metal looks prior to rubberized undercoating and afterwards as well.

6) take the CRC and spread on all exposed suspension bolts and nuts and any other ferric metal, but avoid wiring

7) take the fibrous and frankly somewhat flimsy interior wheel well liners out carefully, making sure you don't tear them. You may have to cut them at the top seam as it appears they were glued together from two separate sections. Don't worry about cutting them because it's easy to join the back together at the top what you will do on reinstallation.

8) take one entire can of rubberized undercoating and liberally coat the inside of the fibrous wheel-well liners. This will make them both more durable and potentially somewhat more absorbing of road noise which is an issue in any case with this car despite it having a very quiet drivetrain.

9) wait about an hour at least for these to dry completely and carefully reinstall using clips and screw posts. Probably a good idea to pick up some extra clips which are 8 mm in size and actually are identical to what Honda uses - you can get these at any AutoZone for a few bucks and you'll use them up anyway as they have a tendency to pop off.

10) optionally, you can clean out the underneath tray which is full of sand and Grit. It's a bit worrisome how much junk gets in there. There are already threads on this issue. This is on a car with only a couple of thousand miles so you can imagine how much sand and grit gets in there after a year.

So I decided to investigate undercoating and rustproofing - as much as one can do that - of the undercarriage and suspension parts, starting at the rear. This for sure is not as glamorous as getting new wheels, tires, or coilovers, but you'll be glad you did it 5, 8, and 15 years down the road if you keep the car that long.

Here's what I did and what you will need to duplicate it - and it turned out to be surprisingly easy:

1) 8 cans of Rust-Oleum rubberized undercoating, readily available at Walmart, AutoZone, and on Amazon. Any rubberized undercoating will work pretty much just as well as Rust-Oleum but it's more widely available.

2) 2 cans of CRC, also available on Amazon.

3) Jack the car up safely preferably using a jack pad, and take off the rear tire.

4) remove the liners inside the rear wheel wells which are held on with a connection of screw posts and snap in clips.

5) you will now have access to sheet metal what you will see presumably coated with some kind of electrically deposited primer. And you will also have access to the rear suspension without as much obstruction. You can see in this first picture how sheet metal looks prior to rubberized undercoating and afterwards as well.

6) take the CRC and spread on all exposed suspension bolts and nuts and any other ferric metal, but avoid wiring

7) take the fibrous and frankly somewhat flimsy interior wheel well liners out carefully, making sure you don't tear them. You may have to cut them at the top seam as it appears they were glued together from two separate sections. Don't worry about cutting them because it's easy to join the back together at the top what you will do on reinstallation.

8) take one entire can of rubberized undercoating and liberally coat the inside of the fibrous wheel-well liners. This will make them both more durable and potentially somewhat more absorbing of road noise which is an issue in any case with this car despite it having a very quiet drivetrain.

9) wait about an hour at least for these to dry completely and carefully reinstall using clips and screw posts. Probably a good idea to pick up some extra clips which are 8 mm in size and actually are identical to what Honda uses - you can get these at any AutoZone for a few bucks and you'll use them up anyway as they have a tendency to pop off.

10) optionally, you can clean out the underneath tray which is full of sand and Grit. It's a bit worrisome how much junk gets in there. There are already threads on this issue. This is on a car with only a couple of thousand miles so you can imagine how much sand and grit gets in there after a year.