There's been a lot of talk about less-than-ideal charge speeds at the V3 superchargers in colder climates, so I decided to log the session.

I drove about 90 minutes and arrived at my in-laws house and had lunch, so the car sat idle for 90 minutes. The battery pack was at 64F at the end of the drive, 17% SoC.

I entered the Tesla supercharger location in the NAV to start the pre-conditioning process. Battery pack was at 51F, so a drop of 13F. UI was displaying the snow flake icon, 11% SoC displayed on the UI, 14% displayed in Scan My Tesla app. After about 8 minutes, the snow flake icon disappeared when the battery pack temp reached around 58F. In hindsight, I should've logged the pre-conditioning drive to the supercharger to show all this data. A few random things I've noted: the front stator motor only gets to around 120F during the process, consuming 2 kW. This isn't as effective as preconditioning parked, where the front motor can reach 210F. During the 20 minute drive to the supercharger, the battery pack went from 51F to 68F, which is well below what is needed to see the full speeds at a Level 3 charger. Ideally you want the battery pack to be closer to 100F if you want to see the full charging speeds.

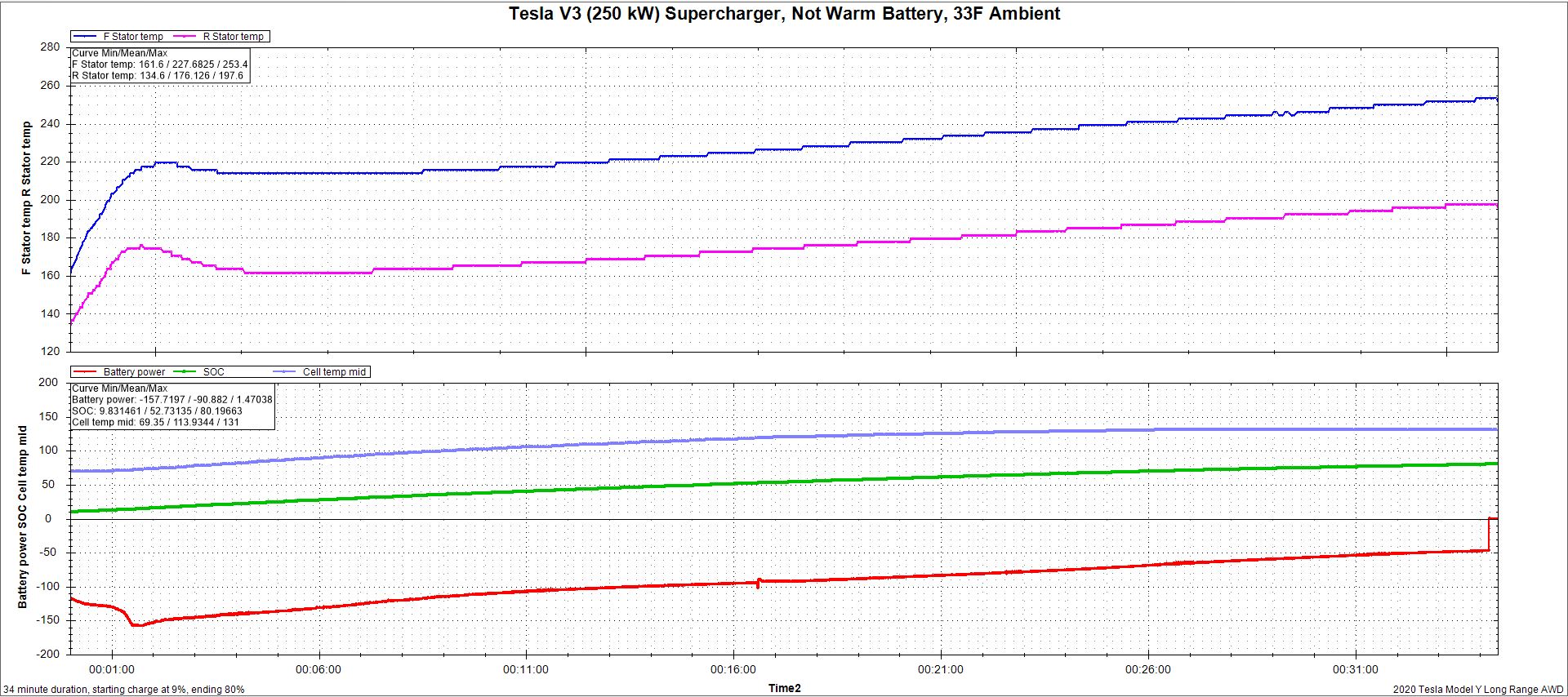

Below is the graph of the charging session. As noted in the title and footers, the ambient temp was 33F, wind 10-15 mph, with gusts up to 25F. I started the charge at 9.8% SoC, ended at 80%, total duration of 33 minutes.

You can see the stator motors quickly heating up and within 2 minutes the front motors were at 219F, the rear motors were at 176F. The battery packs started at 69F, ended at 131F.

In about 90 seconds after plugging in is where I saw the max charge rate of only 157 kW and then tapering off over time, as shown on the graph. I noted where the 20% SoC is on the graph. At that point, the battery packs were only 80F, or around 3.5 minutes into the charge. The battery packs hit the optimal temp of 100F a little after 9 minutes but by then, the SoC was at 35% and the BMS had already started throttling back the charge to 113 kW.

I'll do more logs when it gets warmer out so we can see how these all behave when the packs are already at 90+ F at the start of the charge.

I drove about 90 minutes and arrived at my in-laws house and had lunch, so the car sat idle for 90 minutes. The battery pack was at 64F at the end of the drive, 17% SoC.

I entered the Tesla supercharger location in the NAV to start the pre-conditioning process. Battery pack was at 51F, so a drop of 13F. UI was displaying the snow flake icon, 11% SoC displayed on the UI, 14% displayed in Scan My Tesla app. After about 8 minutes, the snow flake icon disappeared when the battery pack temp reached around 58F. In hindsight, I should've logged the pre-conditioning drive to the supercharger to show all this data. A few random things I've noted: the front stator motor only gets to around 120F during the process, consuming 2 kW. This isn't as effective as preconditioning parked, where the front motor can reach 210F. During the 20 minute drive to the supercharger, the battery pack went from 51F to 68F, which is well below what is needed to see the full speeds at a Level 3 charger. Ideally you want the battery pack to be closer to 100F if you want to see the full charging speeds.

Below is the graph of the charging session. As noted in the title and footers, the ambient temp was 33F, wind 10-15 mph, with gusts up to 25F. I started the charge at 9.8% SoC, ended at 80%, total duration of 33 minutes.

You can see the stator motors quickly heating up and within 2 minutes the front motors were at 219F, the rear motors were at 176F. The battery packs started at 69F, ended at 131F.

In about 90 seconds after plugging in is where I saw the max charge rate of only 157 kW and then tapering off over time, as shown on the graph. I noted where the 20% SoC is on the graph. At that point, the battery packs were only 80F, or around 3.5 minutes into the charge. The battery packs hit the optimal temp of 100F a little after 9 minutes but by then, the SoC was at 35% and the BMS had already started throttling back the charge to 113 kW.

I'll do more logs when it gets warmer out so we can see how these all behave when the packs are already at 90+ F at the start of the charge.